A hot-bending forming method for laminated glass on a high-speed locomotive

A technology for high-speed locomotives and laminated glass, which is applied in glass forming, glass reshaping, and glass manufacturing equipment. It can solve problems such as complex process steps, poor optics, and optical distortion, so as to ensure optical quality, avoid optical distortion, Reduces the effect of direct thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The content of the present invention will be further described below in conjunction with the accompanying drawings.

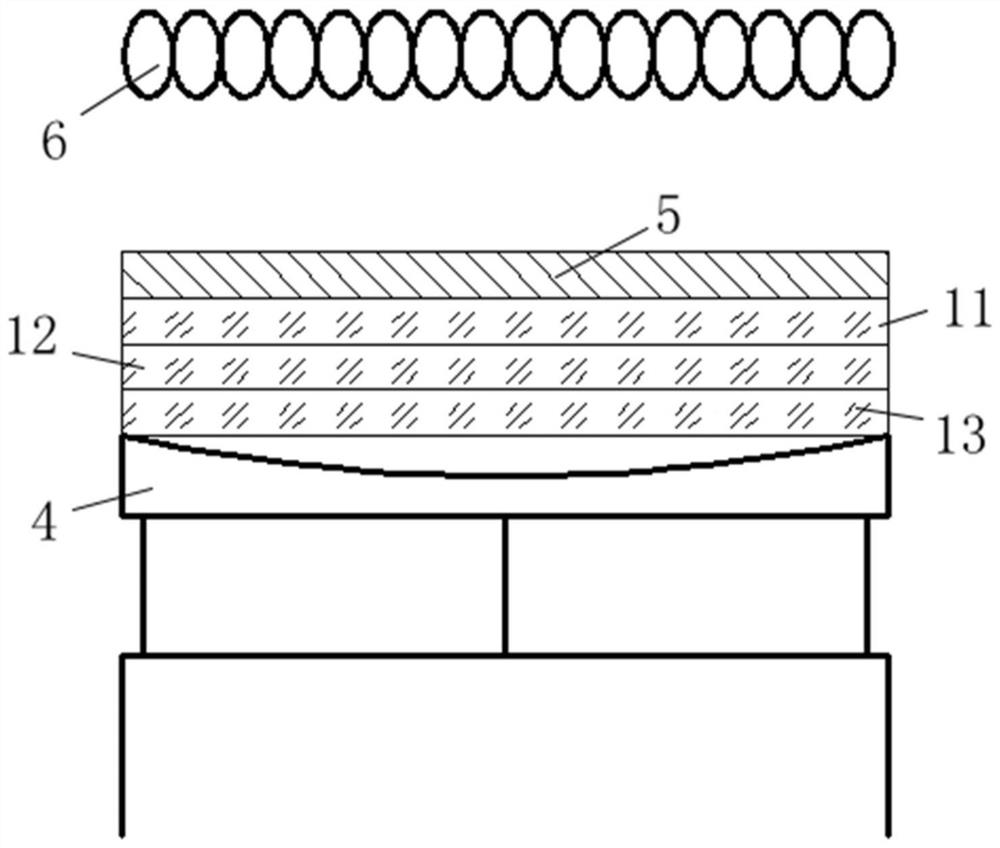

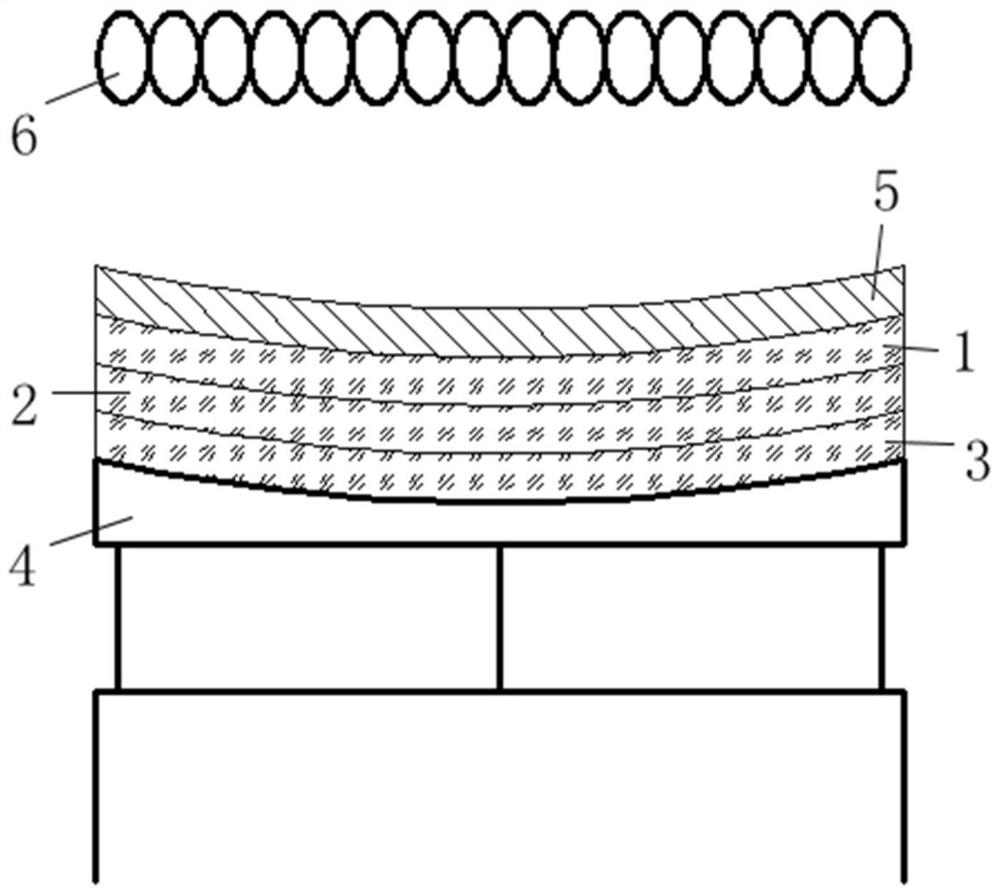

[0038] Such as figure 1 with figure 2 As shown, the laminated glass on the high-speed locomotive of the present invention includes at least two curved glass plates, a thermoplastic polymer film sandwiched between two adjacent curved glass plates, and at least one anti-splash film; figure 2 Although three curved glass plates are shown in the figure, i.e. the upper curved glass plate 1, the middle curved glass plate 2 and the lower curved glass plate 3, the figure 2 The laminated glass on the high-speed locomotive can be obtained through subsequent production of the three curved glass plates and the necessary amount of thermoplastic polymer film and anti-splash film, but it can be understood that the hot bending forming method described in the present invention can also be applied Laminated glass on a high-speed locomotive comprising two curved glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com