Continuous reverse extraction system

A stripping agent and extraction technology, used in solvent extraction, liquid solution solvent extraction, chemical instruments and methods, etc., can solve the problems of flow rate, difficult application and high system maintenance cost in membrane blockage treatment

Pending Publication Date: 2019-01-29

XINJIANG SHENBANG ENVIRONMENTAL ENG CO LTD

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this decolorization system, due to the fact that the tubular membrane is often clogged during use, the flow rate of the treatment is reduced, and it must be flushed frequently to recover.

Therefore, although the system can achieve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

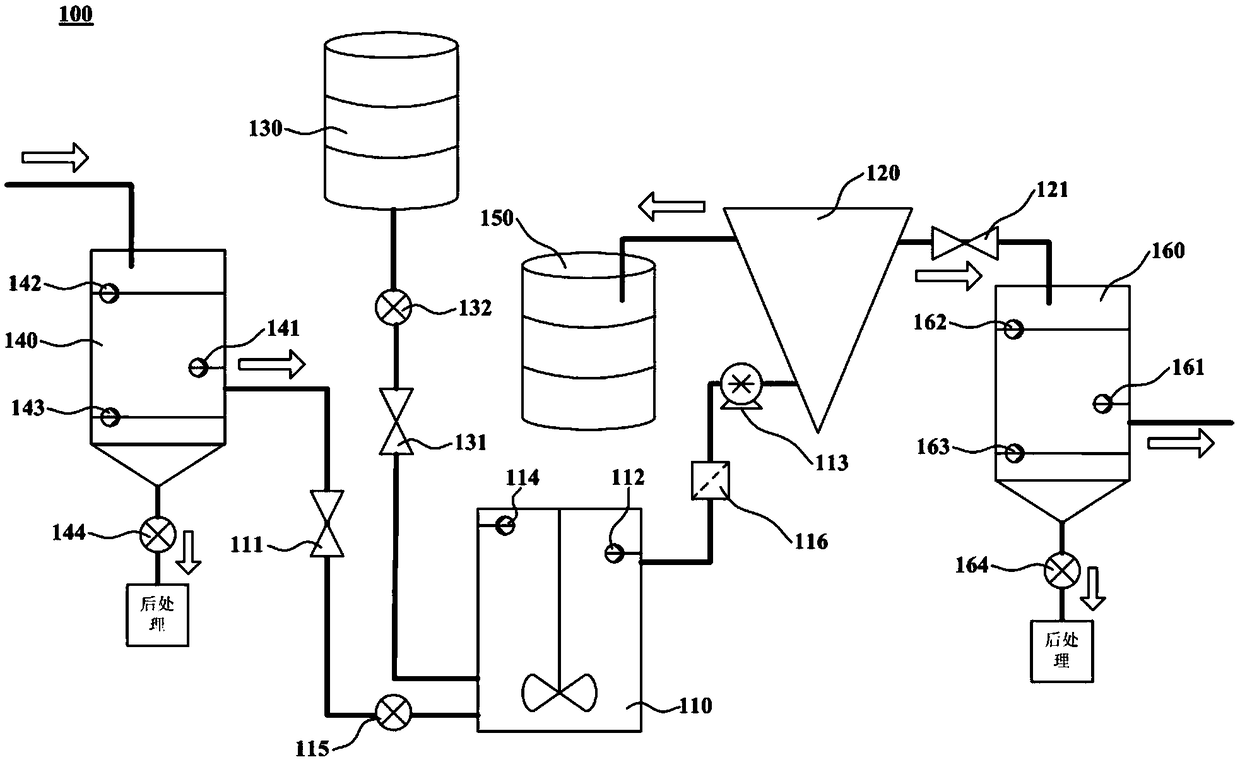

The invention provides a continuous reverse extraction system. The system is in fluid connection with an extraction system. The continuous reverse extraction system comprises a reverse extraction mixing device, a separating device and a stripping agent storage device, wherein the reverse extraction mixing device is in fluid connection with the extraction system, and is used for receiving color oildischarged by the extraction system, the separating device is separately in fluid connection with the reverse extraction mixing device, a dye collecting device and a net oil collecting device, and the reverse extracting agent storage device is in fluid connection with the reverse extraction mixing device, and is used for providing a stripping agent for the reverse extraction mixing device.

Description

technical field [0001] The invention relates to the field of printing and dyeing wastewater treatment, in particular to a continuous stripping system used in the process of decolorization and reuse of residual dyeing baths. Background technique [0002] Reactive dyes are the most commonly used dyes for cotton dyeing because of their bright colors, good fastness, low price, and easy use. However, during the dyeing process, a considerable part (about 30%) of reactive dyes will be hydrolyzed. In order to make the hydrolyzed dye easy to wash off after dyeing and prevent the dye fastness from being attached to the cotton fiber, the molecular structure of the reactive dye is designed to have a low affinity to the cotton fiber. This molecular structure reduces the adsorption of reactive dyes to fibers during the dyeing process, which affects the use efficiency of dyes. [0003] In order to enable reactive dyes to effectively dye cotton fibers, a large amount of salt must be added...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D11/04

CPCB01D11/04B01D11/0488

Inventor 刘奎东李世琪

Owner XINJIANG SHENBANG ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com