Bucket archconnecting piecesfor H-shaped steel building

A technology of connectors and H-shaped steel, which is applied in the direction of construction and building construction, and can solve the problems of low guarantee coefficient of solder joints and poor rigidity of the overall building.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

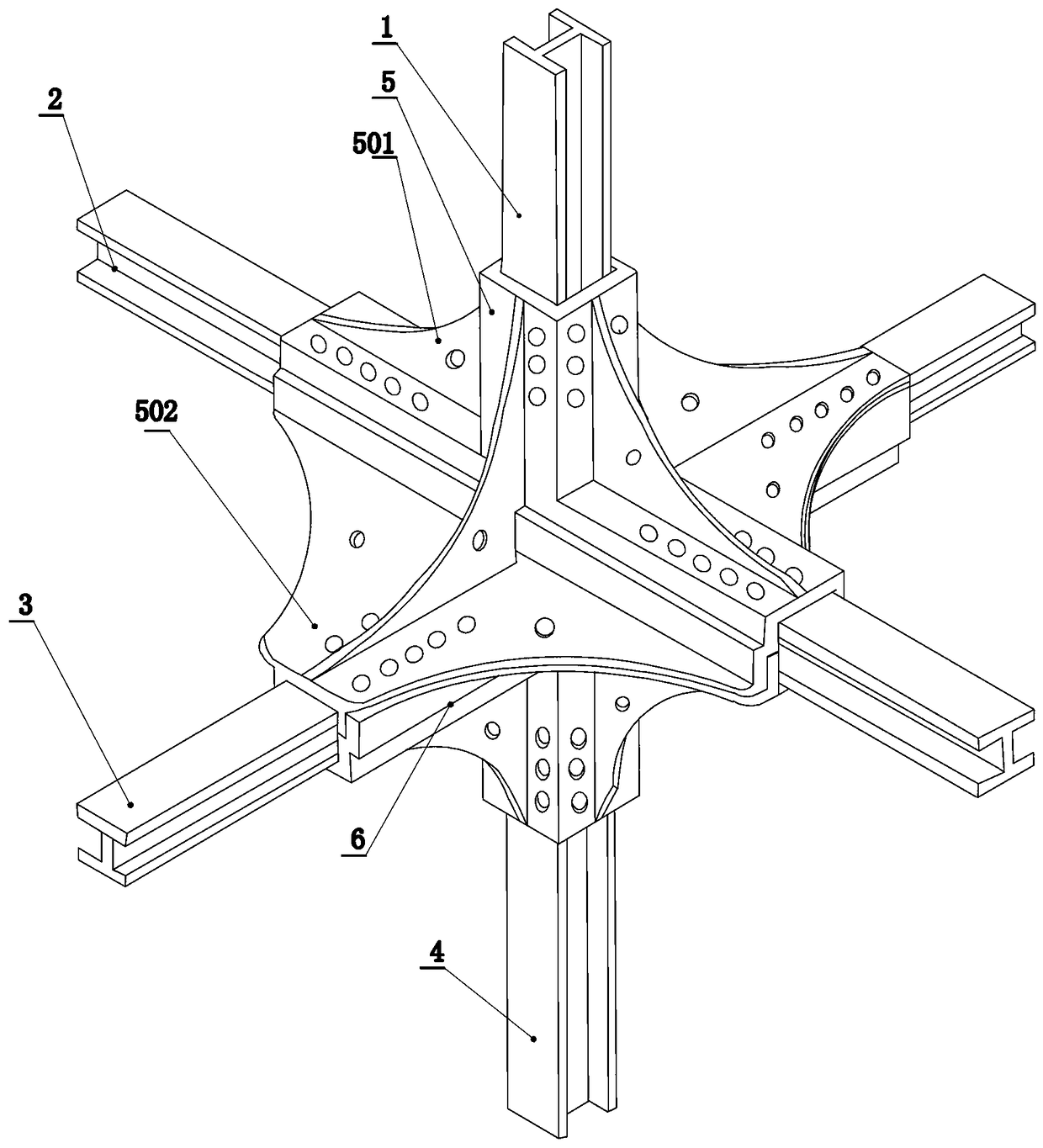

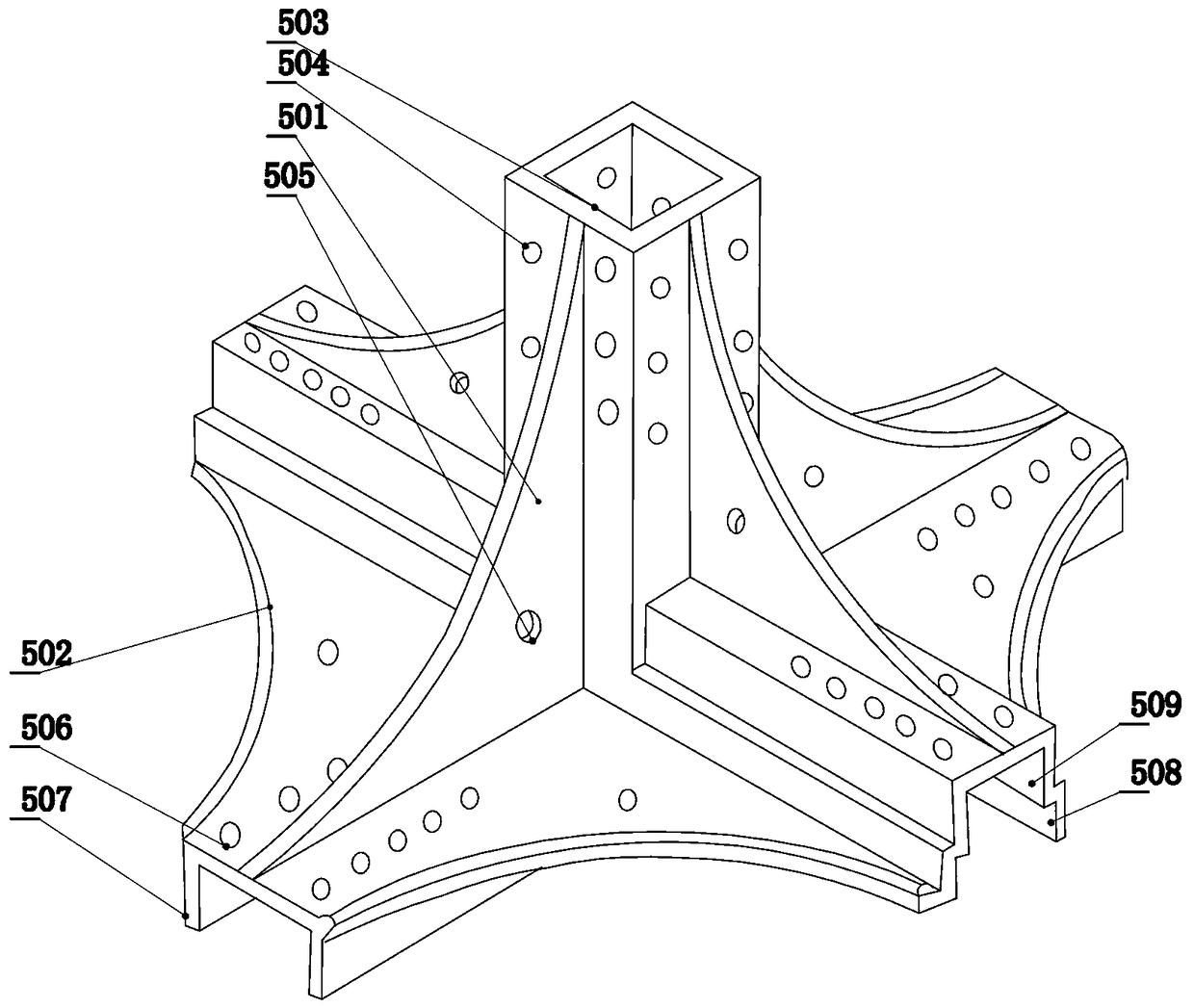

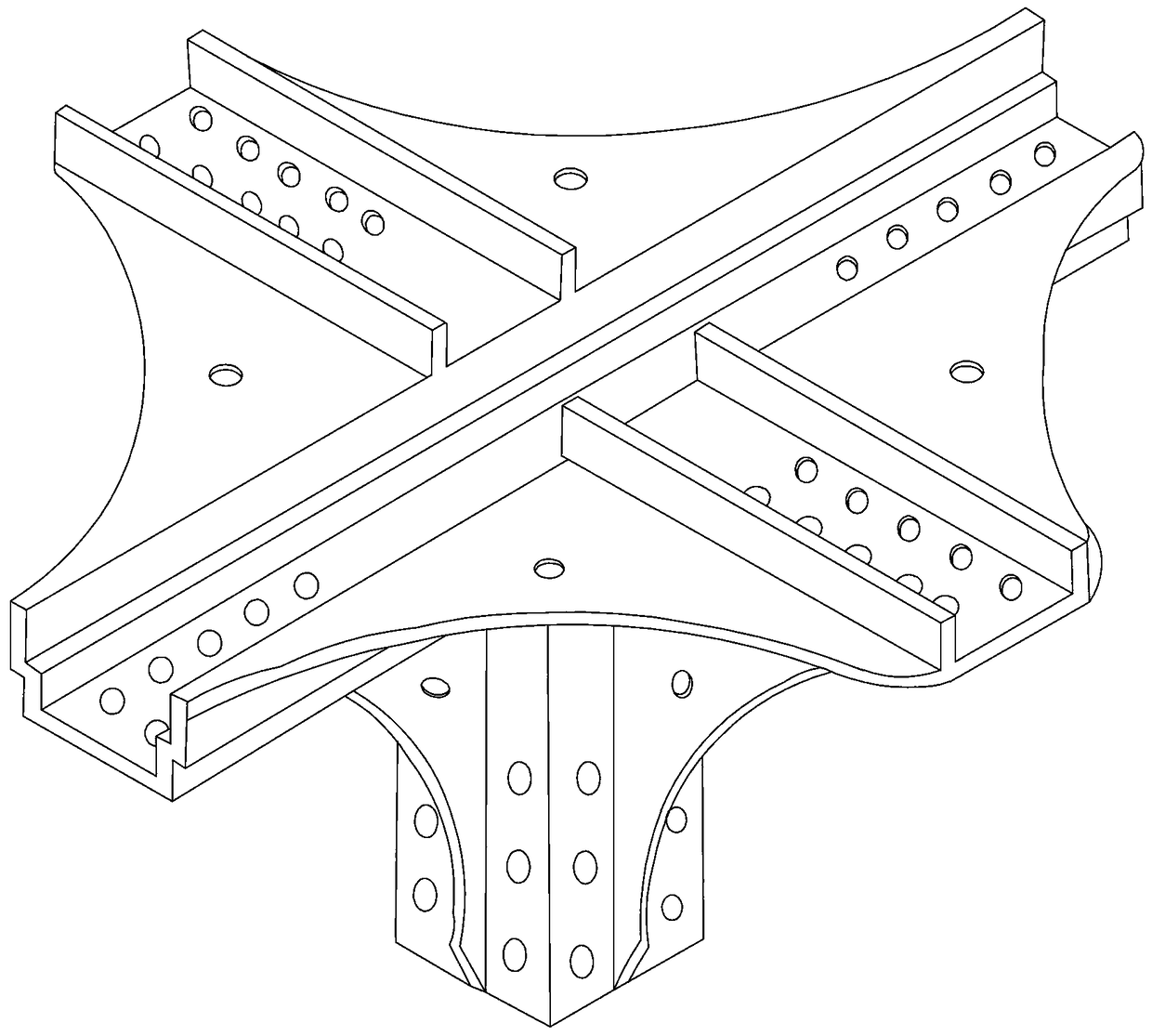

[0029] The H-shaped steel building adopts H-shaped steel as the main frame structure, and is designed in the way of top beams and columns. It adopts the traditional Chinese four beams and eight columns, bucket arches, and tenon riveting as the main features. The frame has no welding points, and the beams and columns have no welds. Hold the beam and column, and then fix the beam-column and bucket arch connectors through bolts. Beams and columns are mainly responsible for the load-bearing force of the building, while bucket arch connectors are mainly responsible for external strong forces, namely leverage force, shear force and wave shock force. Therefore, the bucket arch connector is the main guarantee against strong earthquakes.

[0030] figure 1 For the convenience of expression, no connecting bolts or pins are drawn. like figure 1 As shown, the top of the column of the steel structure is located under the girder 3, the sub-beam 2 is installed on the girder in a "cross" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com