Atomizing device for oil tank cleaning and method for cleaning oil tank by using atomizing device

A technology for atomizing devices and oil tanks, which is applied to chemical instruments and methods, cleaning methods and appliances, spraying devices, etc., which can solve the problems of difficult and dangerous cleaning of oil tanks, achieve convenient cleaning work, and prevent dangerous accidents , the effect of inhibiting the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

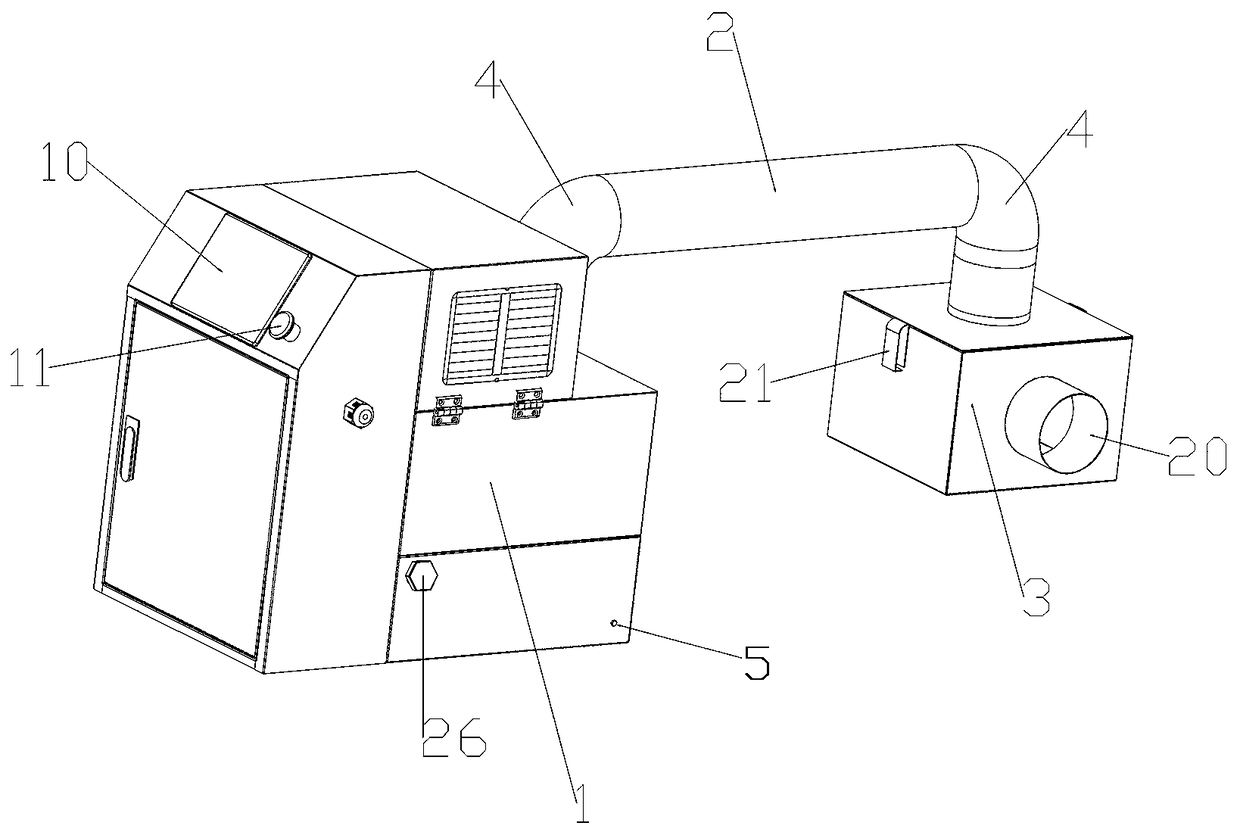

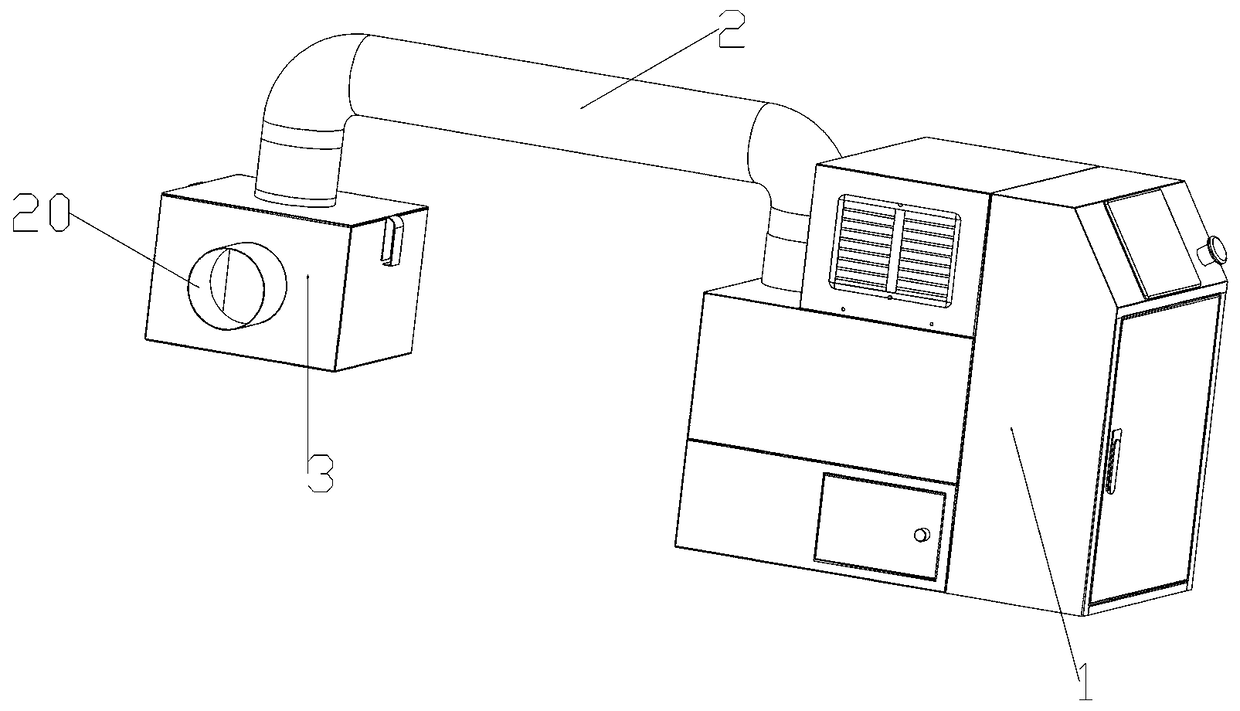

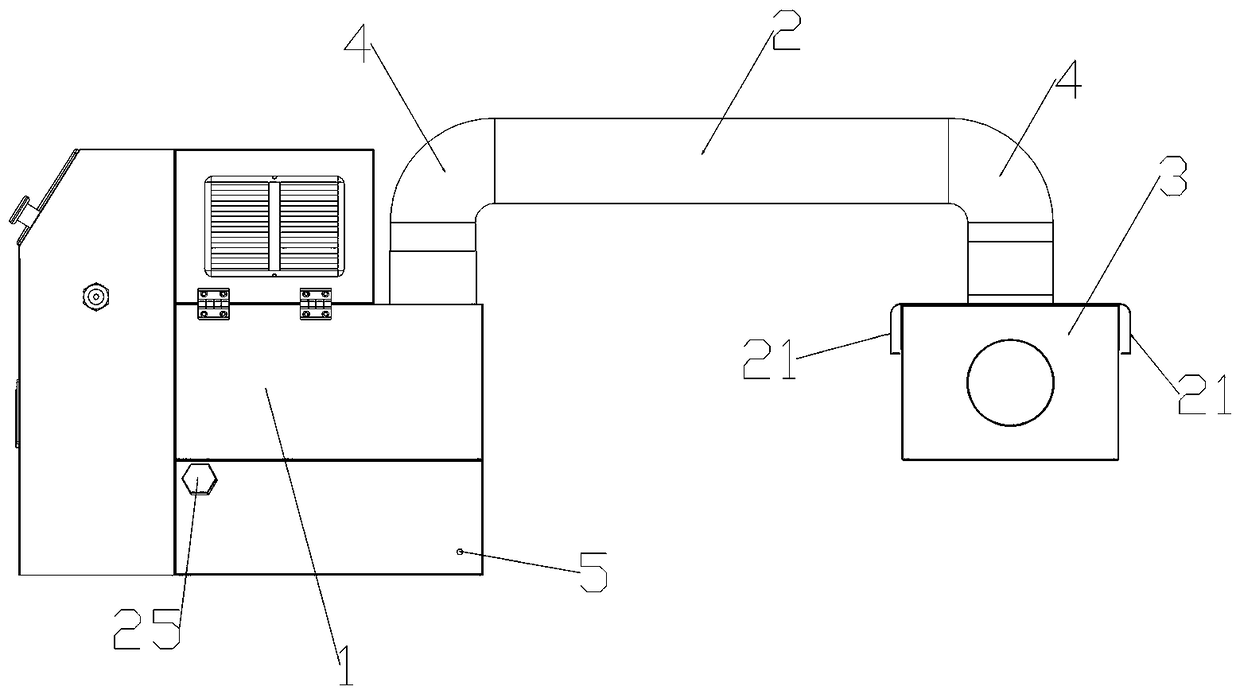

[0031] The first embodiment of the atomizing device for oil tank cleaning, such as Figure 1 to Figure 11 As shown, it includes an atomization host 1, an inhibitor delivery pipeline 2, and a mist collector 3. The atomization host 1 is used to atomize the inhibitor, and the inhibitor delivery pipeline 2 is used to communicate with the atomization host 1 and the oil tank to be cleaned. , The mist collector 3 is used to distribute the inhibitor so that the inhibitor can diffuse rapidly in the oil tank. The inhibitor conveying pipeline 2 includes a straight pipe and connecting hoses 4 arranged at both ends of the straight pipe. The connecting hose 4 can be a corrugated pipe, etc. The atomizing host 1 is provided with a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com