Method for improving quality of sand core

A quality, sand core technology used in the field of core box design and fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

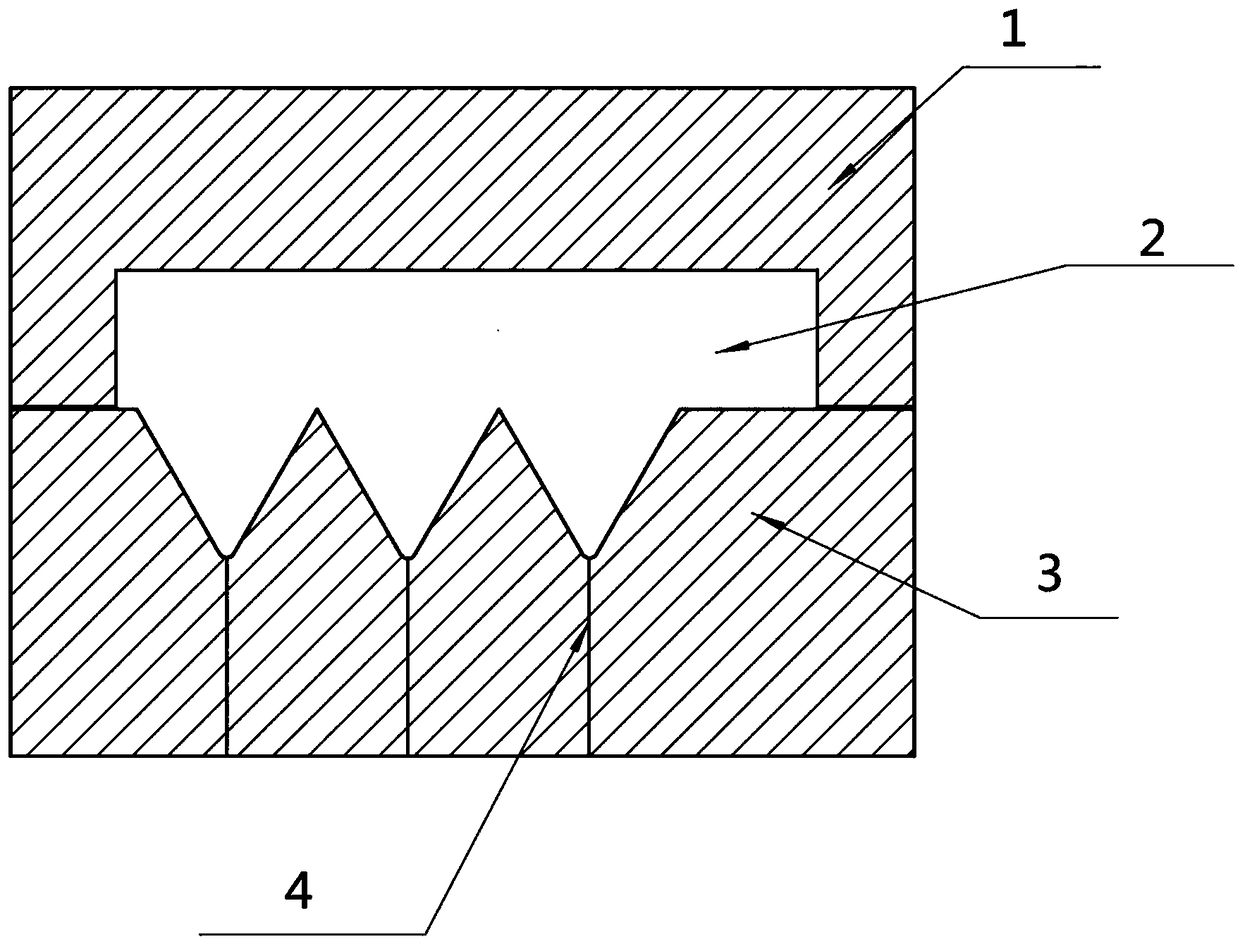

[0017] Such as figure 1 Shown: the present invention discloses a method for improving the quality of sand cores. When the core box is making cores, when the interior of the core box cavity has complex curved surfaces and narrow small cavities, it is not suitable to use exhaust plugs or ejector rods to exhaust air. In some cases, wire cutting is used in the core box design and production process to process these narrow positions of the core box to form a wire cutting exhaust groove 4 connecting the inside and outside of the core box cavity.

