Non-woven paper cloth processing device for controlling water outlet rate through air blowing

A method of controlling and processing device technology, applied to textiles and papermaking, papermaking, papermaking machines, etc., can solve problems such as poor practicability, different amount of slurry in forming belts, and difficulty in forming predetermined patterns, etc., to achieve simple and flexible use, and realize Pipeline processing, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of the embodiments of the present invention. Apparently, the described embodiments are some of the embodiments of the present invention, not all embodiments. Based on the described embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art belong to the protection of the present invention. scope.

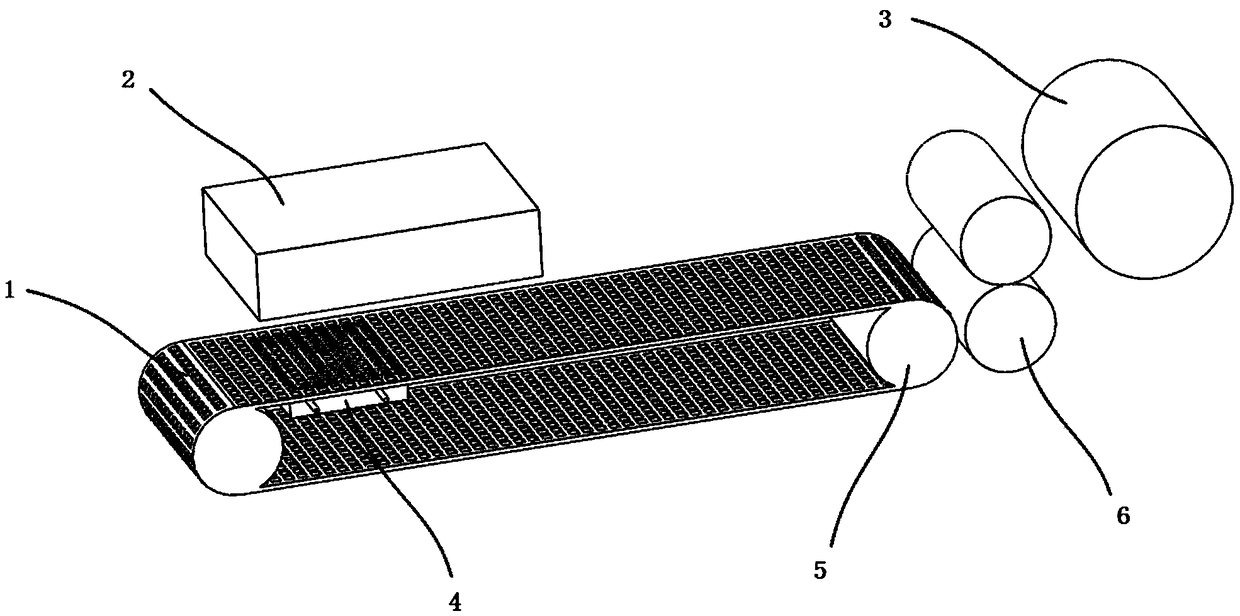

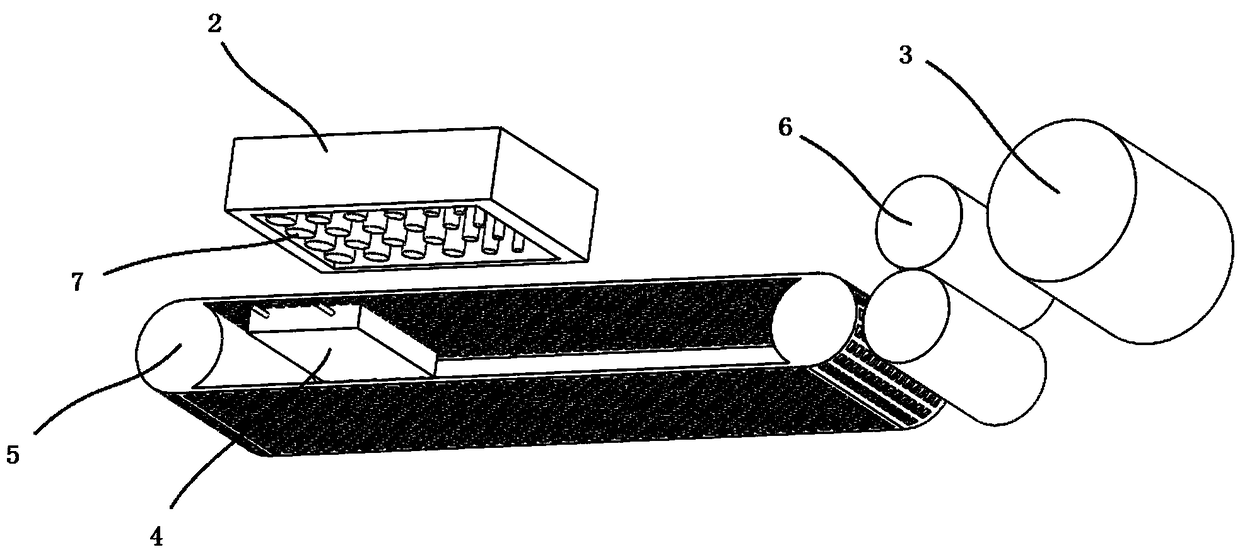

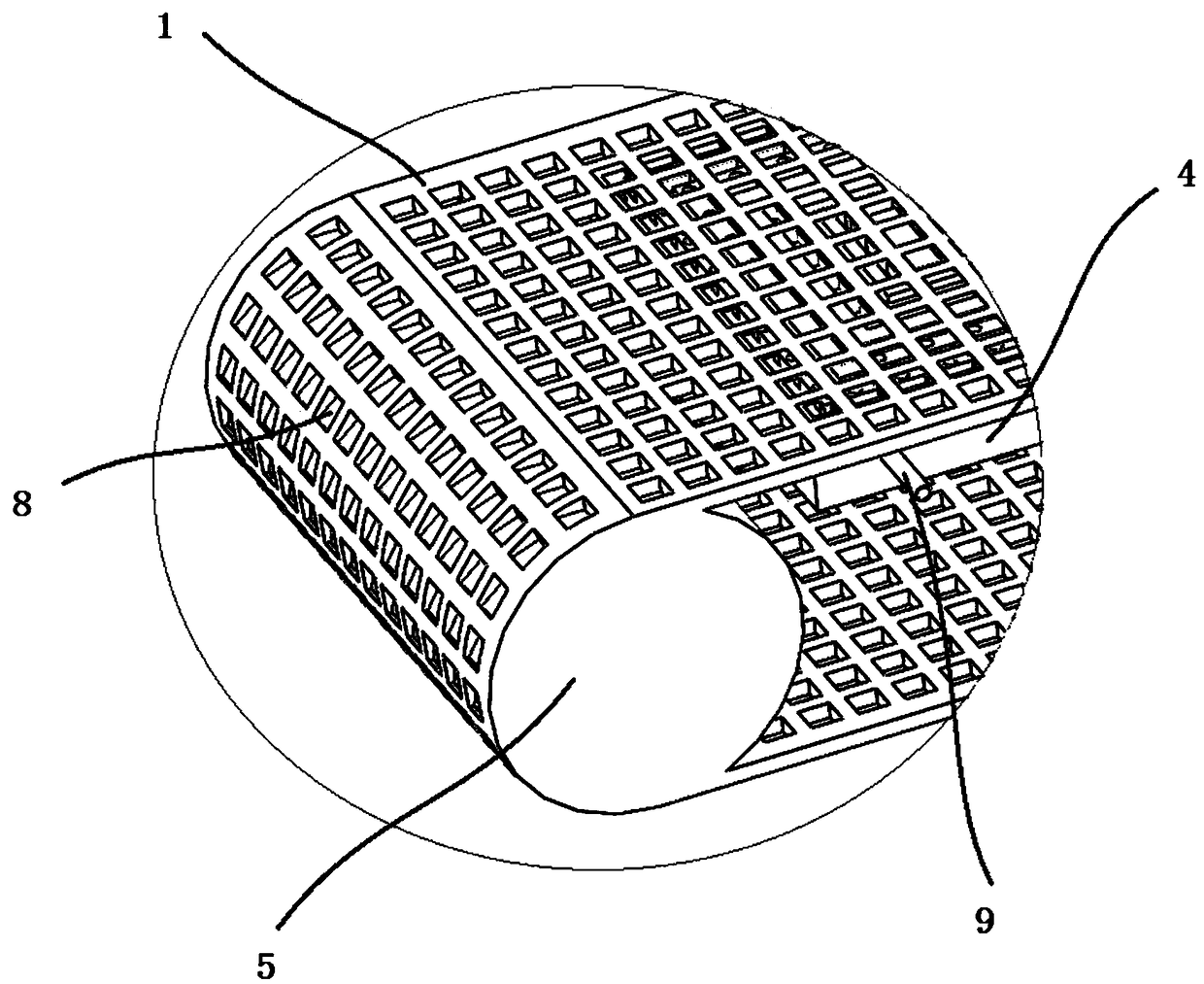

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a non-woven paper cloth processing device that controls the water yield by blowing air, including: a forming belt 1, an air blowing mechanism 4 and a slurry box 2.

[0030] Specifically, the molding belt 1 is provided with several mesh holes 8, and at least one slurry box 2 is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap