Single-galvanometer big-area additive manufacturing laser forming equipment and forming method

A laser forming and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve problems such as intensified spheroidization effect in the splicing area, uneven temperature field distribution, and processing failure, so as to avoid forming failure in the splicing area and avoid coordinated control process , The effect of reducing R&D and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

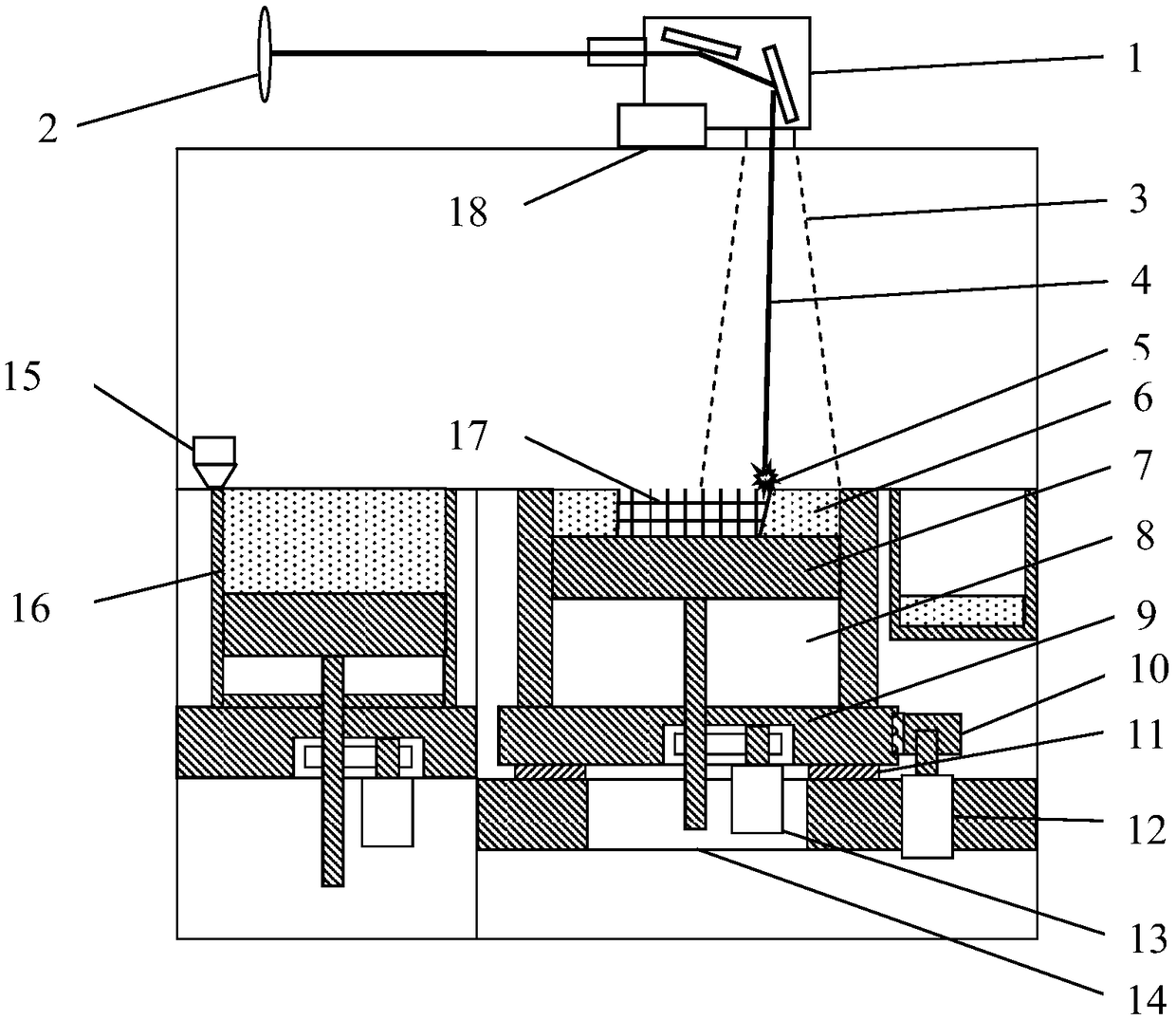

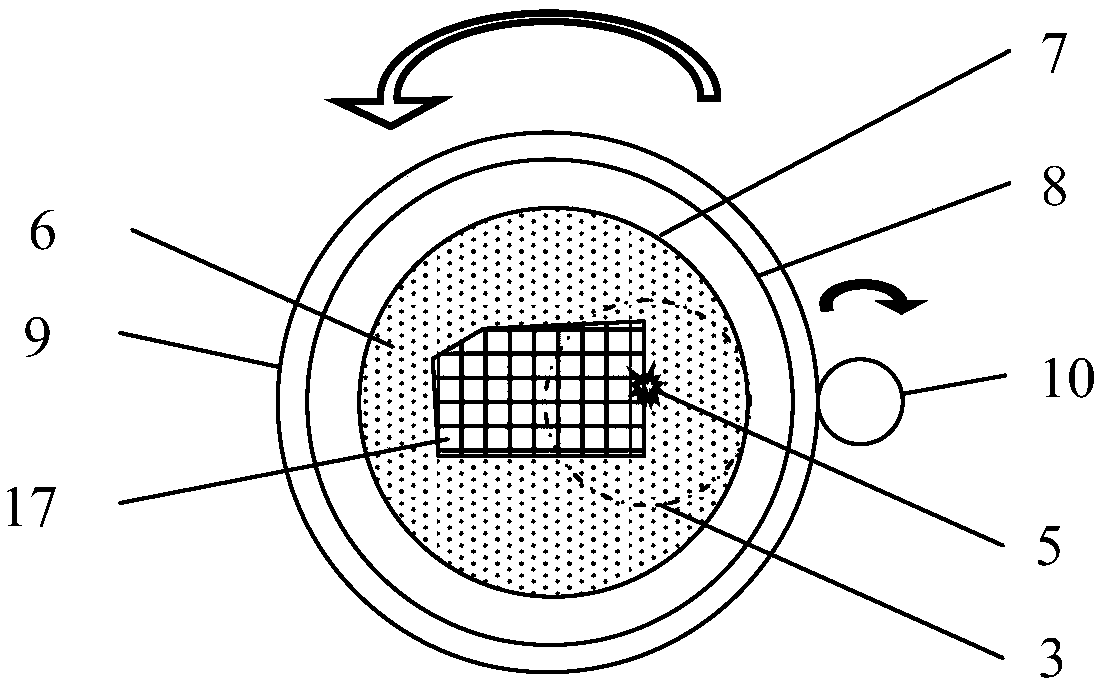

[0045] see figure 1 and figure 2 , this embodiment provides a laser forming equipment for large-format additive manufacturing with a single vibrating mirror, including a vibrating mirror 1, a point light source 2, a forming chamber 8, a forming substrate 7, a transmission mechanism 13, and a fixed platform 14. The vibrating mirror 1 is installed on the On the mirror fixing table 18, the forming chamber 8 can rotate around its central axis, so that the scanning area of the laser on the forming surface is rotated relative to the forming surface.

[0046] As a preferred embodiment, the bottom of the forming chamber 8 is equipped with a rotating assembly that can rotate the forming chamber around its central axis. During the laser forming process, the forming chamber drives the forming substrate to rotate axially, and the forming surface rotates, so that the scanning The diameter of the field is doubled, and the area of the scanning field is quadrupled.

[0047] As a furthe...

