Warehouse logistic handling device

A technology for loading and unloading devices, warehousing and logistics, applied in the direction of lifting devices, etc., can solve problems such as hidden dangers of cargo dumping, unadjustable fork spacing, unstable center of gravity of pallets, etc., to eliminate hidden dangers and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

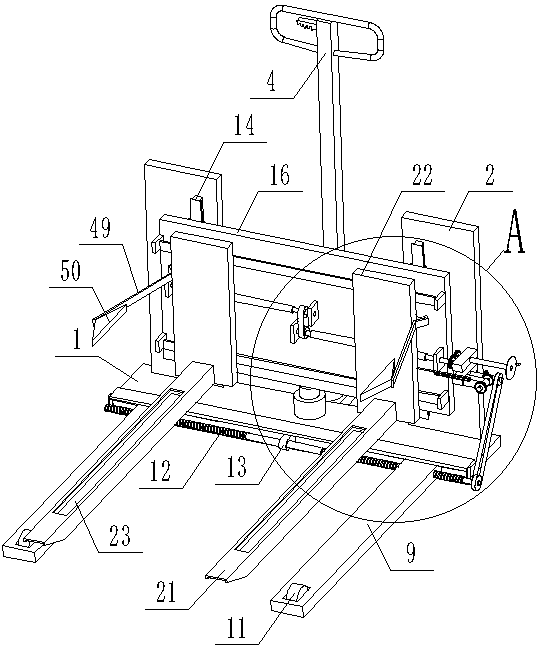

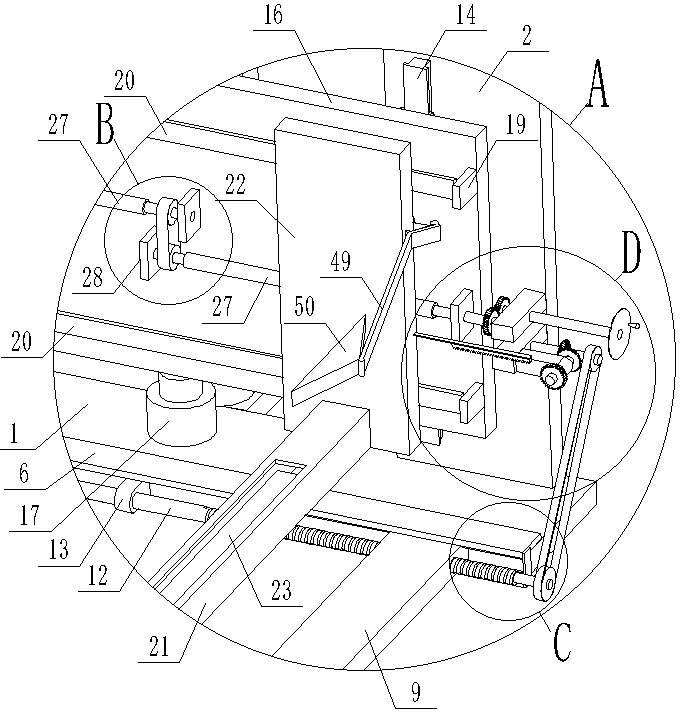

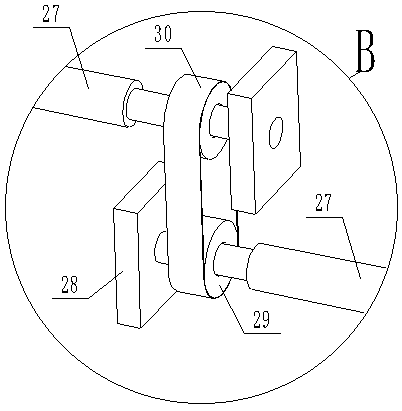

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-13 As shown, a warehouse logistics loading and unloading device includes a base 1, a universal wheel 3, a handle 4, a manual hydraulic vehicle oil pump 5, a leg 9, a bottom wheel 11 and a lifting cylinder 17, the handle 4 and the manual hydraulic vehicle oil pump 5 is connected, and the manual hydraulic vehicle oil pump 5 supplies oil to the lifting cylinder 17; a backboard 2 is fixed on the top of the base 1, and the universal wheel 3 is installed on the backboard 2, and the end of the backboard 2 away from the universal wheel 3 is fixed with a Slide rail 14, slide rail 14 is installed in slide rail baffle plate 15, and slide rail baffle plate 15 is fixed on the mounting plate 16, and the bottom end of mounting plate 16 is provided with lifting oil cylinder 17, and lifting oil cylinder 17 is fixed on the bottom of base 1. Top; a baffle plate 19 is fixed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com