A Silicon Wafer Primary Negative Pressure Diffusion Process

A diffusion process and silicon wafer technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of cumbersome process manufacturing, diffusion of volatile phosphorus sources, and low diffusion efficiency, so as to improve diffusion efficiency and reduce back-to-source , The effect of simplifying the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

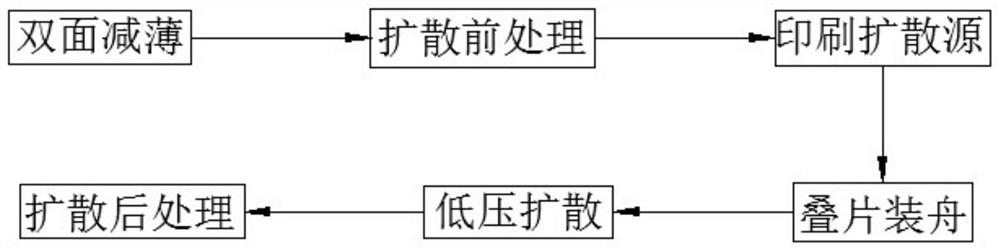

[0026] Such as figure 1 As shown, the present invention relates to a silicon chip negative pressure diffusion process, comprising the following steps:

[0027] 1) Double-sided thinning of the silicon wafer: use an etching solution to etch the silicon wafer on both sides to remove the surface damage layer, specifically including the following steps:

[0028] A. Use a thermometer to measure the temperature of the etching solution. The temperature is generally 0-15°C, and set the etching time of the silicon wafer according to the temperature of the etching solution. The etching time is generally 9-50s. Determine the etching time according to the temperature of the etching solution. Place in the etching solution for etching and thinning, and determine the thickness of the single-sided thinning of the silicon wafer according to the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com