A floating tank-tyre type floating breakwater unit and breakwater system capable of sinking and floating under extreme sea conditions

A technology of floating breakwaters and breakwaters, applied in the direction of breakwaters, embankments, jetties, etc., can solve the problems of poor wave absorption effect and difficulty in self-protection of floating breakwater structures, and achieve the effect of increasing project cost, reducing cost, and reducing wave load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in combination with specific embodiments.

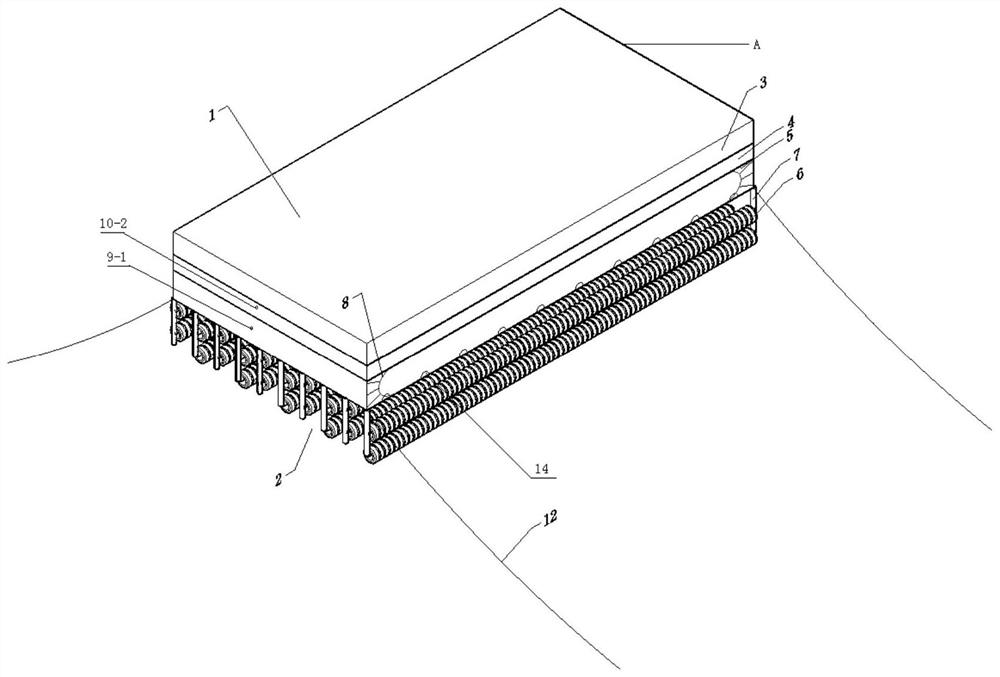

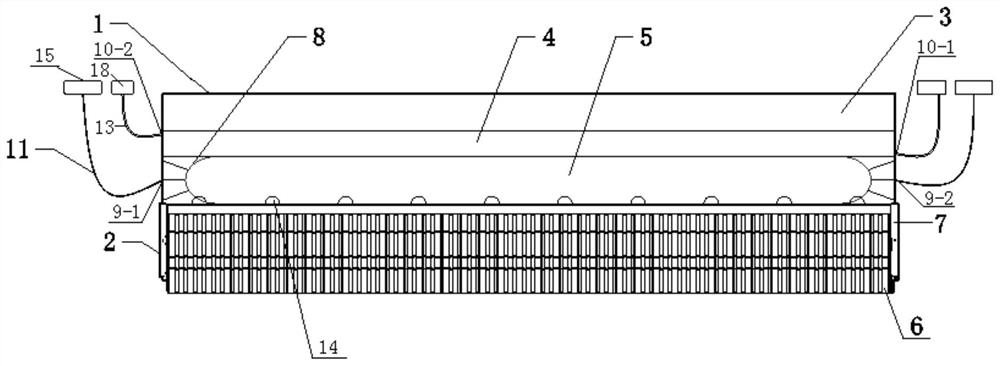

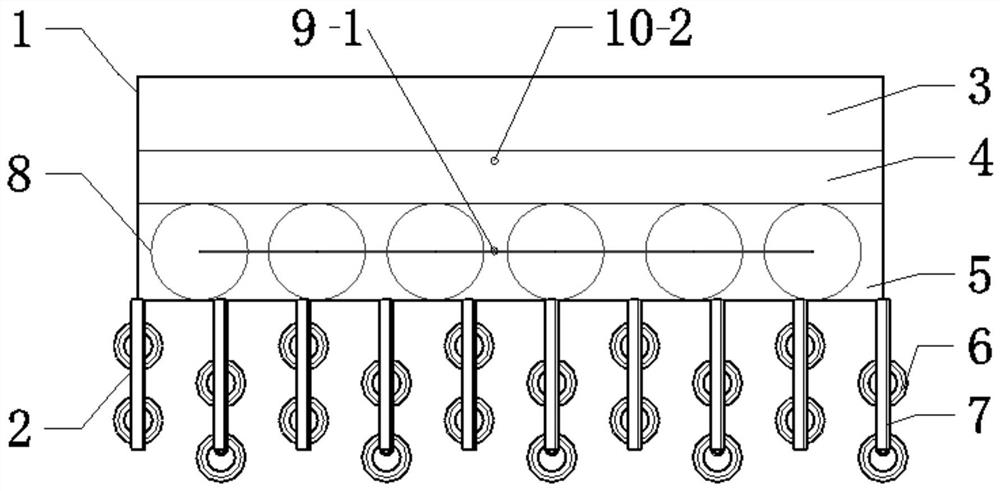

[0024] like Figure 1~3 As shown, the breakwater unit A of the present invention, the breakwater unit A is composed of a floating body part 1 and an underwater part 2; wherein, the floating body part 1 is composed of an upper sealed empty tank 3, a middle layer ballast water tank 4 and a lower layer airbag box 5, and the upper layer sealed empty tank 3. The middle ballast water tank 4 and the lower airbag box 5 are fixed and connected in turn by bolts; the upper sealed empty tank 3, the middle ballast water tank 4 and the lower airbag box 5 are all rectangular parallelepiped structures made of steel plates and engineering plastics; the three boxes The construction of the body is carried out separately. After the construction is completed, the floating body part 1 is fixed by bolts; the upper sealed empty tank 3 is divided into multiple compartment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com