Extraction device with suitable collector chamber

A collection cavity and chamber technology, applied in the system field of brewing devices, can solve the problems of simple structure and limited operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

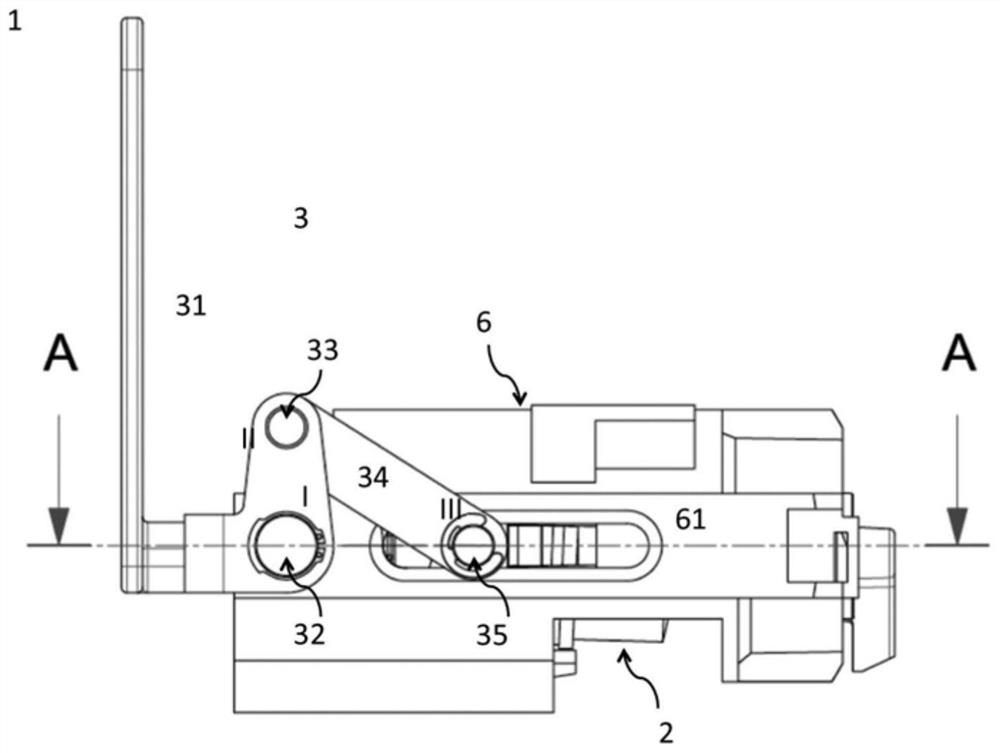

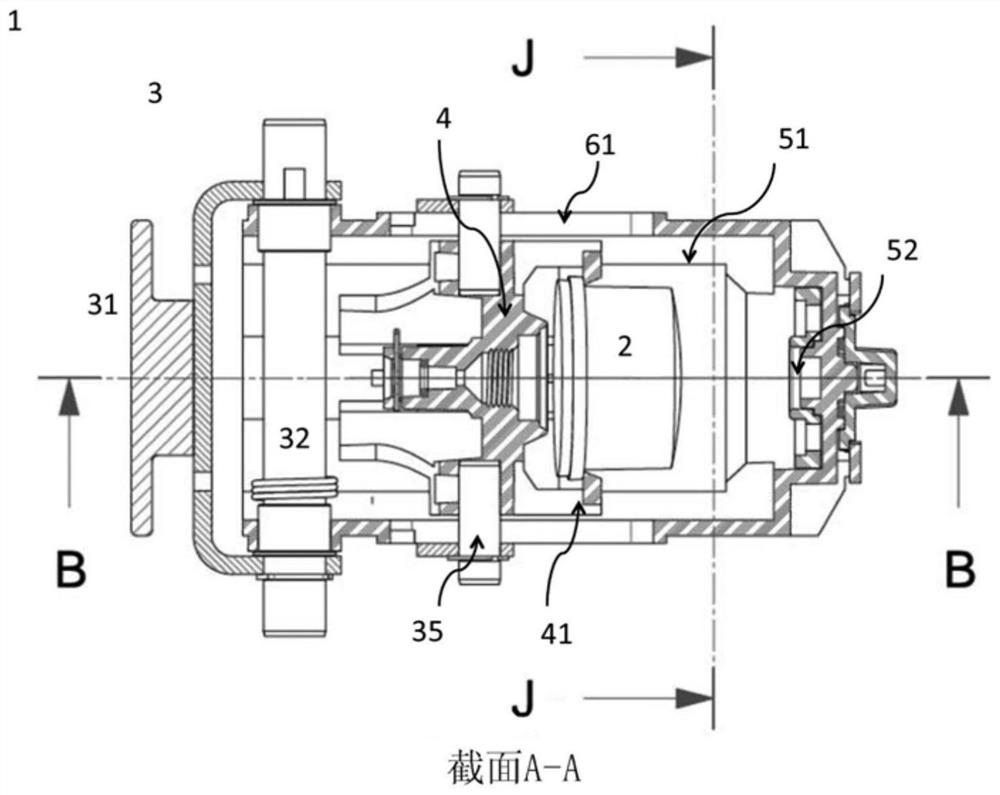

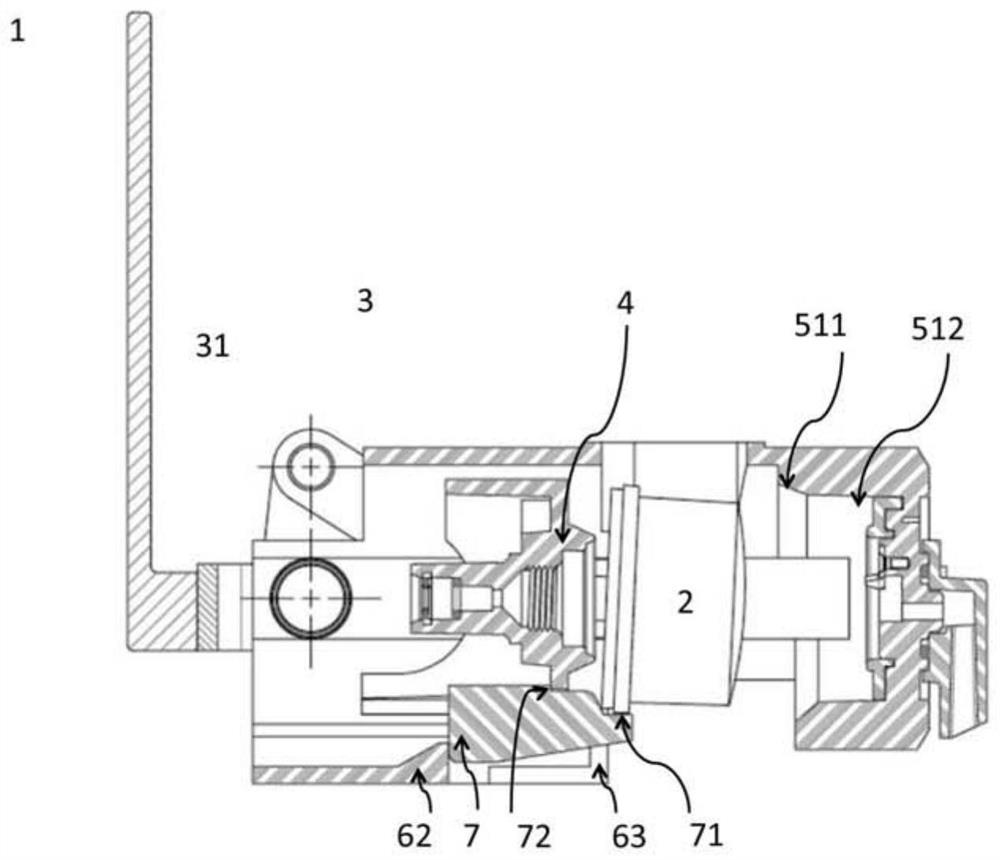

[0034] figure 1 A first embodiment of the brewing device ( 1 ) according to the invention is schematically represented.

[0035] The brewing device (1) has a force transmission device (3) adapted such that a rotational movement around the first axis of rotation (I) can be converted into an The open position corresponds to a translational movement of the longitudinal path between an upstream position and a downstream position of the brewing device (1) and vice versa.

[0036] The force transmission device (3) comprises a first actuating element (31) and a second actuating element (34), the first actuating element (31) being connected to a fixed shaft (32) arranged to be fixed associated so as to be rotatable about a first axis of rotation (I) and associated so as to be rotatable about a second axis of rotation (II) with a first connecting element (33) arranged to be movable, the second actuating element (34) by means of the Said first connecting element (33) is associated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com