Embodiment 2

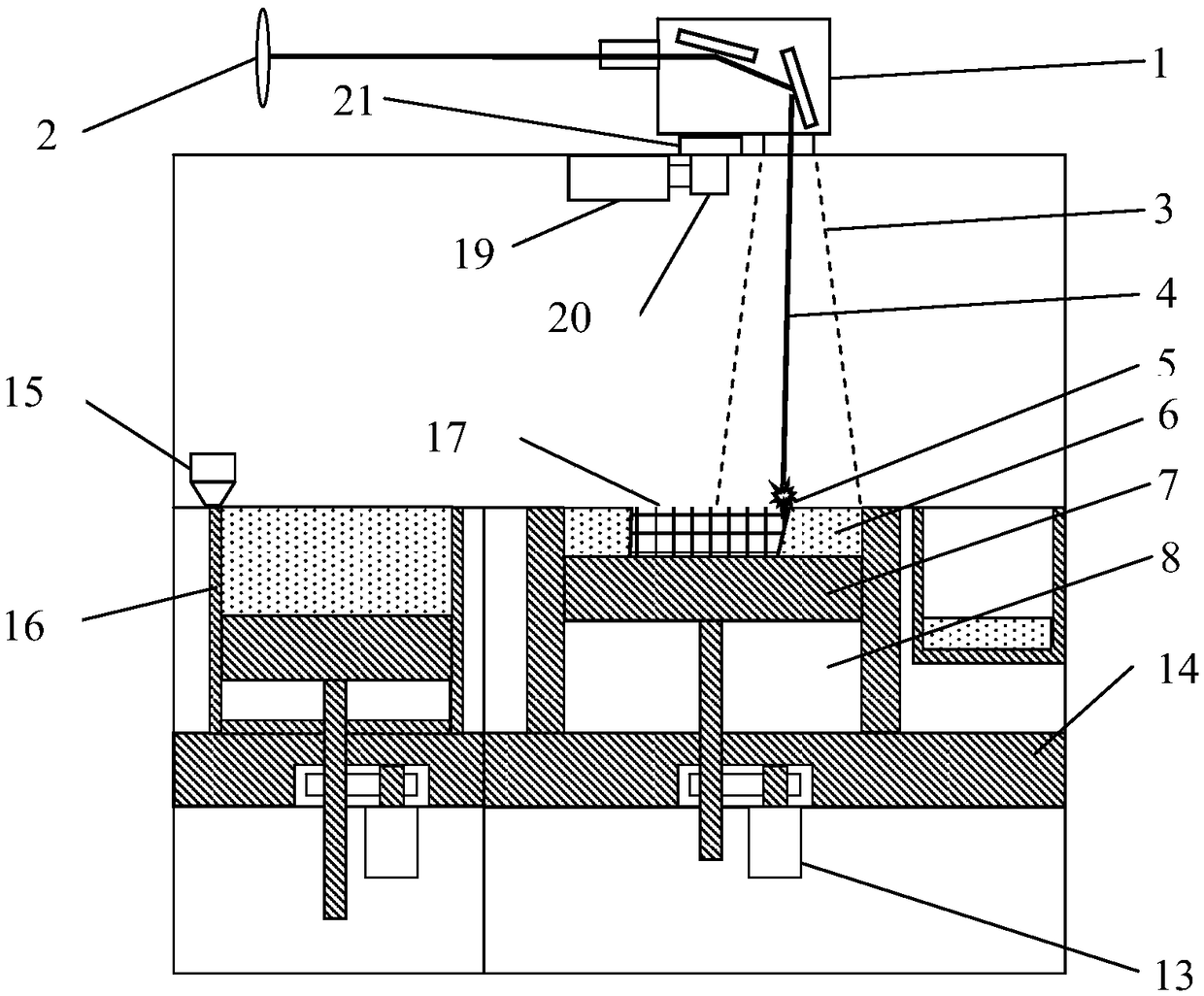

[0051] see image 3 and Figure 4 , this embodiment provides a laser forming equipment for large-format additive manufacturing with a single vibrating mirror, including a vibrating mirror 1, a point light source 2, a forming chamber 8, a forming substrate 7, a transmission mechanism 13, and a fixed platform 14, and the vibrating mirror 1 can be formed around The central axis of the bin 8 rotates, so that the scanning area of the laser on the forming surface is rotated relative to the forming surface.

[0052] As a preferred embodiment, the bottom of the vibrating mirror 1 is equipped with a rotating device that can rotate the vibrating mirror around the central axis of the forming chamber 8. When the vibrating mirror is rotated during the laser forming process, the scanning area of the single vibrating mirror on the forming substrate will rotate. , so that the diameter of the scanning area is doubled, and the area of the scanning area is quadrupled.

[0053] As a furth...

Embodiment 3

[0056] see figure 1 and Figure 5 , the present embodiment provides a method for forming laser forming equipment using the large-format additive manufacturing laser forming device described in Embodiment 1, comprising the following steps:

[0057] 1) During the pre-processing laser path planning process of the formed part 17, the scanning area of each layer is fan-shaped, and then the information of the formed part is imported into the numerical control system of the laser forming equipment for laser forming;

[0058] 2) The forming surface laser 5 scans in its laser scanning range 3, and at the same time controls the rotating base 9 to continuously rotate so that the forming surface rotates synchronously;

[0059] 3) The forming surface laser 5 forms a scanning path 27 for each fan-shaped area 26 and scans it. After the forming surface rotates a circle, the central area 25 is scanned separately to complete the laser forming process of the current layer;

[0060] 4) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com