A Collapsible Loess Subgrade Treatment Method Based on the Principle of Lightweight Soil Weight Reduction

A technology for collapsible loess and treatment methods, which is applied in the field of permeable road construction in sponge cities in collapsible loess areas, which can solve the problems of insufficient storage and utilization of rainwater resources, large capital investment, and large engineering volume, etc., and achieve urban improvement. Ecological environment, improvement of living environment, and effect of reducing engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above cotton stalk fiber lightweight soil comprises the following steps:

[0033] First, the cotton stalks are crushed, peeled, fiberized, washed and dried in turn to obtain cotton stalk fibers; then water is added to the mixture of raw soil, cotton stalk fibers, cement and sand to obtain cementitious materials; finally Mix EPS particles with cementing materials to make lightweight soil with cotton stalk fibers, and the dosage of cotton stalk fibers, cement, sand, EPS particles and water is 0.4%-0.8% and 2%-4% of the weight of the raw soil in sequence , 6% to 12%, 1% to 1.5% and 30% to 50%.

[0034] The preparation method of described cotton stalk fiber specifically comprises the following steps:

[0035] 1.1) Crushing the cotton stalks in a pulverizer to obtain cotton stalks cut to a length of 50 mm to 300 mm;

[0036] 1.2) The cotton stalks cut off in step 1.1) are sequentially soaked and pith removed to obtain the cotton stalk bark;

...