[0018] The exhaust groove 4 is a slit formed by molybdenum wire cutting, and the width of the slit is 0.14-0.16mm.

[0019] The exhaust groove 4 is located at the sharp corner position inside the cavity, and these positions cannot be provided with exhaust plugs and ejector rods.

Embodiment 2

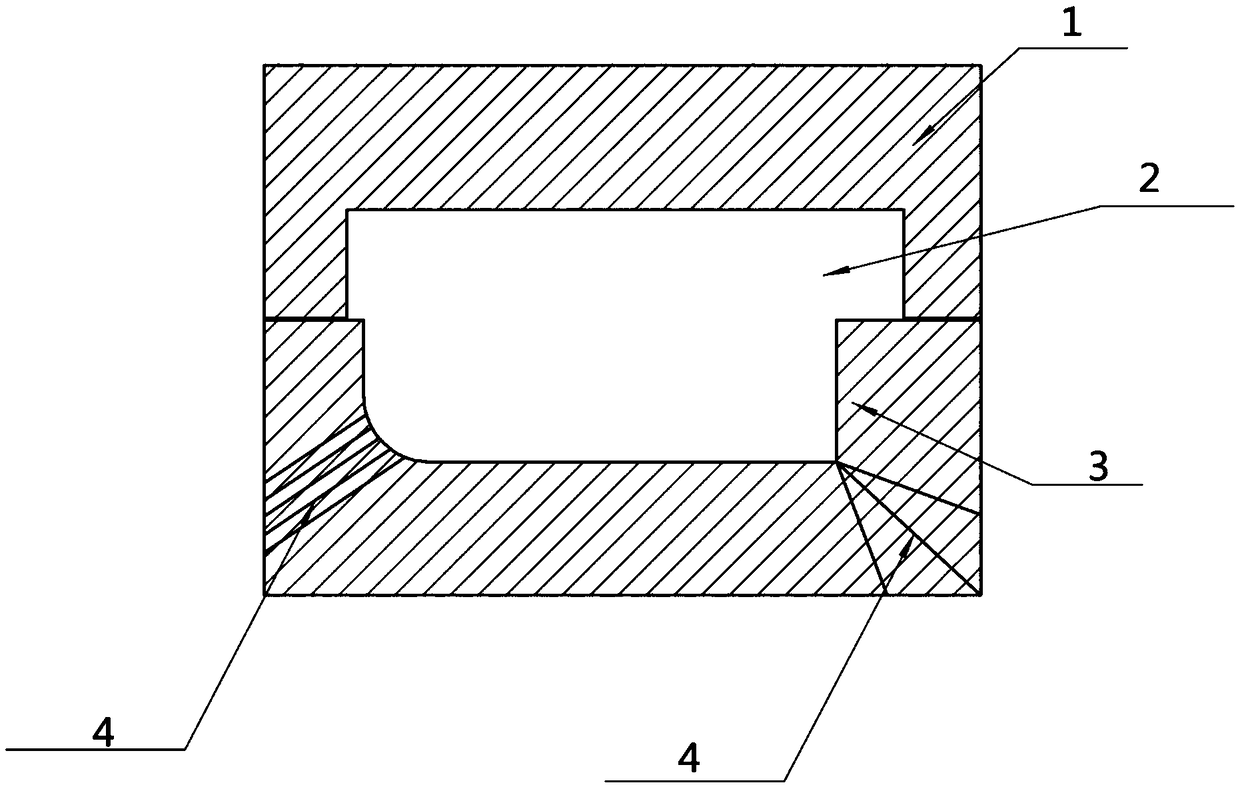

[0021] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the exhaust groove is located at the rounded corner or the corner of the core box, and these positions cannot be provided with exhaust plugs and ejector pins.

[0022] Working principle of the present invention:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com