Vertical two-sided shooting target

A vertical and double-sided technology, applied in the field of shooting targets, can solve the problems of unstable rebound, short service life, and low utilization rate of the target machine, and achieve the effect of facilitating shooting performance, improving service life and preventing bullet damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

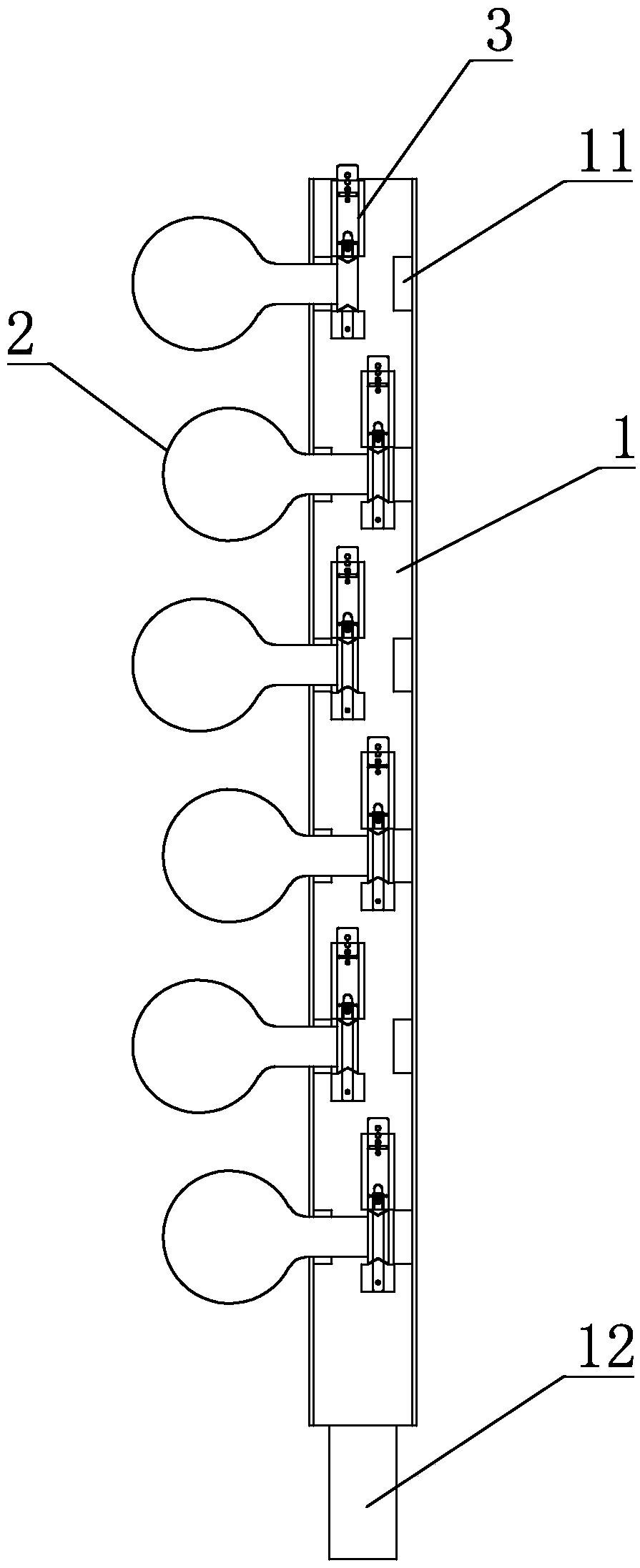

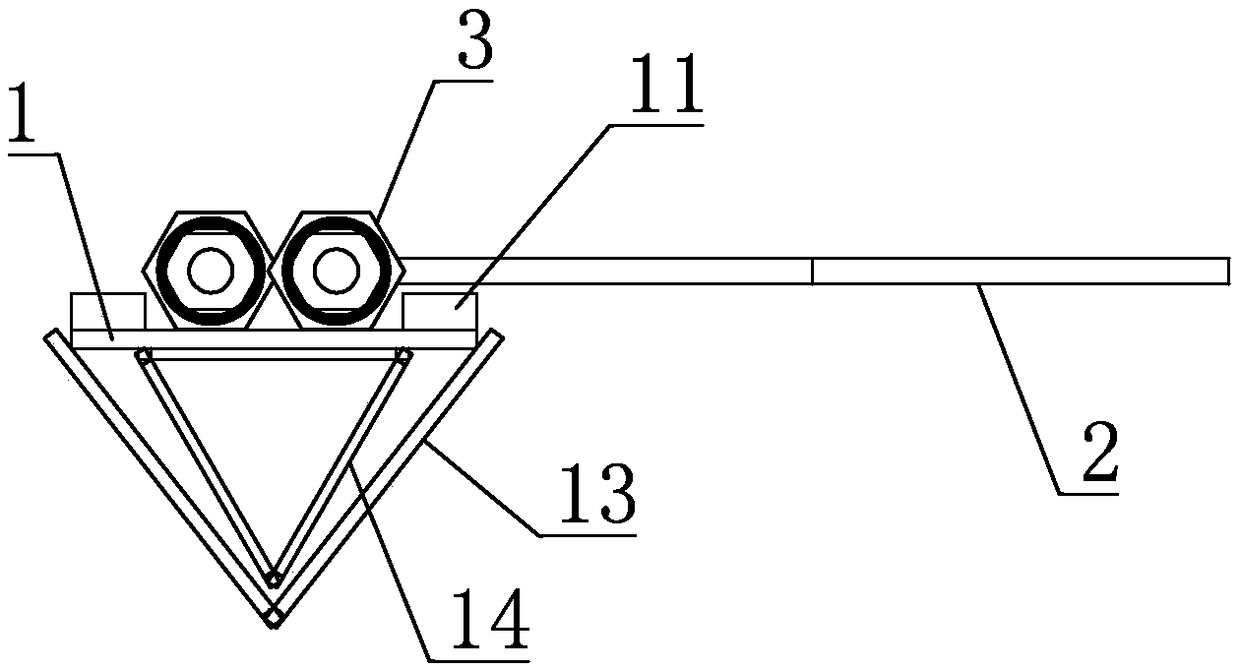

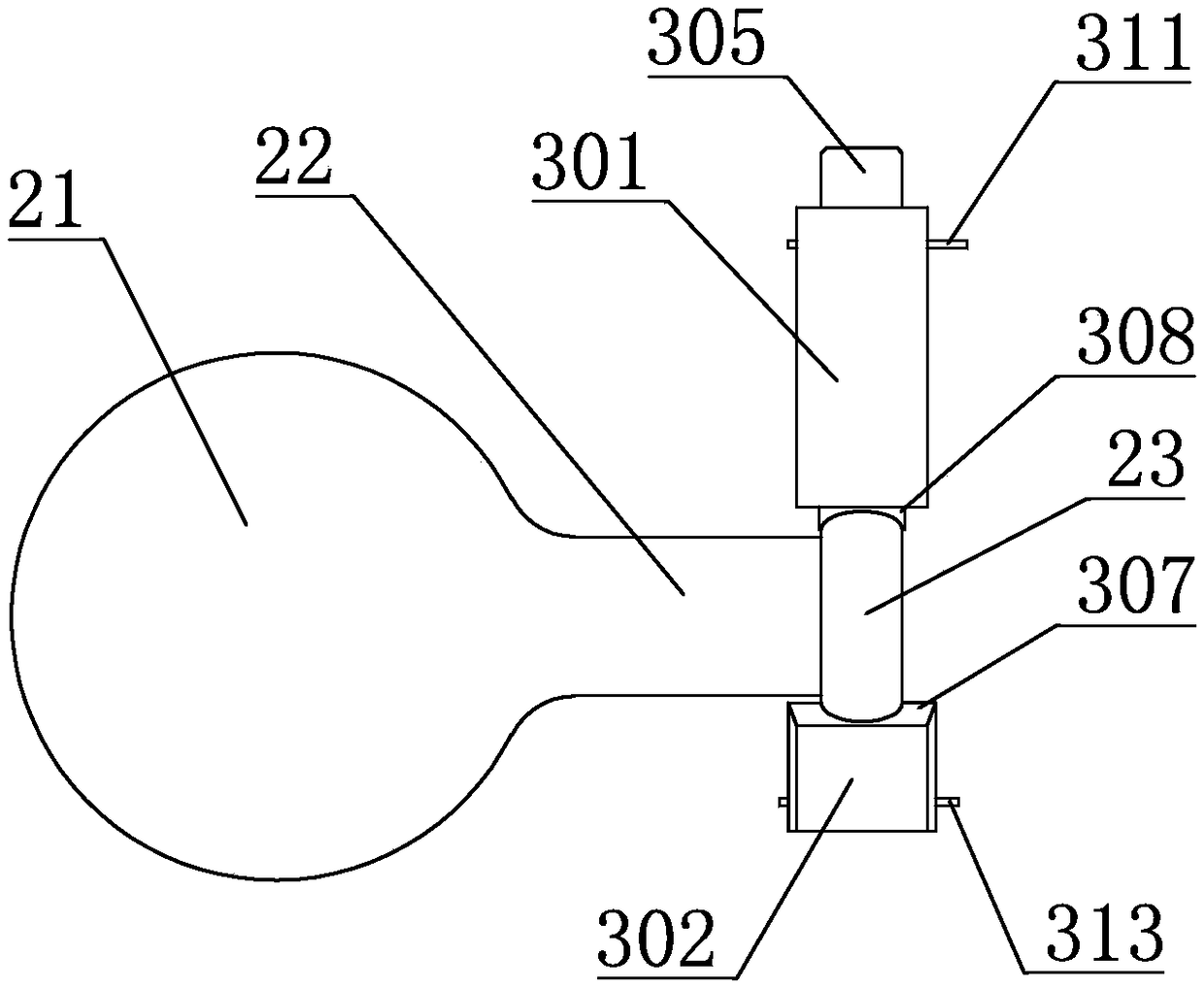

[0022] refer to Figure 1 to Figure 5 , a vertical double-sided shooting target of the present invention, comprising a vertical target column 1 and a plurality of steel targets 2 vertically arranged on the vertical target column 1, the rear side of the vertical target column 1 is provided with a plurality of longitudinal The rotating shaft assembly 3 arranged and corresponding to the steel target 2 one-to-one, the steel target 2 can swing left and right through the rotating shaft assembly 3 and is installed on the rear side of the vertical target post 1, so that when shooting practice, the bullet hits the steel target 2 The impact force will drive the steel target 2 to rotate around the rotating shaft assembly 3, so that the steel target 2 swings to the other side of the vertical target column 1, so that the other side of the steel target 2 can continue to be shot with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com