A transmission process of supercritical carbon dioxide

A carbon dioxide and supercritical technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of stable fluid properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

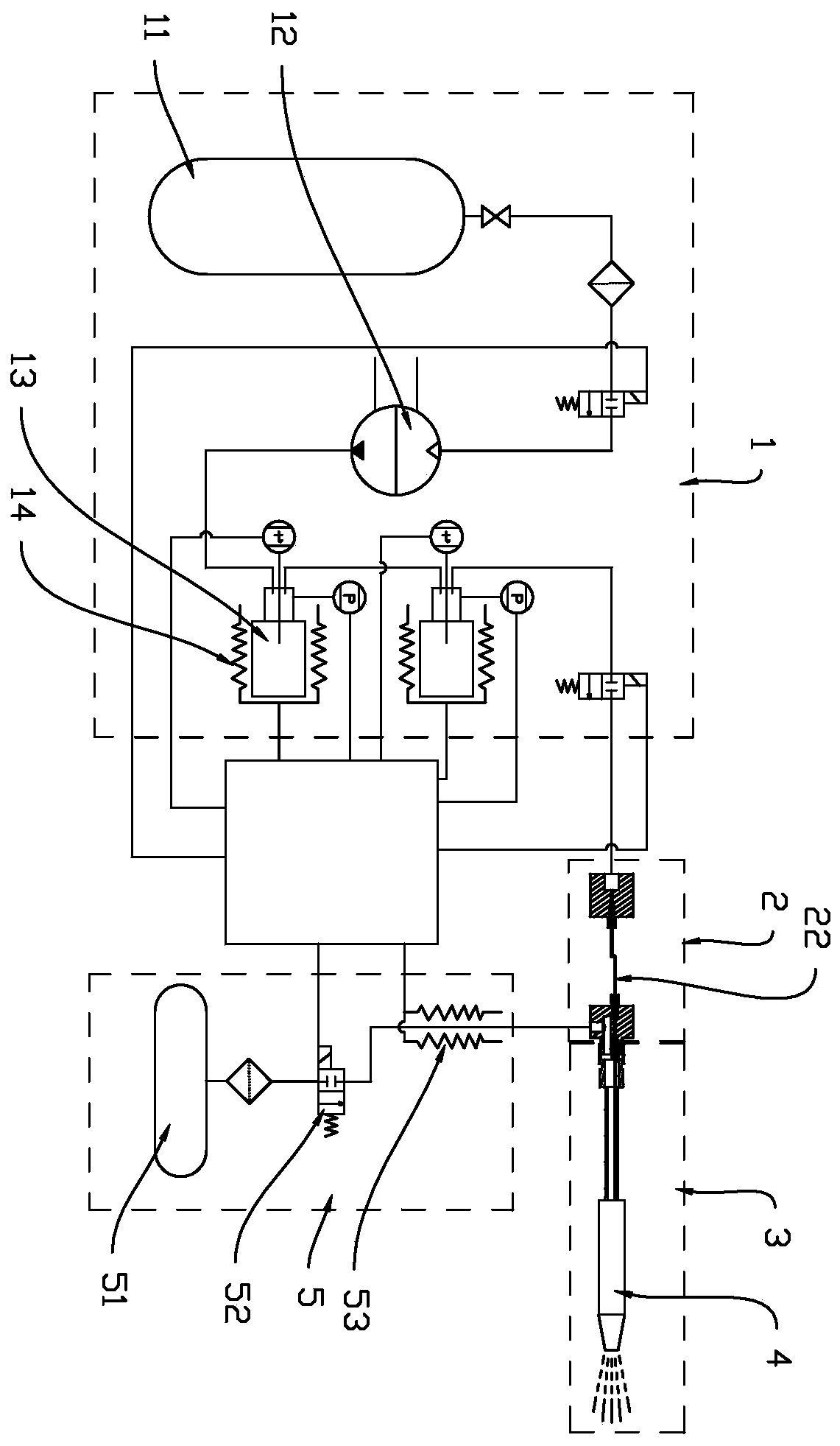

[0027] refer to Figure 1 ~ Figure 4 , the present invention is a kind of transmission technology of supercritical carbon dioxide, comprises the following steps:

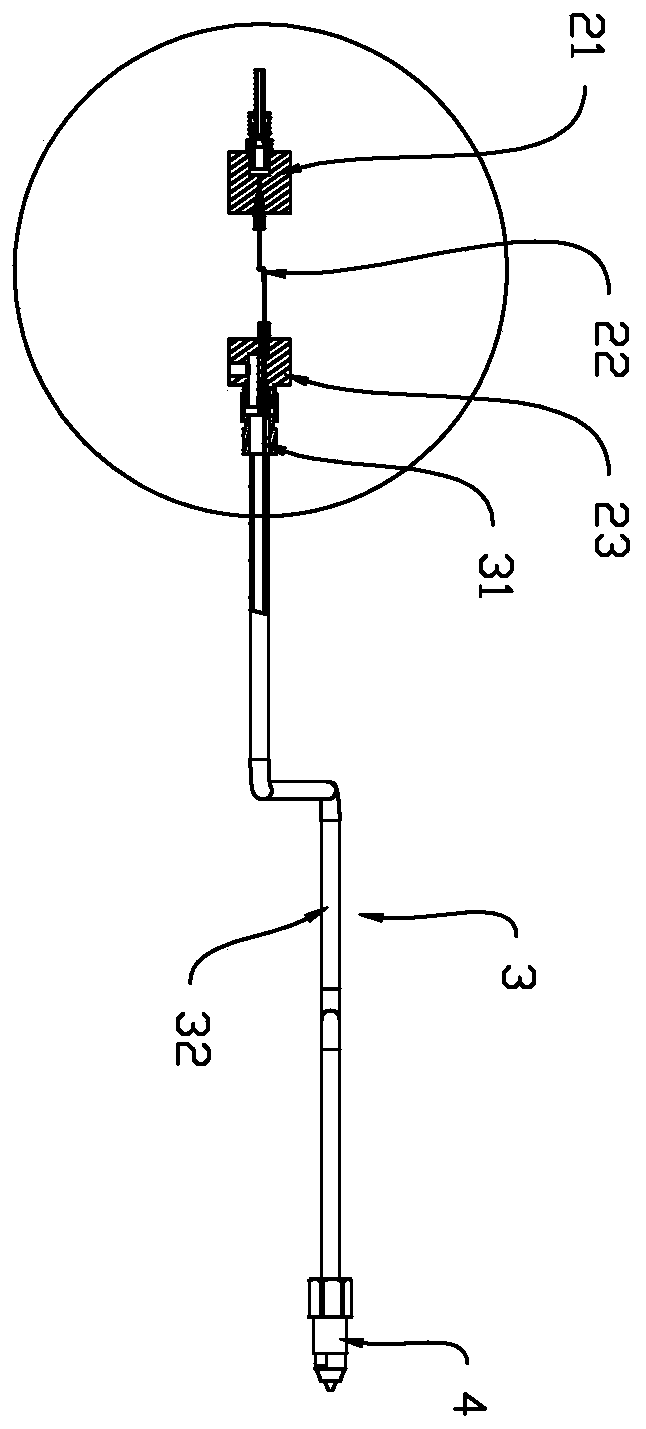

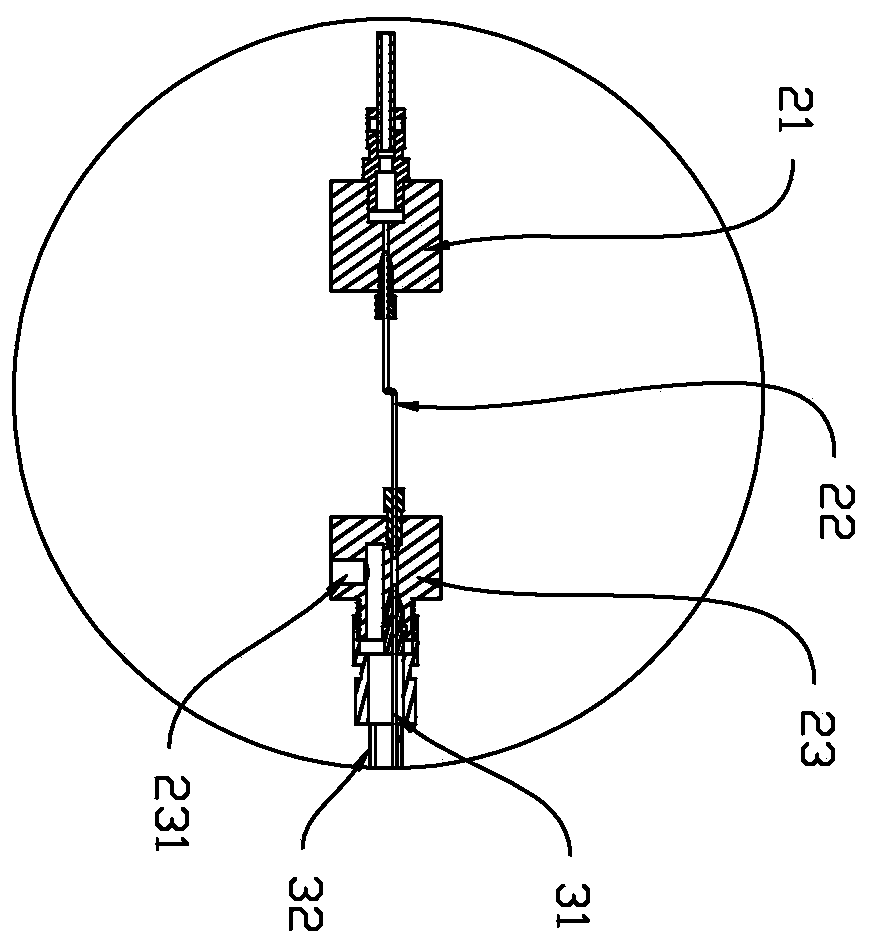

[0028] 1) A supercritical carbon dioxide flow regulating device 2 is arranged between the supercritical carbon dioxide generating device 1 and the supercritical carbon dioxide output device 3, and the transfer pipeline 22 in the supercritical carbon dioxide flow regulating device 2 is replaced until it meets the output requirement, mainly By switching the length of the transfer pipeline 22, to change its flow rate;

[0029] 2) generate supercritical carbon dioxide by supercritical carbon dioxide generating device 1, and supercritical carbon dioxide flows into the output pipeline 31 of supercritical carbon dioxide output device 3 through supercritical carbon dioxide flow regulating device 2;

[0030] 3) An auxiliary gas flow pipeline 32 is provided outside the output pipeline 31 of the supercritical carbon dioxide o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com