Thread rolling die cleaning device

A technology of cleaning device and rolling wheel, applied in the field of finishing, can solve the problems of heavy rolling wheel, overturning of rolling wheel, product damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

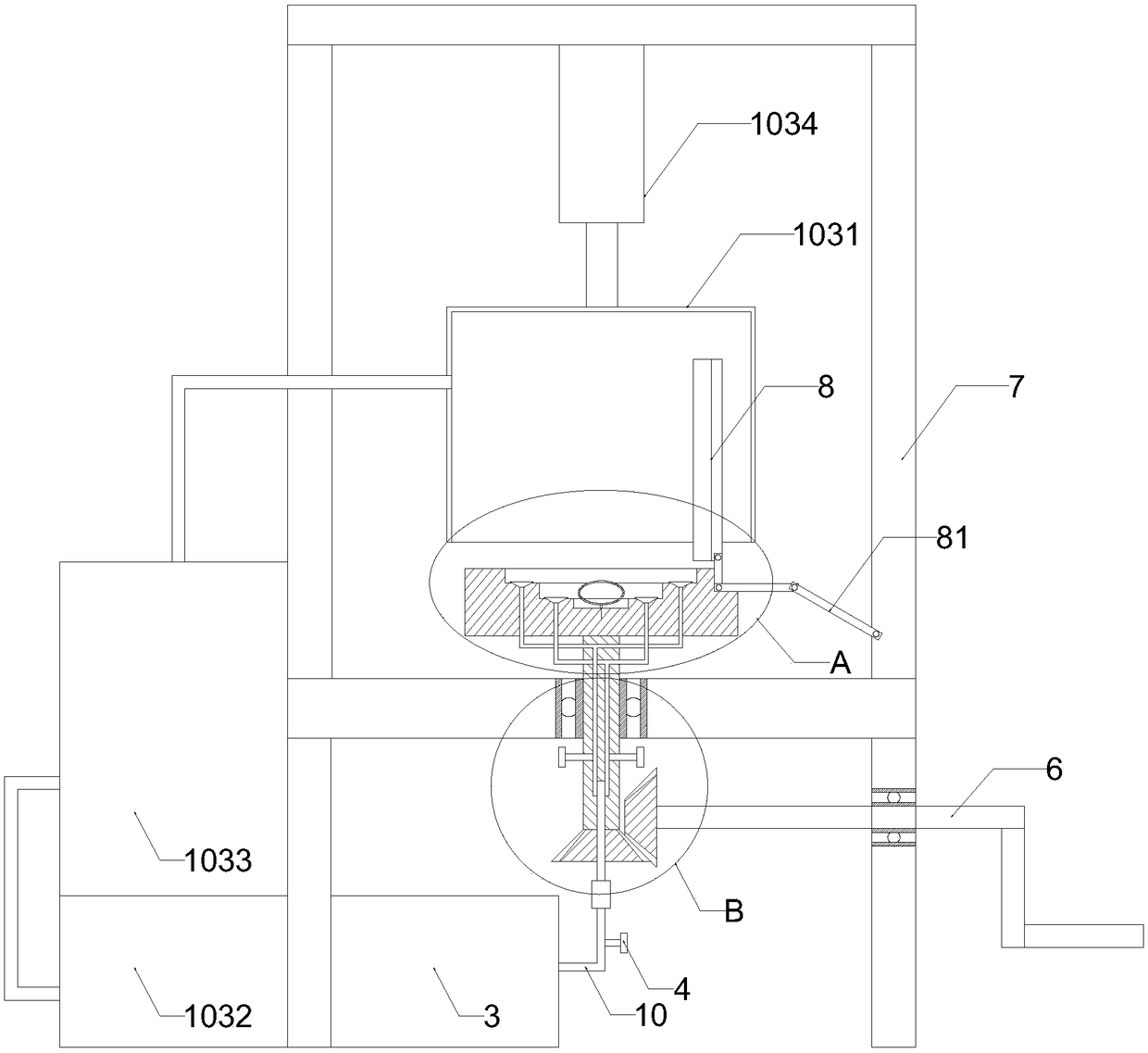

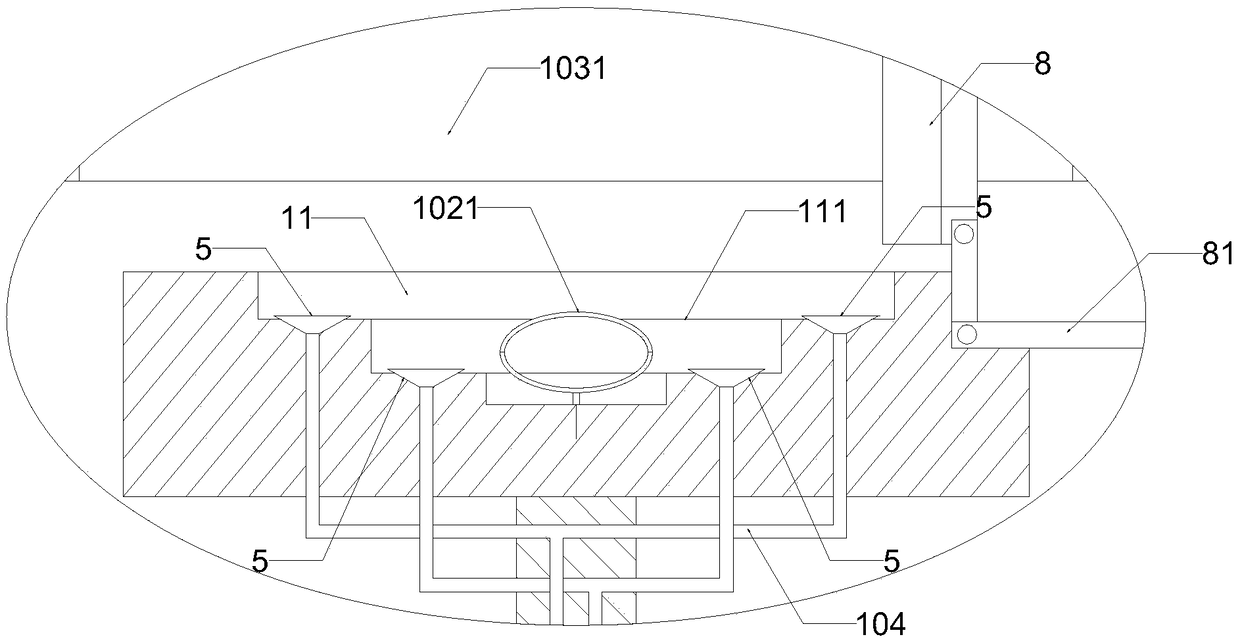

[0028] Such as Figure 1 to Figure 4 As shown, the thread rolling wheel cleaning device includes a base 1, a bevel gear 2, an air pump 3, a valve 4, a suction cup 5, a rocker 6, a fixed frame 7, and a broom 8;

