Crane lifting device

A lifting device and driving-type technology, which is applied in the direction of the crane, hoist, and traveling mechanism of the trolley, can solve the problems of difficult lifting, unsmooth lifting, and inability to easily dodge obstacles, etc., and achieves simple structure and low occupation The effect of small space and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

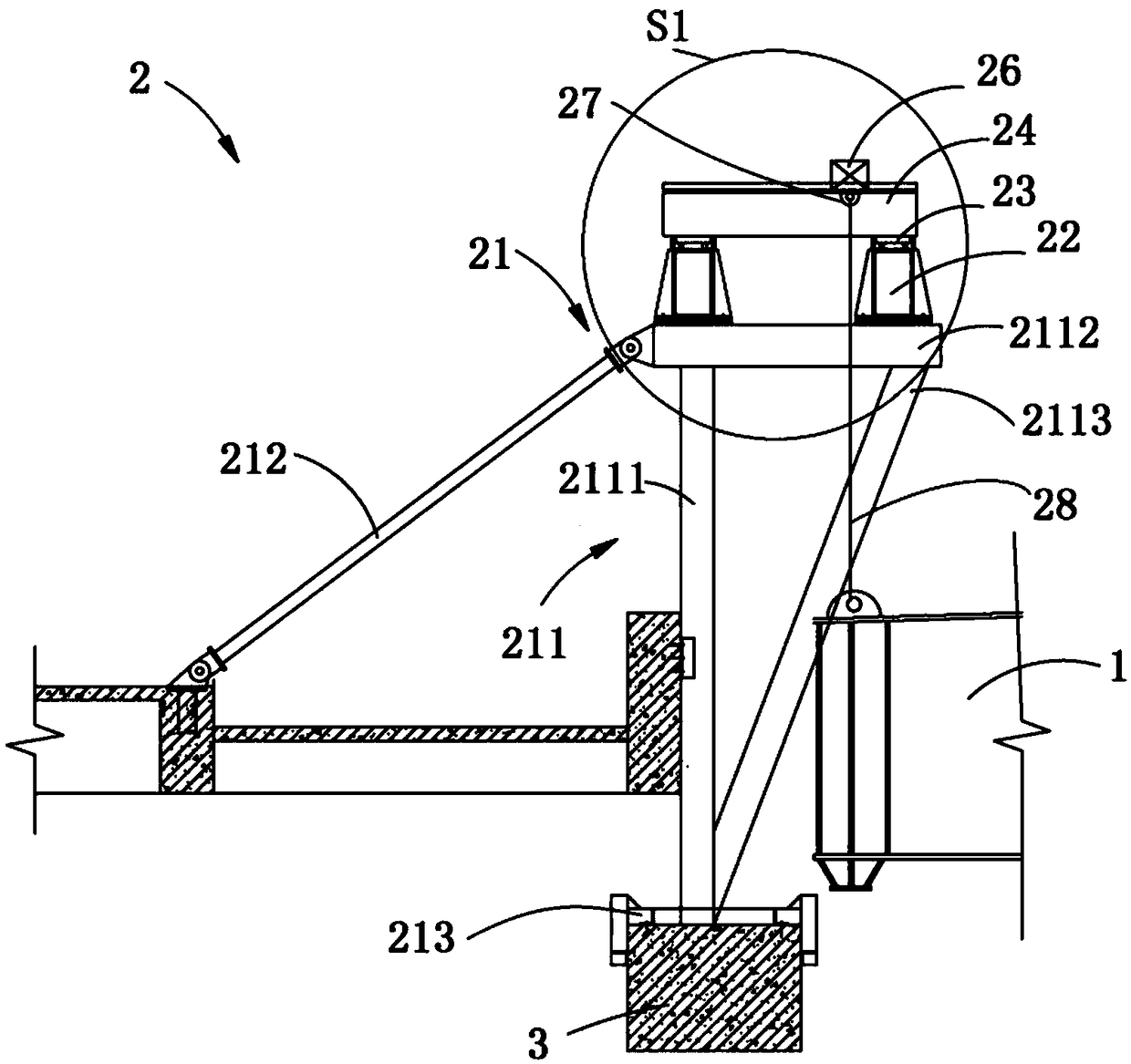

