Production method for glass bottle

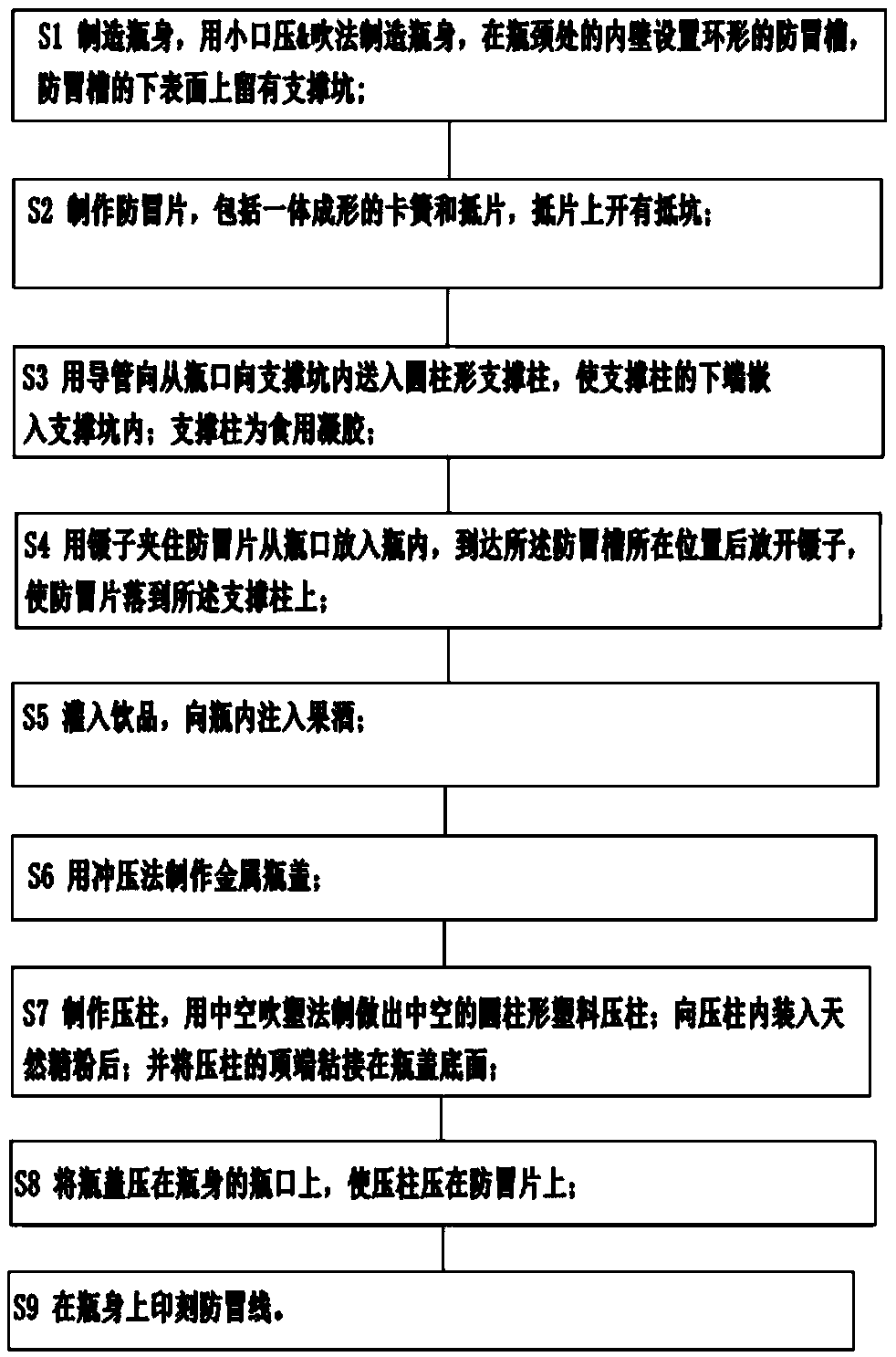

A production method and technology for glass bottles, applied in bottling machines, bottle filling, synchronization devices, etc., can solve problems such as scratching consumers and potential safety hazards, and achieve the effect of avoiding potential safety hazards and preventing speculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

