A cleaning device for tin ash in float glass tin bath

A technology of float glass and cleaning device, which is applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., and can solve problems such as glass surface threat, optical distortion, tin bath entry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

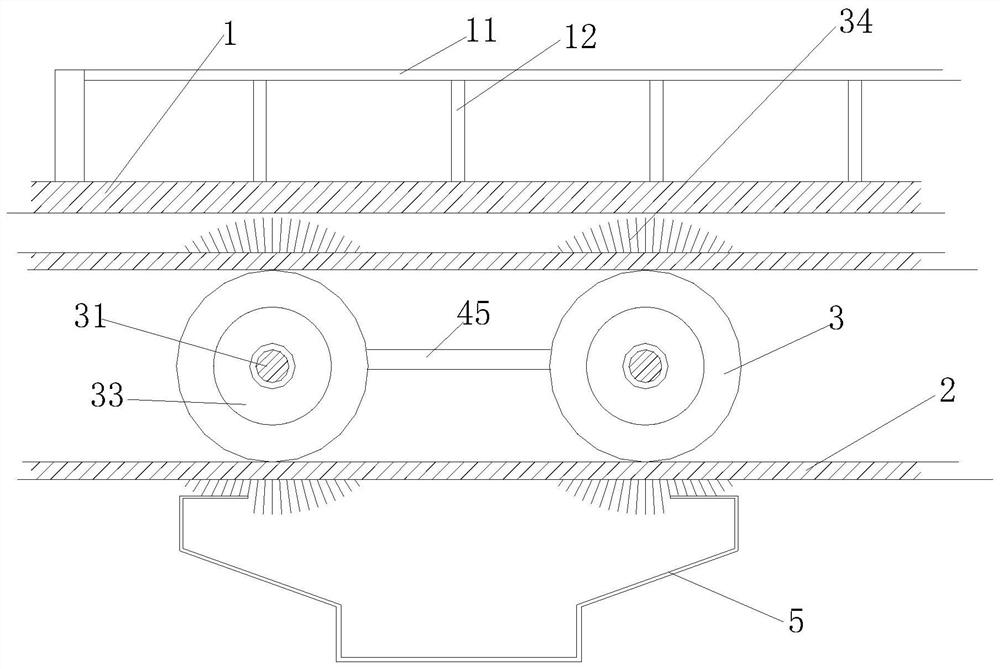

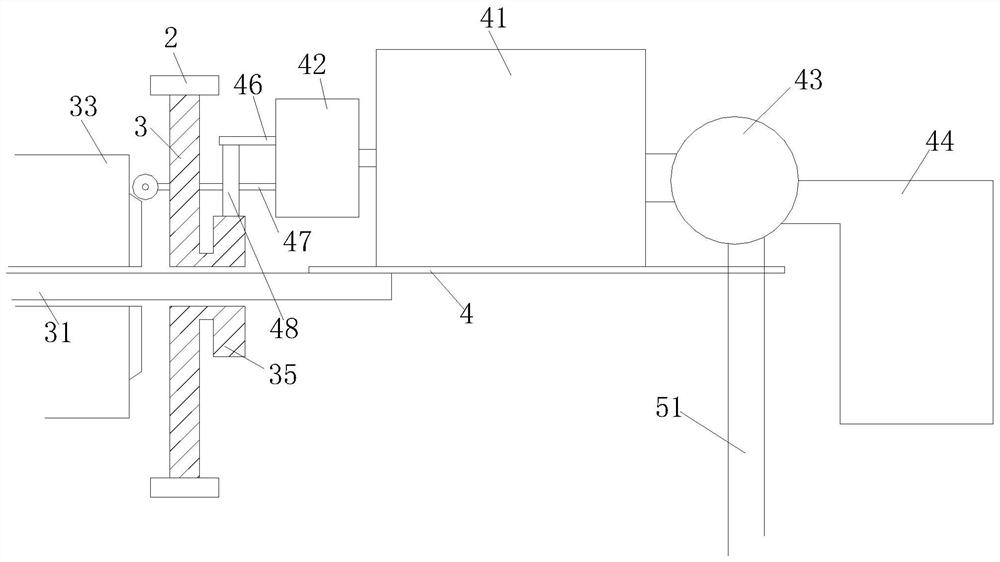

[0020] Such as figure 1 , figure 2 with image 3 Shown: a cleaning device for tin ash in a float glass tin bath, including a top cover 1, two slideways 2, four rollers 3, a platform 4 and an ash collecting funnel 5; the front of the two slideways 2, The rear is arranged side by side in parallel, and the four rollers 3 are engaged in two pairs on the front and rear slideways 2 respectively. Roller shafts 31 are arranged between the correspondingly arranged rollers 3 at the front and rear. The two roller shafts The same end of 31 extends outwards to form an extension end, the lower side of the platform 4 is welded to the outer extension ends of the two roller shafts 31 respectively, and the dust collection funnel 5 is located directly below the two roller shafts 31, so A motor 41 is installed on the platform 4, and a rotating cylinder 33 is sleeved on the two roller shafts 31. A rolling groove is arranged in the axial direction of the roller shaft 31, and the roller shaft 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com