Jet type borehole cleaning tool

A cleaning tool and jet technology, which is applied in the direction of flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problems of increasing drilling time, increasing drilling operation cost, increasing friction, etc., and achieving chip carrying capacity Enhanced, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

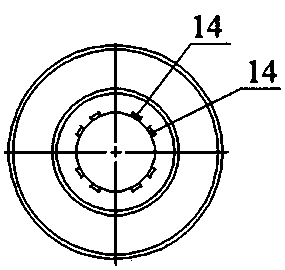

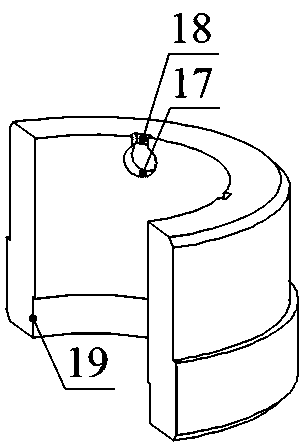

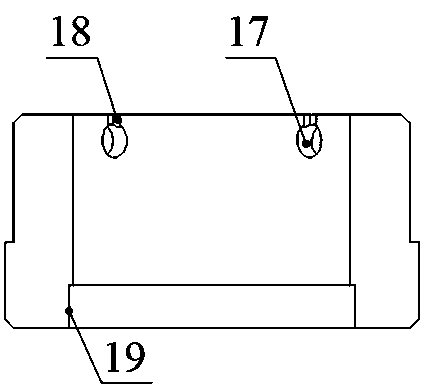

[0029] like figure 1 As shown, this jet type wellbore cleaning tool includes a casing joint 1, a valve block 3, a sliding block 4, a rubber switch 7, a rotating disk 6, and a lower joint 9; the lower joint 9 is fastened to the lower end of the shell joint 1 by threads, and the lower see link Figure 9 , the upper end of the shell joint 1 has a female buckle 16, the rotating disk 6 is arranged between the step of the shell joint 1 and the upper end surface of the lower joint 9, and the conversion bearing 2 is respectively installed between the two ends of the rotating plate 6 and the shell joint 1, and the upper valve block, The lower valve block is respectively fixed in the annular cavity between the rotating disc 6 and the shell joint 1, the upper valve block and the lower valve block are respectively connected to a conversion bearing 2, and the annular cavity between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com