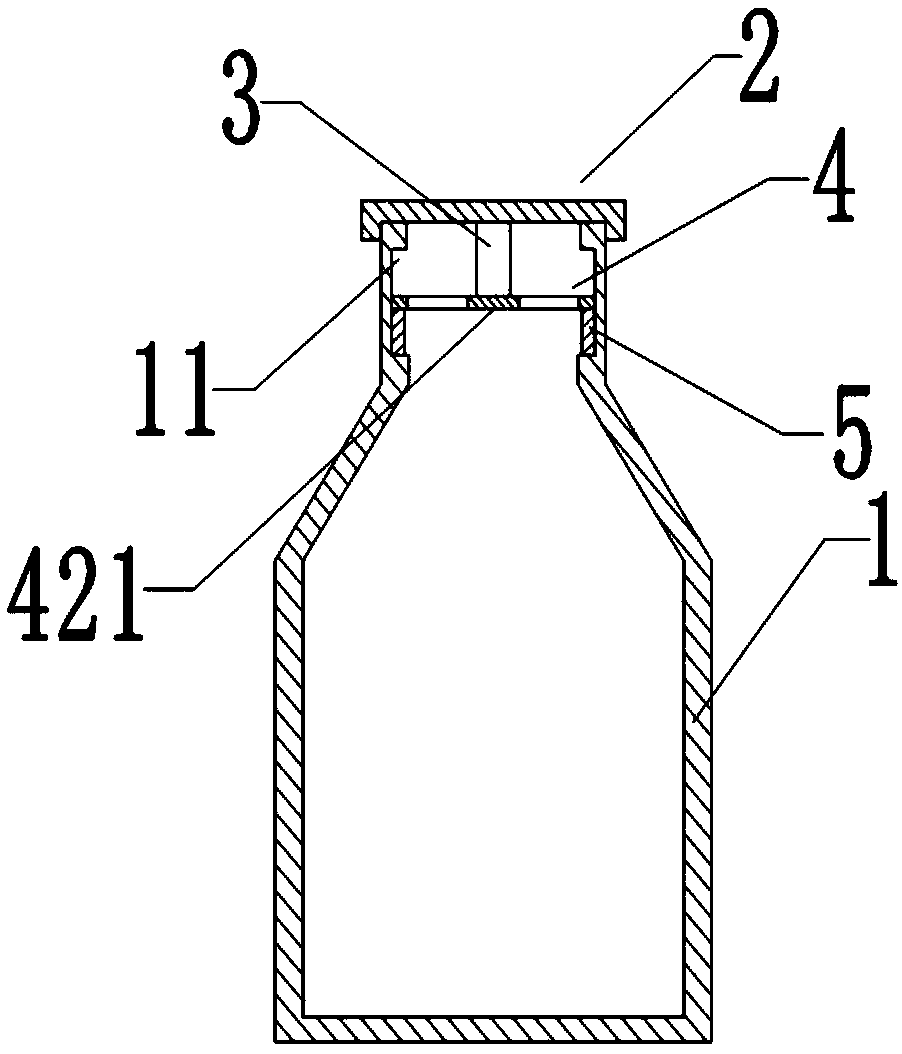

[0064] The difference from Example 1 is:

[0065] In S1, there is a groove on the inner bottom surface of the bottle body, and the cross section of the groove is a regular pentagon;

[0066] In S2, there is no pit on the counter-pit of the anti-counterfeiting sheet, but a cylindrical center hole is set at the position of the pit;

[0067] In S7, the cross-sectional diameter of the pressure column is four millimeters smaller than the cross-sectional diameter of the central hole, and the cross-sectional shape of the bottom of the pressure column is a regular pentagon, and the area is equal to the cross-sectional area of the groove; the body of the pressure column is integrally formed with a pressure block , the cross section of the compact is triangular;

[0068] In S8, the pressure column passes through the central hole, and the bottom end of the pressure column is embedded in the groove on the inner bottom surface of the bottle body; the pressure block is pressed on the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com