Testing Device for Supporting Plate of Automobile Accessories

A technology for testing equipment and auto parts, used in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of time-consuming and labor-intensive, difficult to accurately detect products, low detection accuracy, etc., to avoid manual operation. , Guarantee the accuracy, the effect of ensuring the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

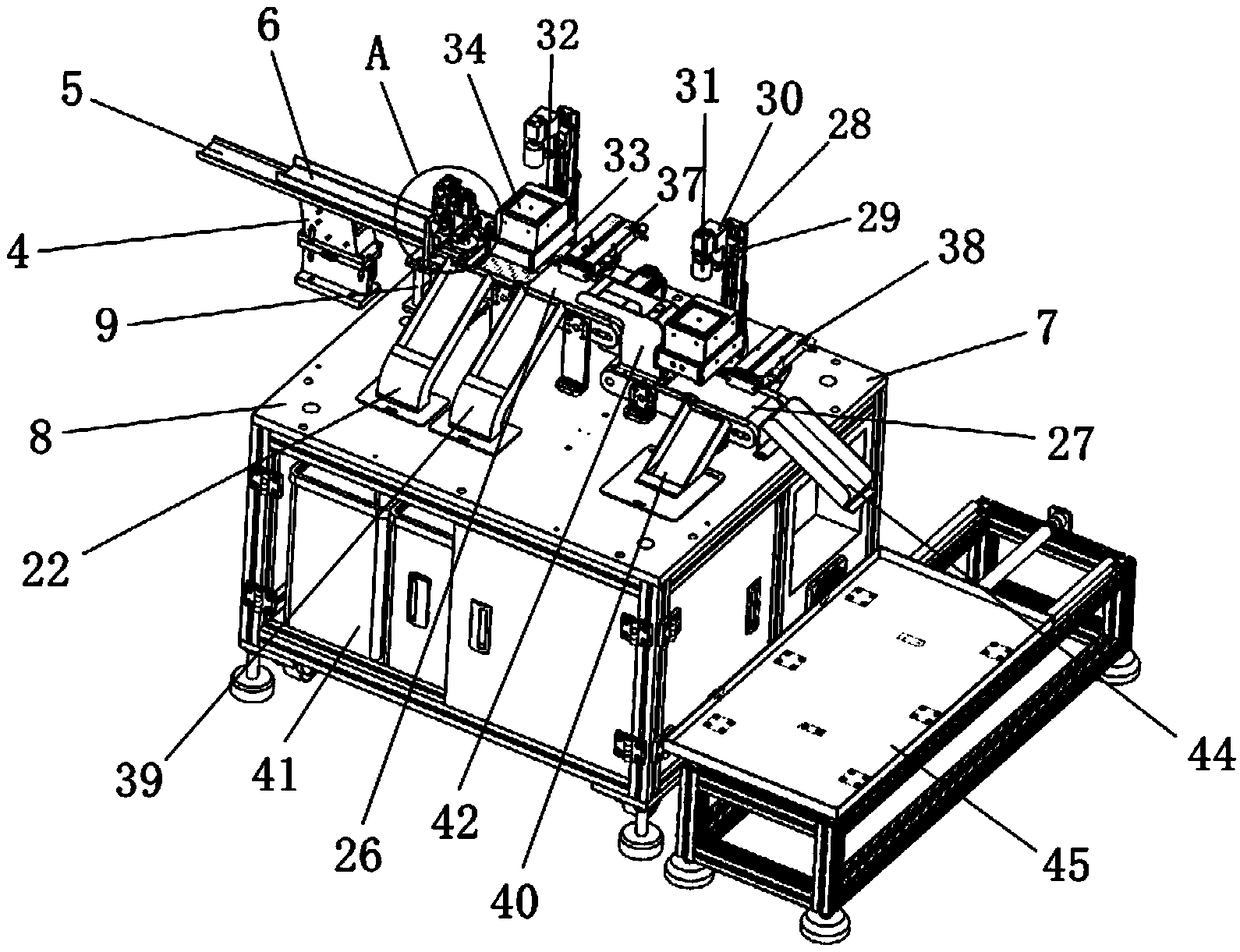

[0029] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0030] Such as Figure 1 to Figure 7As shown, an auto parts support plate detection device includes: a feeding mechanism; the feeding mechanism includes a storage bin 2 and a vibration plate 3; the outlet of the storage bin 2 is located above the vibration plate 3, and one side of the vibration plate 3 is provided with Feed flow channel 5; through the combined use of storage bin 2 and vibrating plate 3, the incoming materials of scattered products can be arranged in the same direction, storage bin 2 can store products, reduce the number of manual feeding, deformation detection mechanism; deformation The detection mechanism includes a jaw cyli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap