Welded structure with excellent brittle crack propagation stop characteristics

A technology of brittle crack propagation and structural body, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of large safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] Hereinafter, the present invention will be described in detail based on examples.

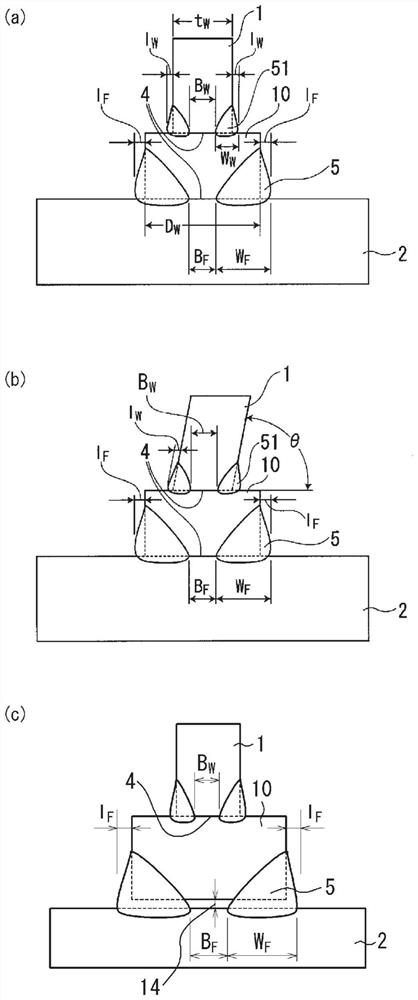

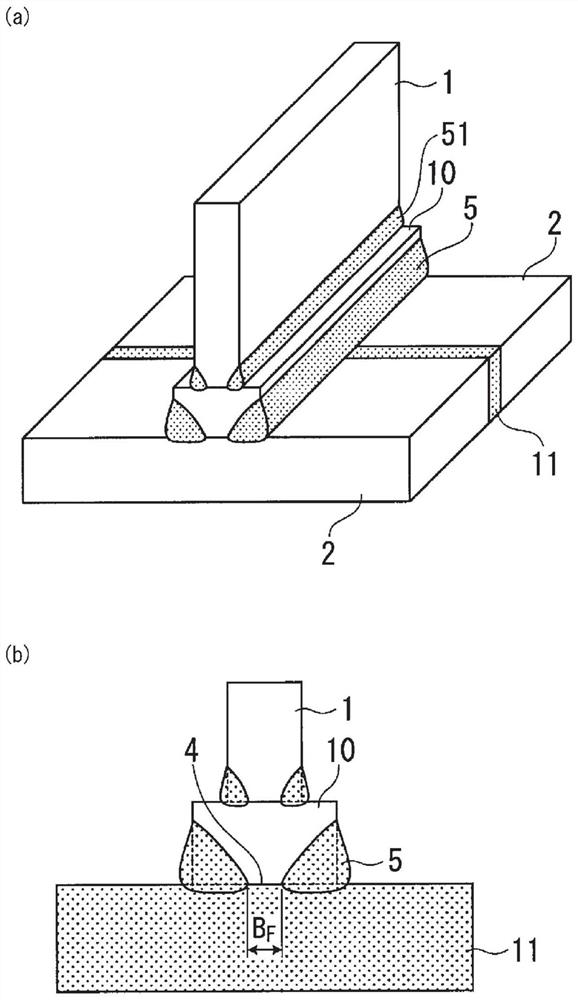

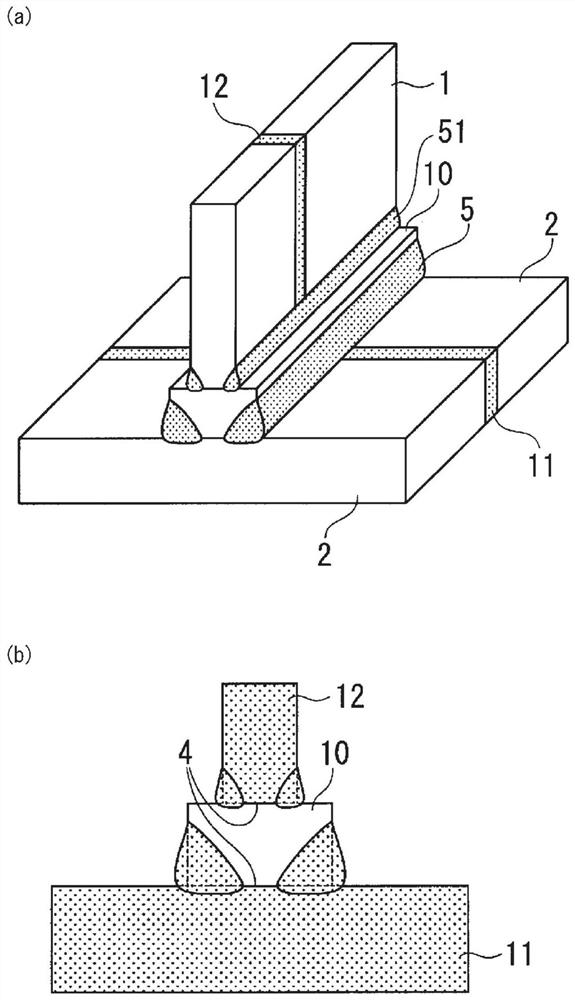

[0134] The thick steel plate with the plate thickness shown in Table 1-1 and Table 1-2 is used as the web and the flange, and the double member shown in Table 1-1 and Table 1-2 is provided at the butt joint between the web and the flange , produced Figure 4 (a), (b), (c) and Figure 5 (a), (b), (c) shown in the shape of the actual structural size of the large welded structural joints 9 . Figure 4 (a), (b), (c) assume the case of brittle crack initiation / propagation from the flange, Figure 5 (a), (b), (c) assume the case of brittle crack initiation / propagation from the web.

[0135] It should be noted that, in the fillet joint of the manufactured large-scale welded structural joint 9, the unwelded width B F , Double the plate width D of member 10 W , The leg length of the left and right fillet welds l F Change and change the ratio Y of the unwelded part to make figure 1 The unwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com