Vacuum sweeper dust bin with multistage dust-fall function

A vacuum cleaner and dust reduction technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of uneven ash falling in the dust box, inability to sprinkle water, and heavy manual workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

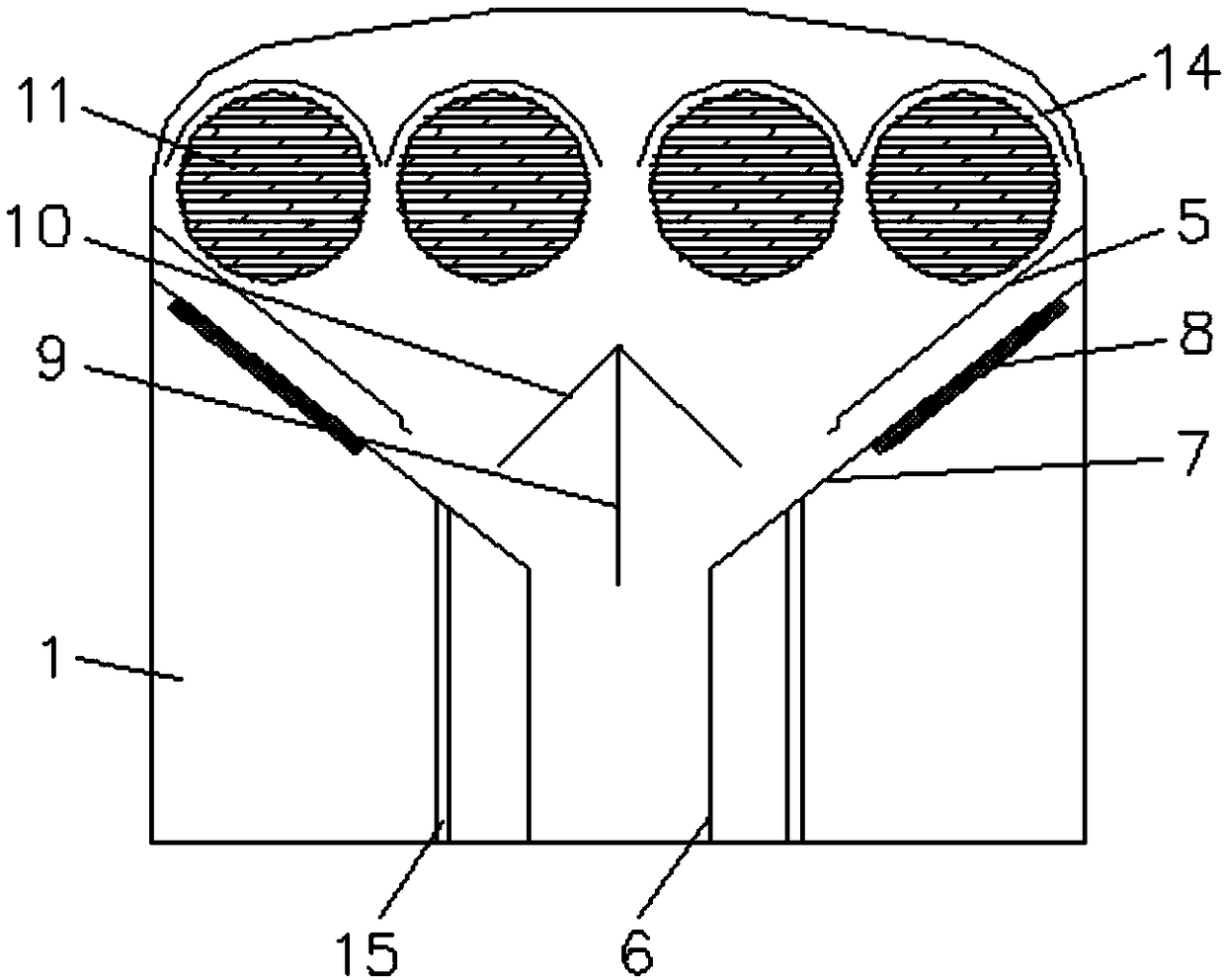

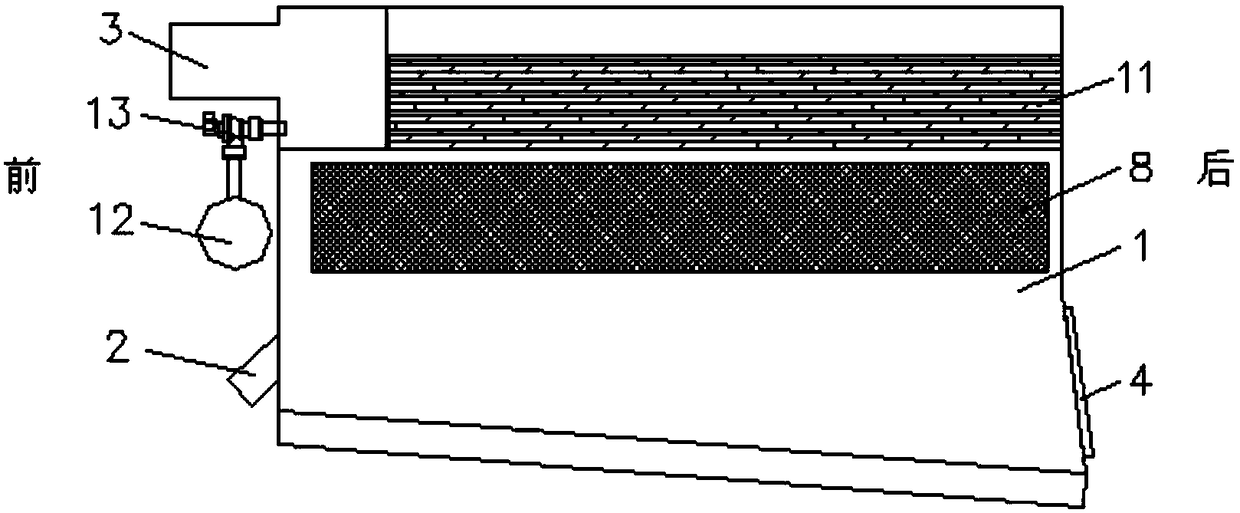

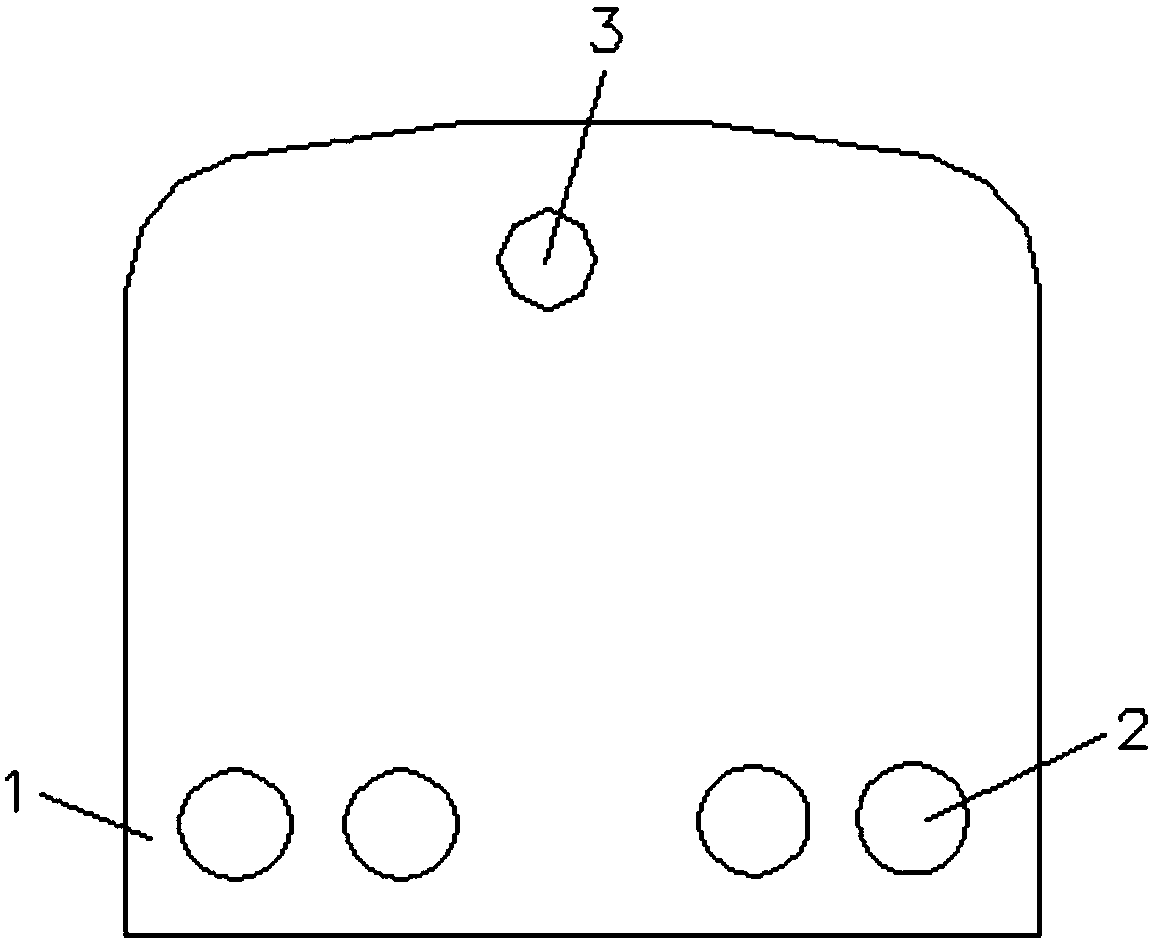

[0033] Such as Figure 1 to Figure 4 As shown, the present invention provides a dust collection car dust box with multi-stage dust reduction function, comprising a box body 1, a plurality of air inlets 2 are provided at the lower part of the front end of the box body 1, and the air inlets 2 are arranged on both sides near the front end, located at The air inlets 2 on both sides are respectively connected with the compartments on both sides of the box body 1. Each air inlet 2 is connected with a suction pipe, and the lower end of the suction pipe is close to the ground; 3. The pipe is connected with the fan, and the fan works to pump out the gas in the box 1 to form a negative pressure in the box 1, so that the garba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com