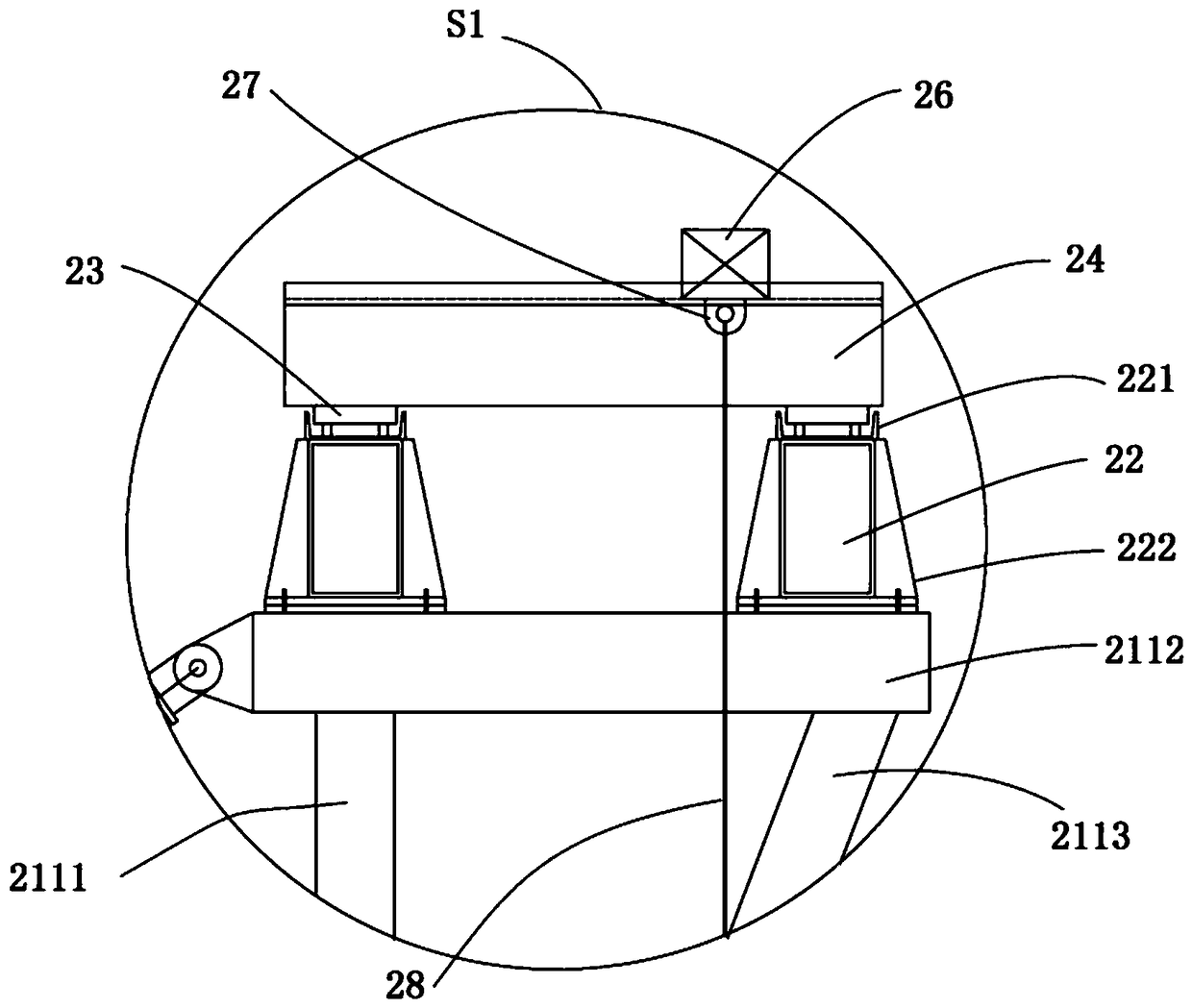

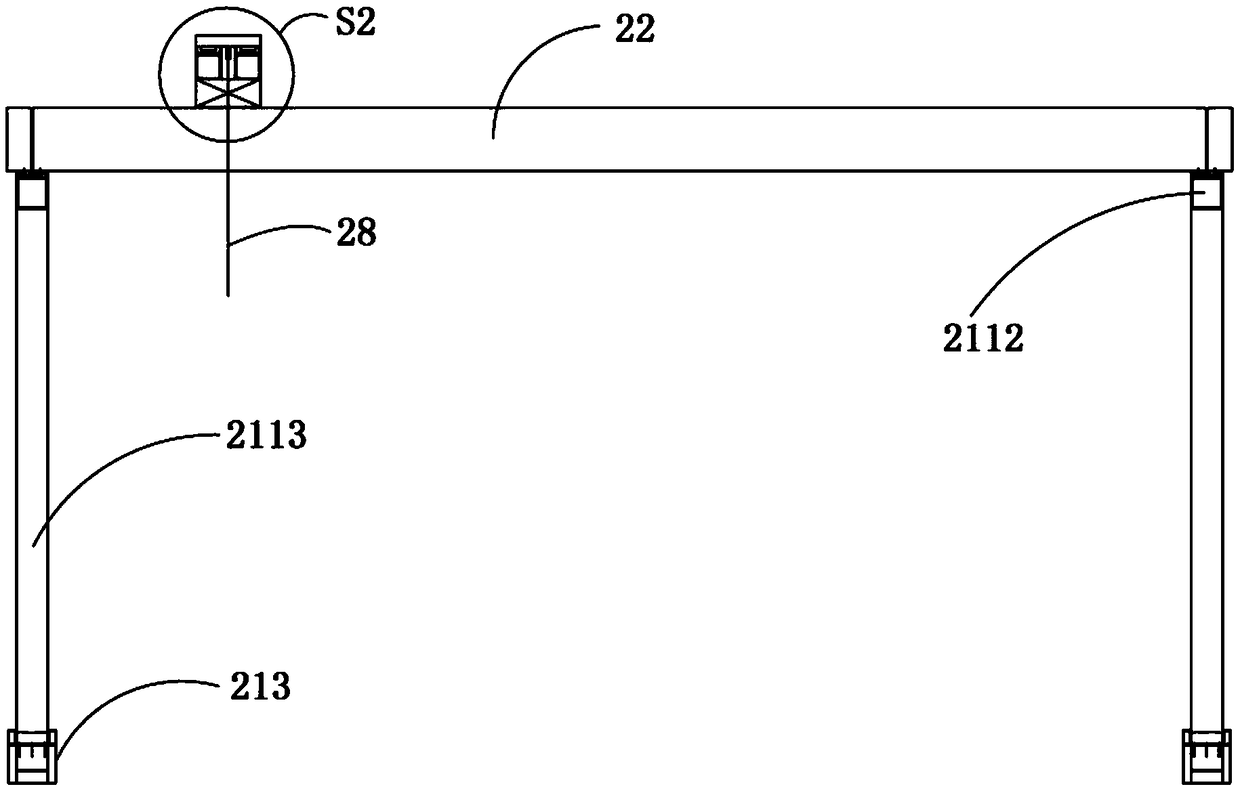

[0029] see Figure 1 to Figure 4 As shown, the present invention provides a driving-type lifting device for lifting a large-span hoisting object 1, the lifting device includes two sets of unit sections 2, and the two sets of unit sections 2 are respectively arranged on two structural beams 3 and extend along the length direction of each of the structural beams, the two structural beams 3 are arranged in parallel. In the embodiment of the present invention, the two structural beams 3 are respectively in the shape of a cuboid, and each group of the unit sections 2 includes a support seat 21, The walking longitudinal beam 22, the longitudinal traveling trolley 23, the traveling beam 24, the lateral traveling trolley 25, the connecting beam 26 and the electric hoist (not shown) arranged on the support base 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com