Novel wooden extrusion wedge

A new type of plate-body technology, applied in the direction of bolts, etc., can solve the problems of inability to completely seal, waste materials, and different extrusion degrees, and achieve the effect of simple structure, reasonable design and uniform extrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention will not be limited.

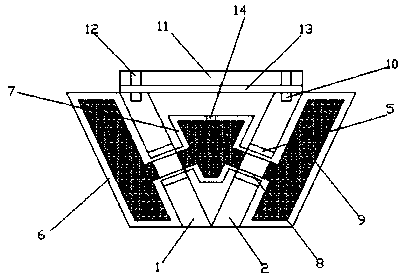

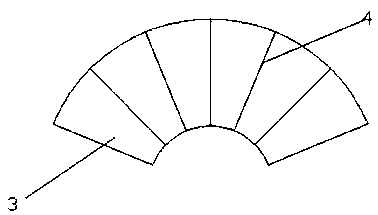

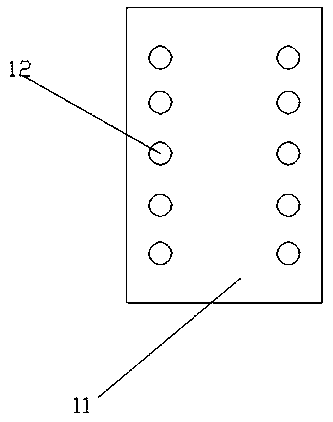

[0017] Such as Figure 1 to Figure 3 As shown, a new type of wooden extrusion wedge includes a left plate body 1 and a right plate body 2, the left plate body 1 and the right plate body 2 are hinged to form a hinge, and the left plate body 1 and the right plate body 2 A fan-shaped connecting piece 3 is provided between the two vertical ends perpendicular to the hinged end, and the fan-shaped connecting piece 3 is provided with a folding indentation 4, and the left plate body 1 and the right plate body 2 are provided with a bar-shaped opening 5 , the outer surface of the left plate body 1 and the right plate body 2 is fitted with an outer expansion pad 6 with a cavity, and an inner expansion pad 7 with a cavity is placed between the left plate body 1 and the right plate body ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap