Tobacco picking device and method

A technology of tomato and driving device, applied in agricultural machinery and implements, applications, harvesters, etc., can solve the problems of low picking efficiency, tomato damage, and high labor intensity of workers, shorten picking steps, avoid walking back and forth, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

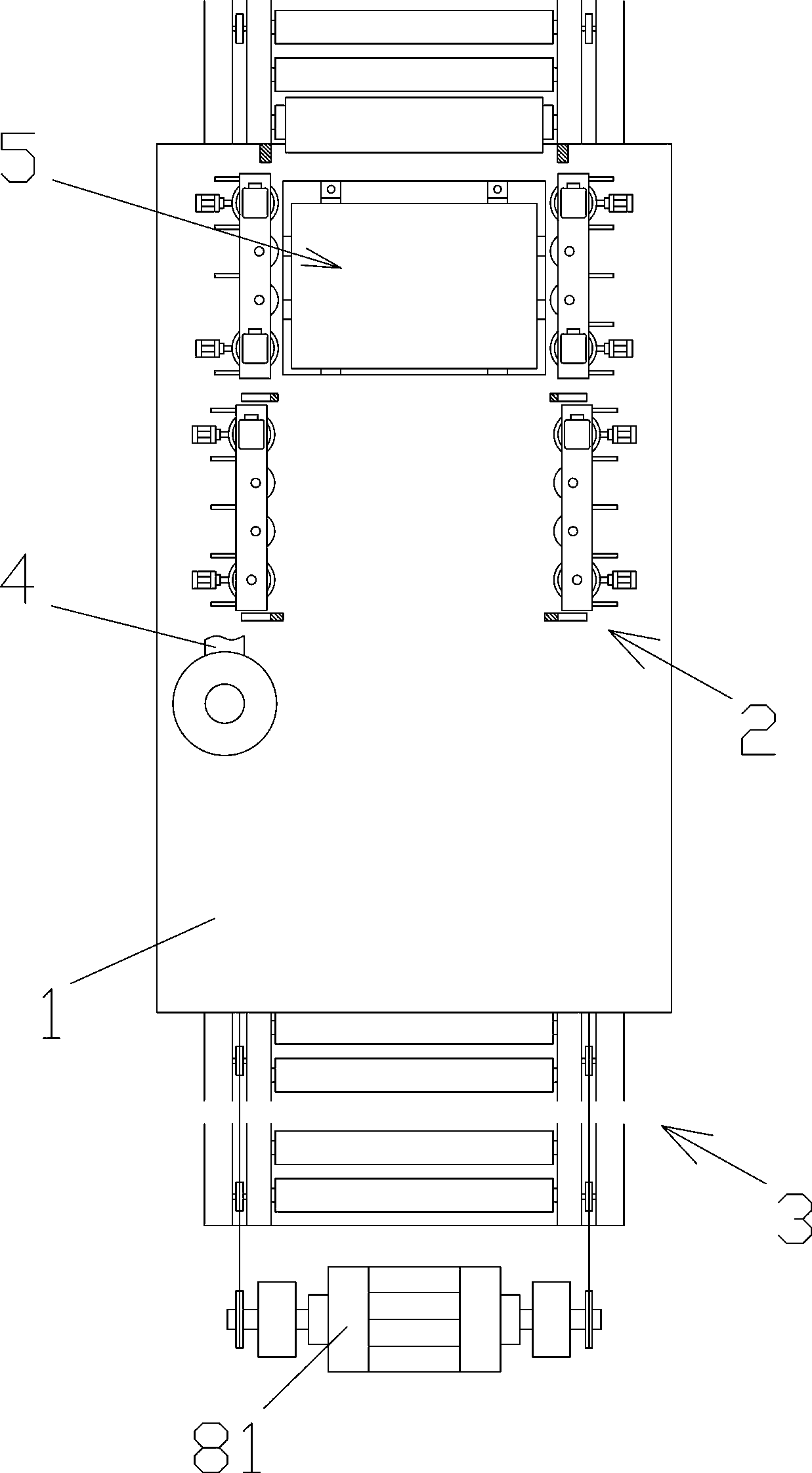

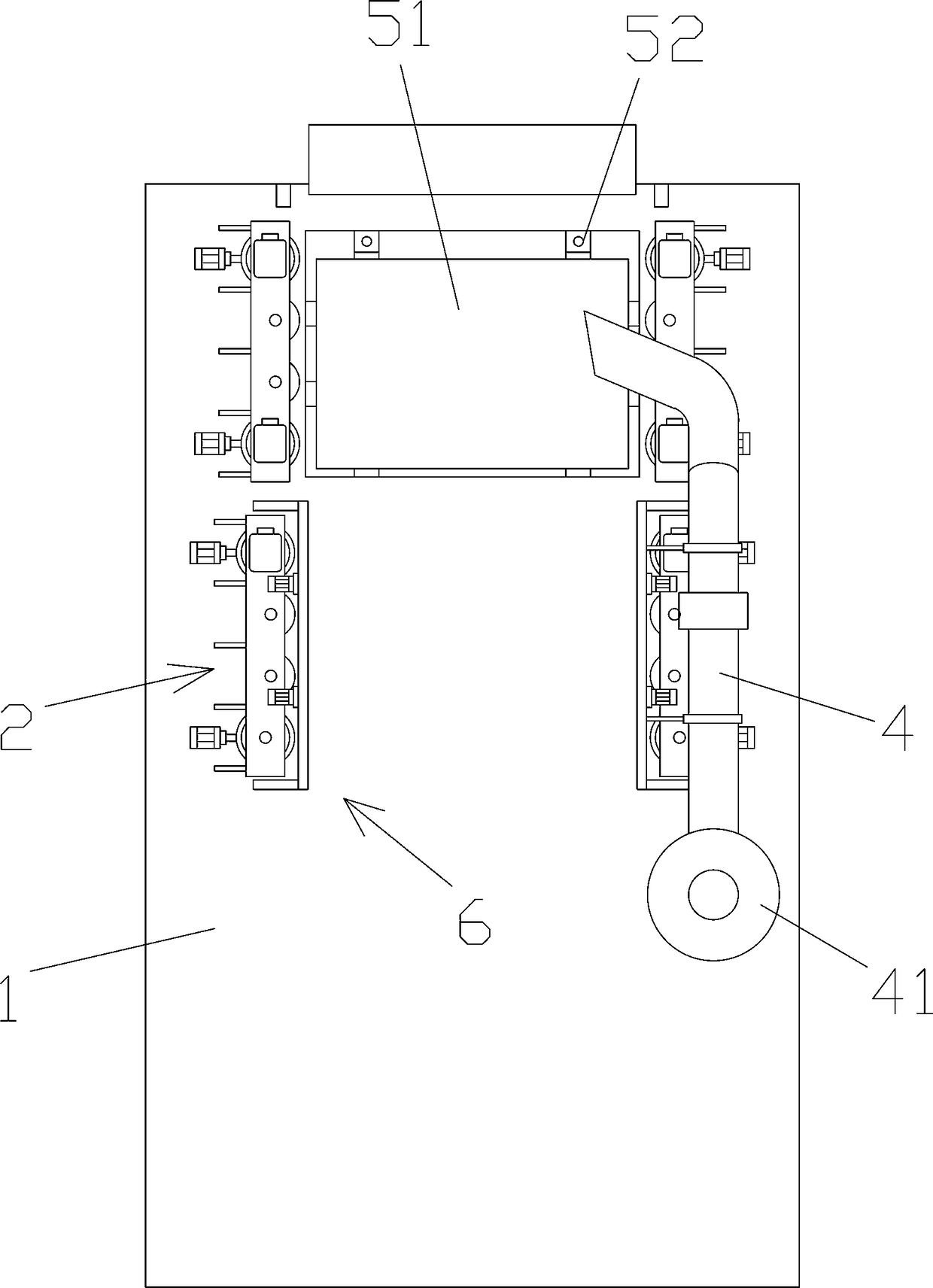

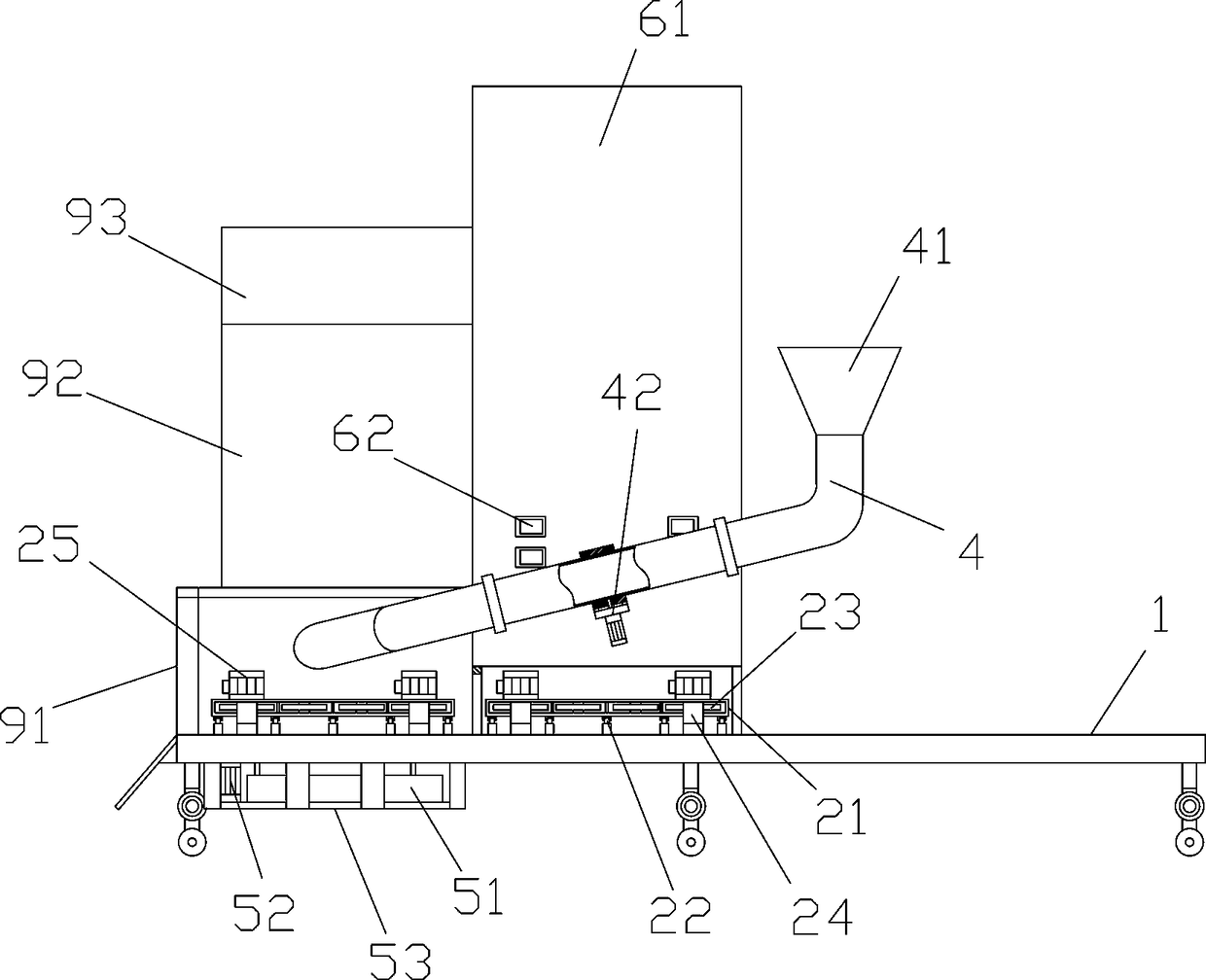

[0039] Such as Figures 1 to 11 As shown, a tomato picking device includes a driving device 3 and a trailer 1, and the driving device 3 drives the trailer 1 to walk between two ridges of tomato plants, and the trailer 1 is provided with a disk storage device 6, a disk drive device and a weighing device 5;

[0040] Such as Figure 4 and 9 As shown, the disk storage device 6: comprises two vertical plates 61 fixedly connected vertically on the trailer 1, a group of plate-loading mechanisms are respectively arranged on the two vertical plates 61, and a Opening 63, a plurality of pallets 7 are stacked between two vertical plates 61;

[0041] Such as Figures 1 to 3 As shown, there are multiple groups of disk drive devices, and each group of disk drive devices is arranged in sequence along the traveling direction of the trailer 1. Each group of disk drive devices is composed of two disk drive parts 2 arranged in parallel at intervals. Each group of disk drive devices The two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com