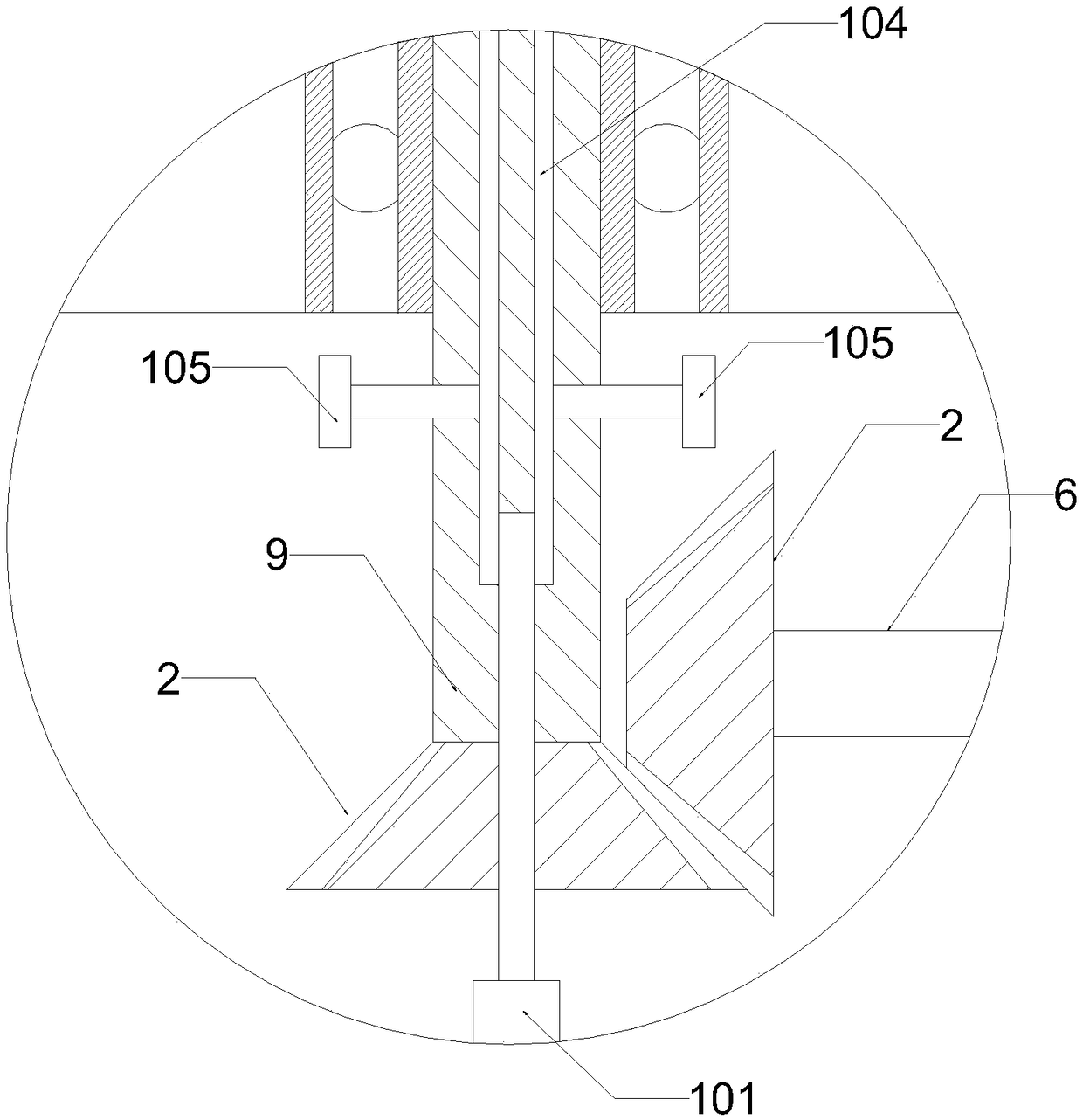

[0029] The lower part of the base 1 is fixedly connected with a rotating shaft 9, the rotating shaft 9 is rotatably sleeved on the fixed frame 7, the lower end of the rotating shaft 9 is connected with a bevel gear 2, the rocking bar 6 is rotatably fixedly connected with the fixed frame 7, and the rocking bar One end of 6 is also equipped with a bevel gear 2; the bevel gear 2 on the rocker 6 meshes with the bevel gear 2 on the rotating shaft 9;

[0030] The upper surface of the base 1 is horizontal, and the upper surface of the base 1 is provided with a circular groove 11; the center of the groove coincides with the axis of the rotating shaft 9; the suction cup 5 is installed in the groove; the suction cup 5 passes through the rotary joint 101 and the hose 10 in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com