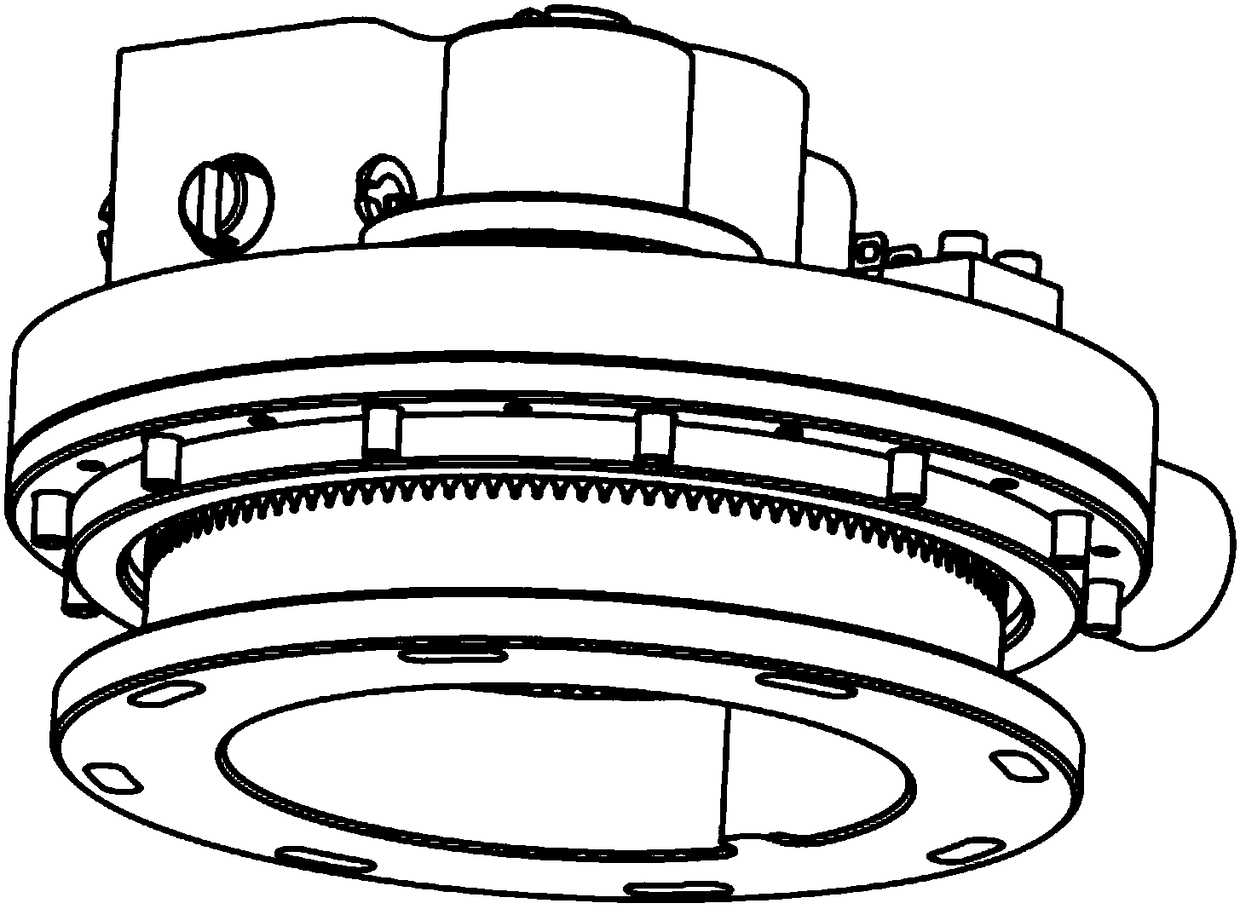

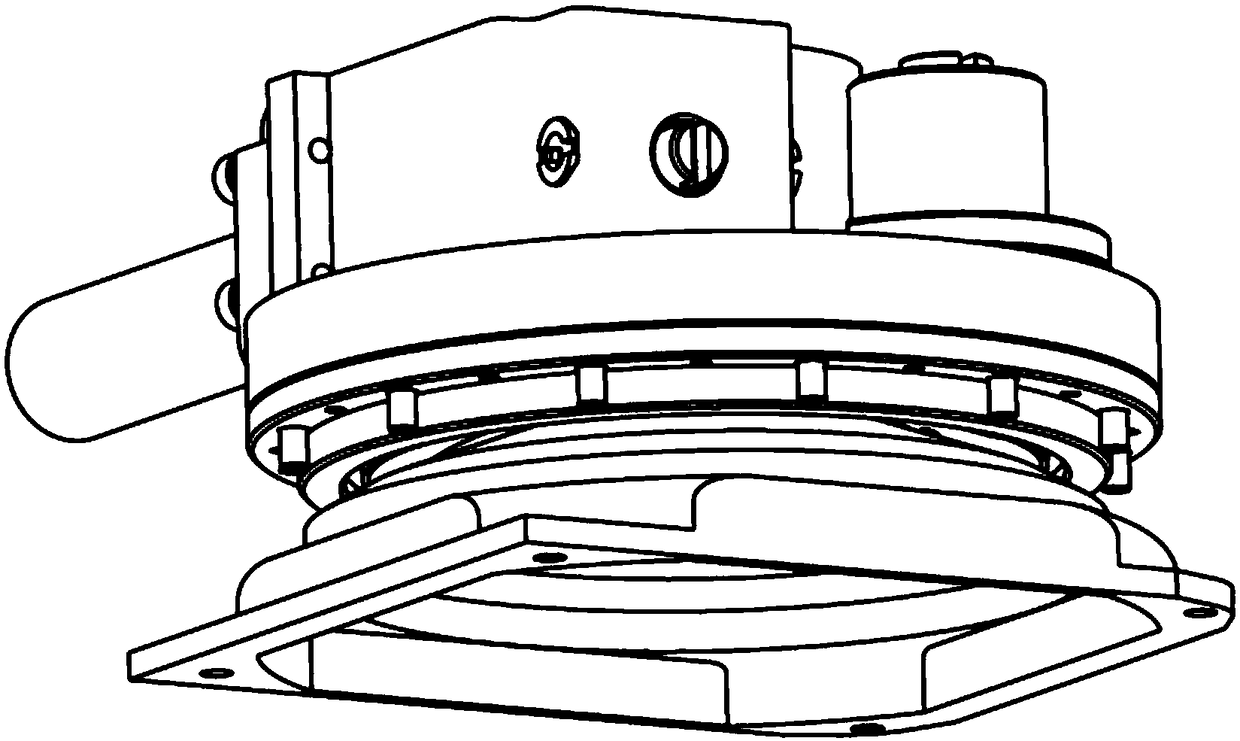

High-precision locking mechanism capable of resisting large impact and vibration

A locking mechanism, high-precision technology, applied in the direction of electromechanical devices, structural connections, mechanical equipment, etc., can solve the problems of poor resistance to shock and vibration, large locking mechanism, difficult locking accuracy, etc., to achieve self-locking Good performance and reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

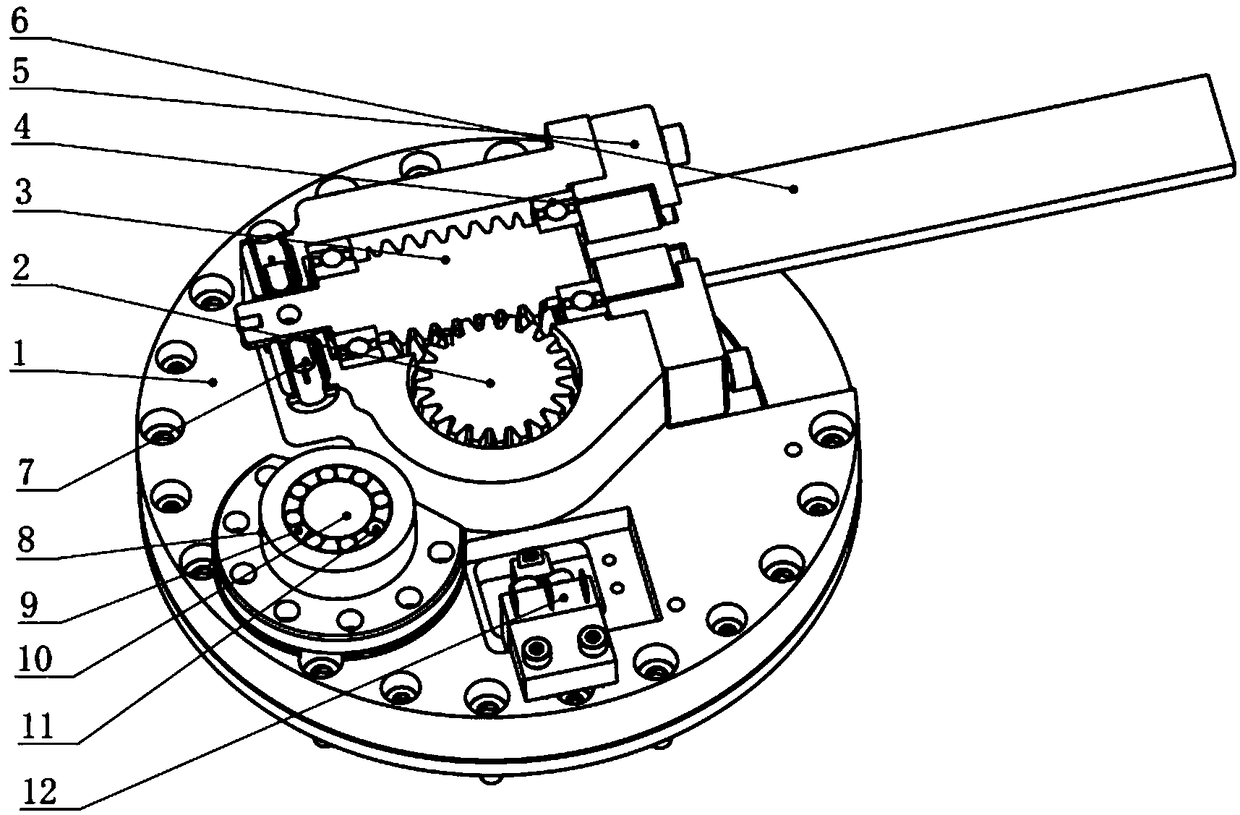

[0020] The present invention will be further described below in combination with the embodiments and with reference to the accompanying drawings.

[0021] A high-precision locking mechanism resistant to large shocks and vibrations, including a locking seat, a worm gear, a toothed plate, a bearing, a guide rod, and a dense ball shaft system. The locking seat (1) is the base of the locking mechanism, and the rest of the parts are installed on the locking seat (1), and the locking seat (1) can be fixed on the calibration device by screws. The worm wheel (2) is installed in the central circular hole of the locking seat, and the axial direction of the worm wheel (2) is supported by two angular contact ball bearings (4). A worm (3) is installed in the transverse hole of the locking seat (1) to cooperate with the worm wheel (2), and the axial direction of the worm (3) is also supported by two angular contact ball bearings (4). A locking motor seat (5) is installed at the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com