Embodiment 1

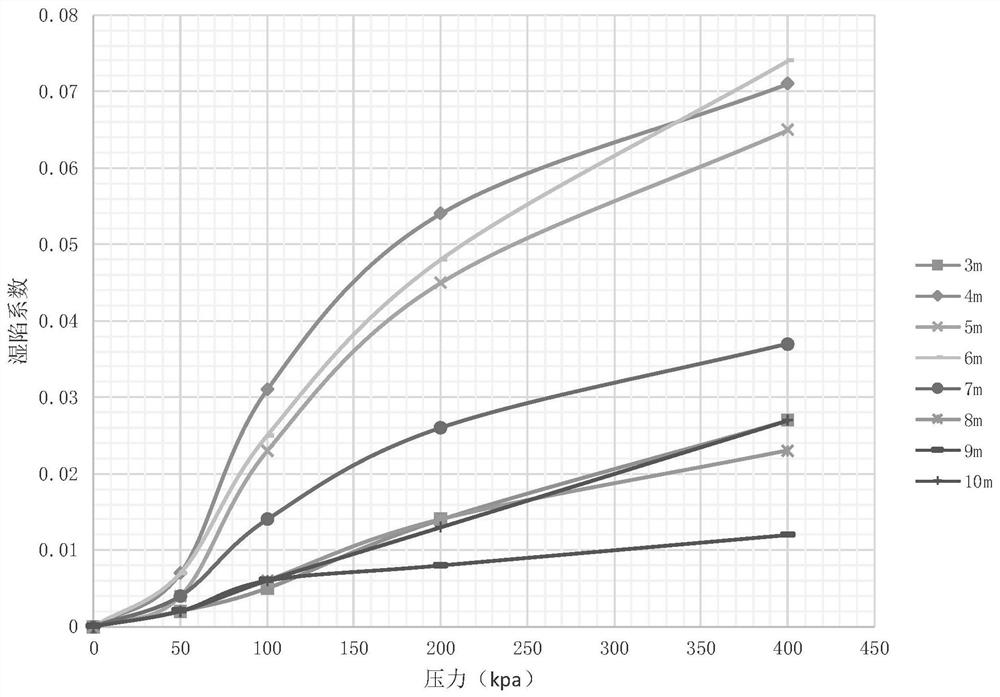

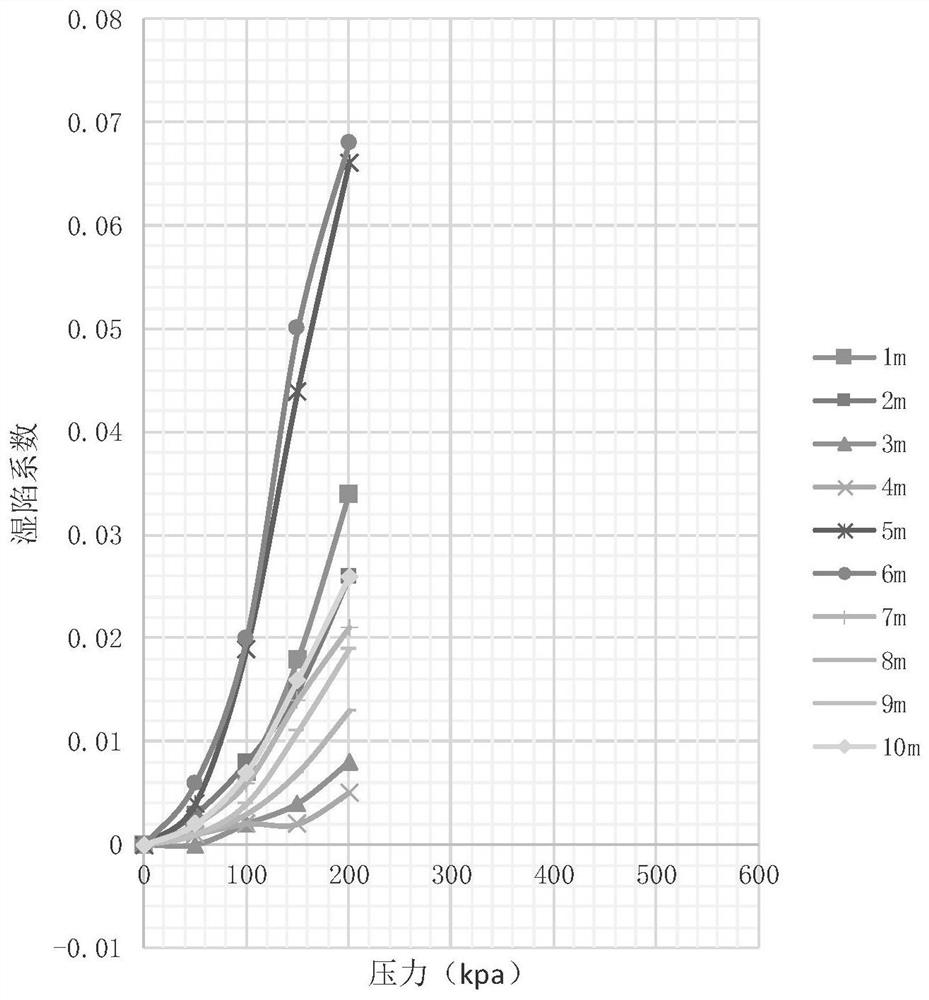

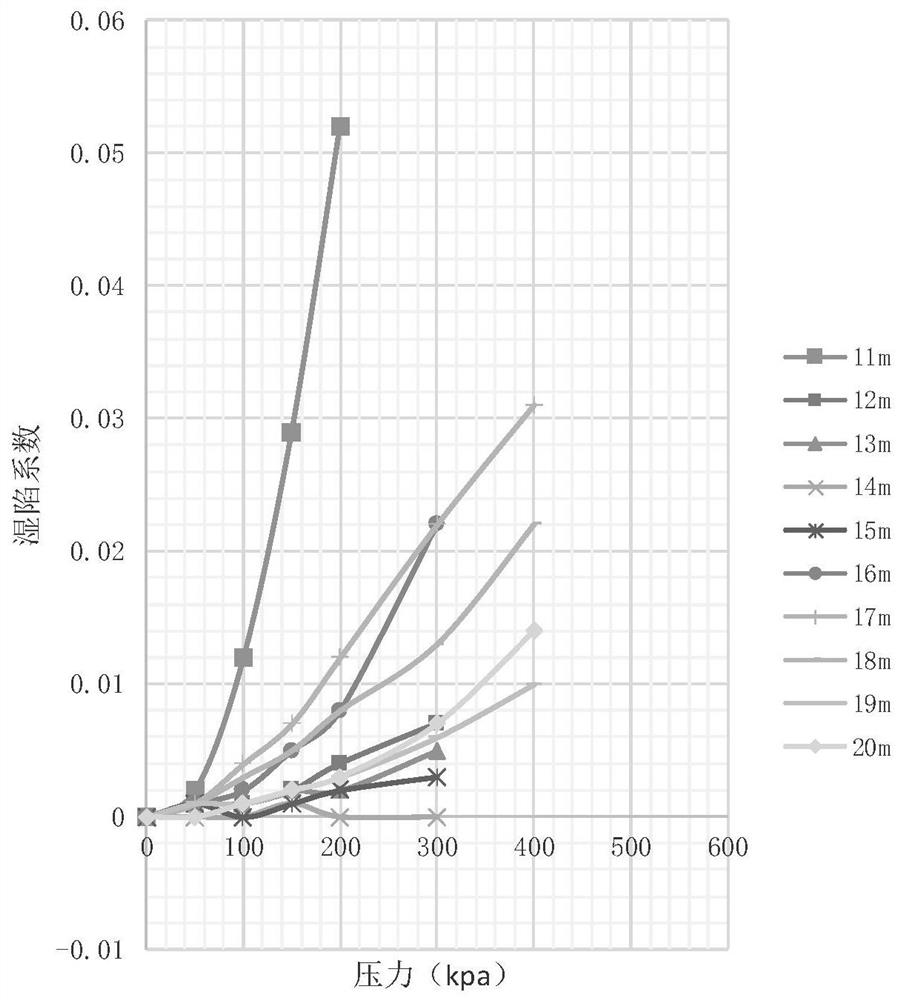

[0046] The first step is to collect soil samples from site 1 (collapsible loess area in Guanzhong area) through geological survey, and determine the physical parameters of different soil layers in site 1 through experiments, such as specific gravity, moisture content, density, dry density, and natural void ratio , saturation, according to the "SL237-1999 Geotechnical Test Regulations" method, use the above parameters to calculate the water content of 85% saturation of each layer of collapsible loess under different pressures (used to calculate the wet density of 85% saturation), saturation Wet density at 85% saturation, self-weight pressure (calculated based on wet density at 85% saturation), initial pressure of collapsibility, and collapsibility coefficient, see Table 1-1 (n=8). Among them, the collapsibility coefficient is a parameter to determine the degree of site collapsibility, and the relationship between the collapsibility coefficient and pressure at different depths is...

Embodiment 2

[0061] The first step is to collect soil samples from site 1 (collapsible loess area in Guanzhong area) through geological survey, and determine the physical parameters of different soil layers in site 1 through experiments, such as specific gravity, moisture content, density, dry density, and natural void ratio , saturation, and calculate self-weight pressure, initial pressure of collapsibility, and collapsibility coefficient, see Table 1-1, the relationship between collapsibility coefficient and pressure at different depths is as follows figure 1 shown.

[0062] In the second step, according to the calculation formulas of self-weight collapsibility Δzs and collapsibility Δs in "GB50025-2004 Building Code for Collapsible Loess Areas", calculate the self-weight collapsibility and collapsibility of each layer and the total self-weight collapsibility ( The results are shown in Table 2-1 (counting from the surface to the bottom layer) and total collapsibility (counting from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com