Additive-subtractive four-station near-net forming equipment and forming method

A near-net-shape, four-station technology, applied in the field of additive manufacturing, which can solve problems such as poor rigidity, deviation of the axis, and changes in the position coordinates of the forming point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

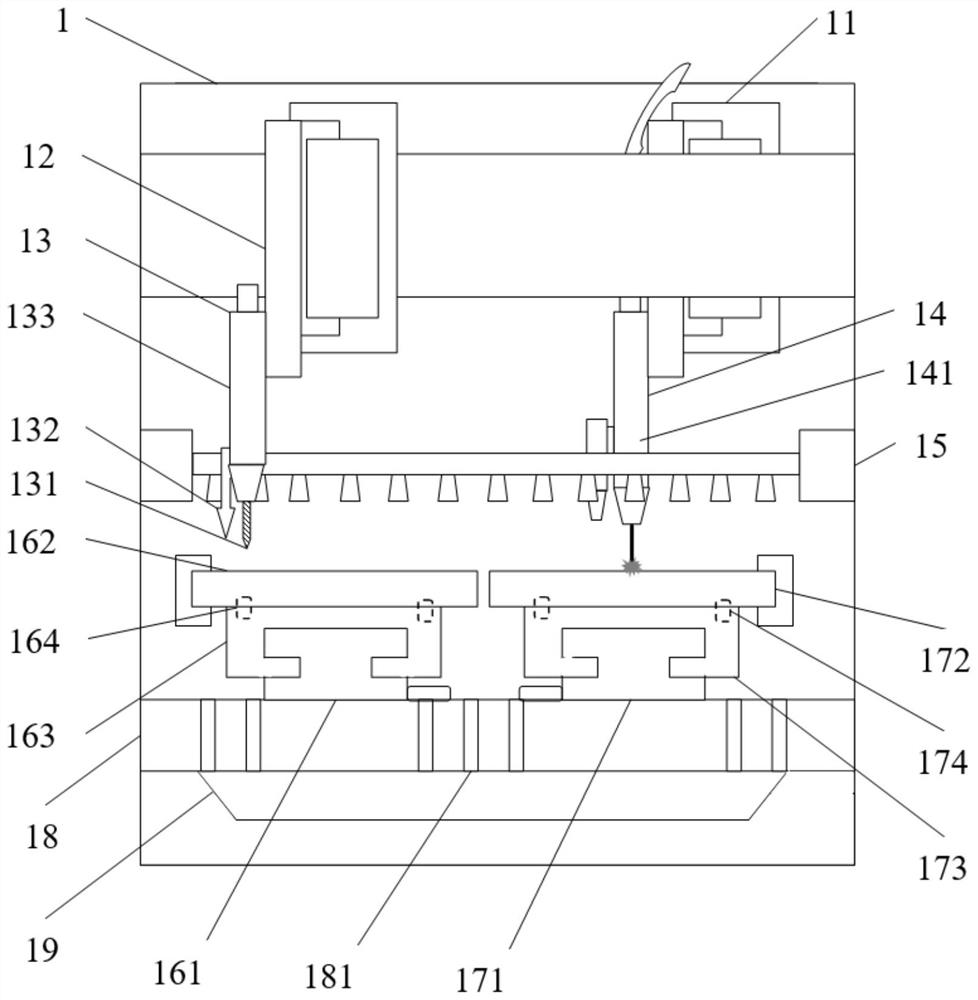

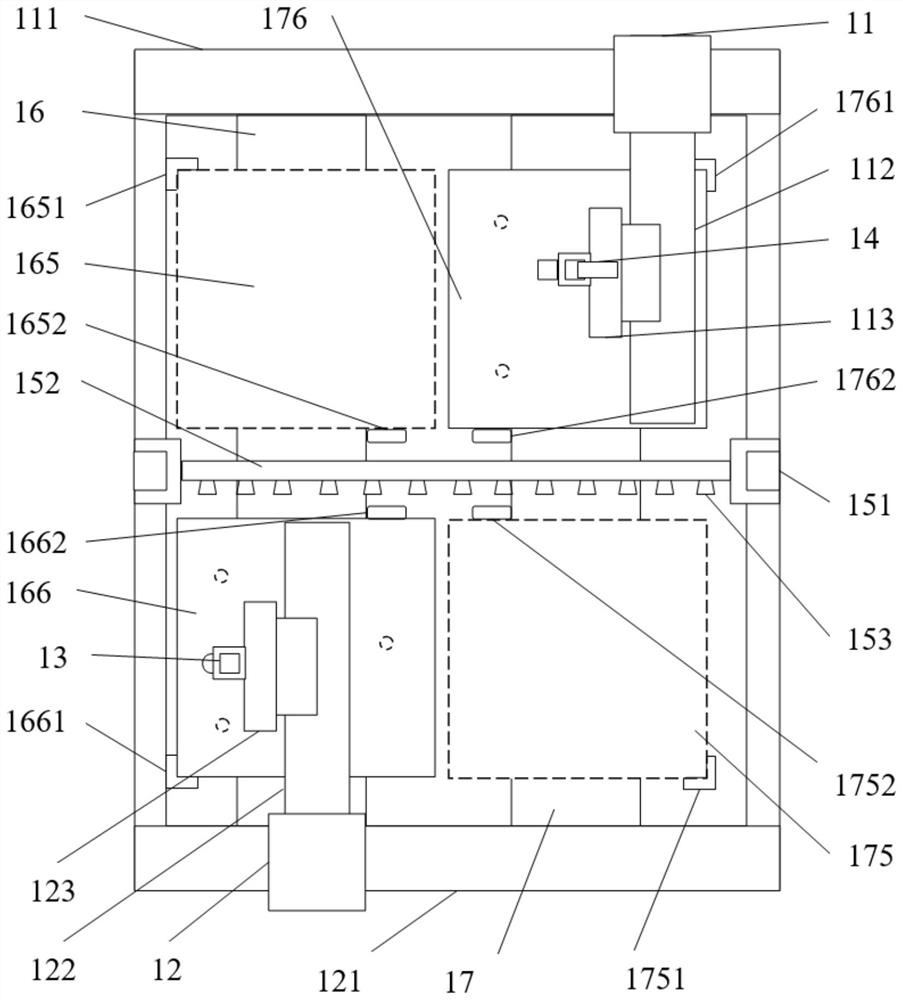

[0079] Below in conjunction with accompanying drawing, the present invention is described in further detail:

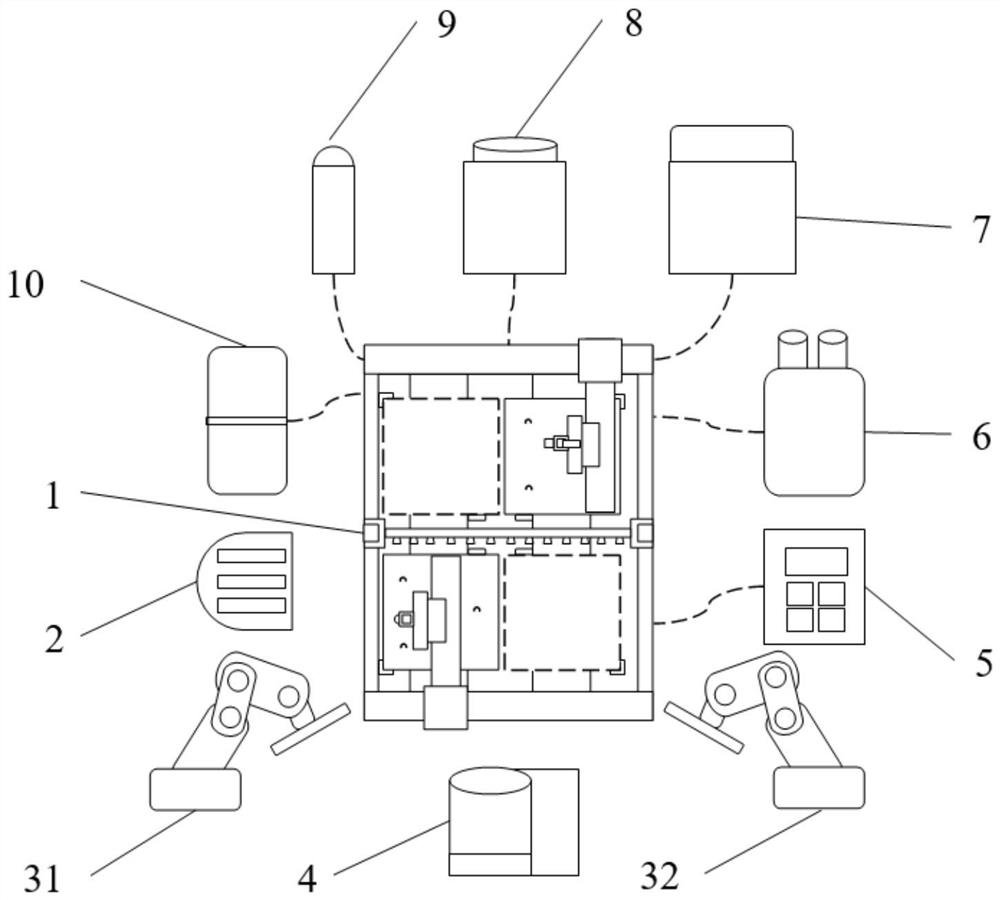

[0080] Such as Figure 1 to Figure 3 As shown, the present invention provides a near-net-shaping equipment with four stations for adding and subtracting materials, including a main body mechanism 1, a control mechanism 5 connected to the main body mechanism 1, a feeding device 6, an energy mechanism 7, a cooling device 8, and an air supply mechanism 9. The purification device 10, and the tool magazine 2, the cleaning device 4, and the robot loading and unloading devices 31, 32 placed around the main body mechanism 1 of the equipment, wherein the tool magazine 2, the cleaning device 4, the feeding device 6, the energy mechanism 7, and the cooling device 8. The air supply mechanism 9, the purification device 10, and the robot loading and unloading devices 31, 32 are all commercially available products, which can be assembled and debugged directly with the main body mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com