A dust removal device for coal mine safety

A dust removal device and coal mine safety technology, which is applied in safety devices, mining devices, dust prevention, etc., can solve problems such as unsatisfactory dust removal effect, achieve the effect of shortening dust removal time, improving dust removal efficiency, and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

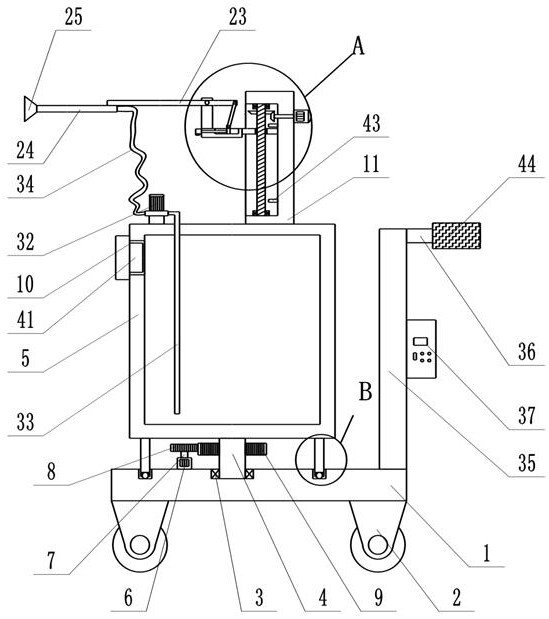

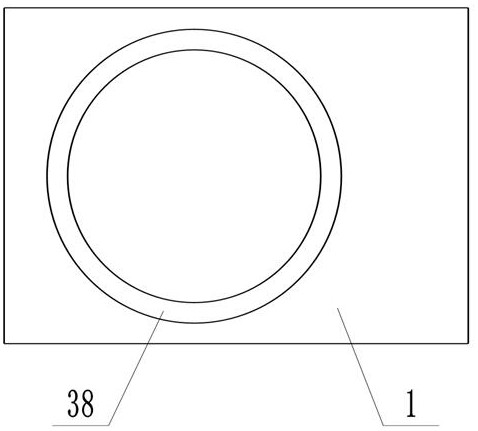

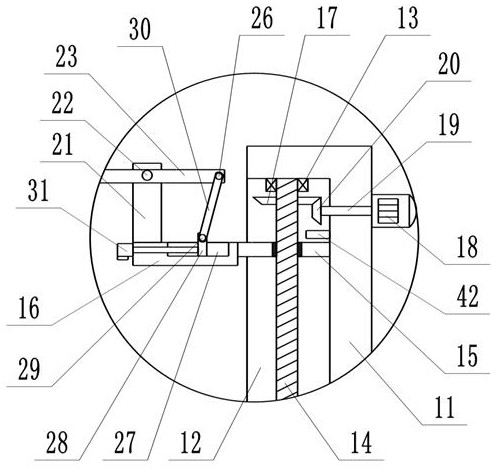

[0024] see Figure 1-4, a dust removal device for coal mine safety, comprising a bottom plate 1, moving wheels 2 are arranged at the four corners of the bottom of the bottom plate 1, a first rolling bearing 3 is fixedly connected in the groove at the midpoint of the top of the bottom plate 1, and the inside of the first rolling bearing 3 A support shaft 4 is movably connected, and the top of the support shaft 4 runs through the first rolling bearing 3 and extends to the outside of which a water tank 5 is fixedly connected. The top of the bottom plate 1 and the position corresponding to the water tank 5 are provided with an annular chute 38, and the left and right sides of the bottom of the water tank 5 And the positions corresponding to the annular chute 38 are all fixedly connected with supporting legs 39, the bottom of the supporting legs 39 runs through the annular chute 38 and extends to its inside, the groove at the bottom of the supporting legs 39 is movably connected wit...

Embodiment 2

[0027] A lot of parts are arranged on the top of the water tank 5, and its center of gravity is often not at its geometric center. If the water tank 5 is driven to rotate through the support shaft 4 in Embodiment 1, the water tank 5 will inevitably produce centrifugal rotation, and this centrifugal rotation A shearing force in the horizontal direction will be generated on the supporting rotating shaft 4 , thereby increasing the probability of damaging the supporting rotating shaft 4 .

[0028] exist figure 1 On the basis of Figure 5 to Figure 7 , different from Embodiment 1, in this embodiment, an annular chute 38 is provided at the top of the bottom plate 1 and corresponding to the position of the water tank 5, and an upper annular plate 45 is provided below the water tank 5, and the water tank 5 is fixedly connected to the upper annular plate 45, It can also be connected by the supporting legs 39 shown in Embodiment 1. The upper annular plate 45 is arranged on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com