Determining the surface energy test method of fixed materials under variable temperature conditions based on mechanical tests

A test method and a technology for fixing materials, which are applied in the direction of material analysis, surface tension analysis, surface/boundary effects, etc., can solve the problems that affect the accurate test progress of the surface energy of solid materials, the surface of solid materials cannot be directly measured, and the surface energy cannot be accurately characterized. problem, to achieve the effect of simple structure, easy operation and accurate characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

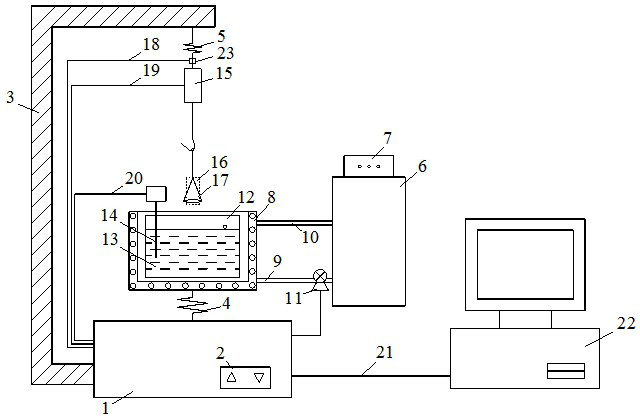

[0026] as attached figure 1 Said, the implementation of the present invention provides a device based on mechanical testing to determine the surface energy of solid materials under variable temperature conditions, including a control system, a constant temperature system and a test system; wherein the control system includes: a console 1, a constant temperature pool lift button 2. Support frame 3, constant temperature pool lifting device 4, sample lifting device 5, sample displacement data transmission line 18, force sensor data transmission line 19, temperature sensor data transmission line 20, console output line 21 and computer 22; among them, the constant temperature system Including: constant temperature water bath box 6, constant temperature water bath regulator 7, constant temperature pool 8, constant temperature pool inlet pipe 9, constant temperature pool outlet pipe 10 and peristaltic pump 11; the test system includes: solution pool 12, detection solution 13, temperat...

Embodiment 2

[0029] Implement a kind of device based on mechanical test to determine the surface energy of solid material under variable temperature condition, be on the basis of embodiment 1, further embodiment is to adjust the height of constant temperature pool 8 and solution pool 12 by lifting button 2 and lifting device 4, The adjustable height range is 100mm; the accurate lifting of the sample 16 and the platinum suspension ring 17 in the detection solution is realized through the sample lifting device 5 and the displacement sensor 23, the adjustable height range is 30mm, and the adjustable speed range is 1-20mm min -1 .

Embodiment 3

[0031] Implementation of a device based on mechanical tests to determine the surface energy of solid materials under variable temperature conditions is based on Example 1. A further embodiment is to regulate and maintain the temperature of the medium in the water bath box 6 through a thermostat 7. The medium contains but Not limited to water, oil, alcohol, liquid nitrogen, and the constant temperature medium is delivered to the constant temperature pool 8 by the constant temperature pool liquid inlet pipe 9 and the peristaltic pump 11, and the constant temperature pool is returned by the constant temperature pool outlet pipe 10, and the constant temperature pool 8 and the constant temperature pool are realized by continuous circulation of the constant temperature medium. The temperature inside the solution pool 12 is constant, and the medium temperature can be adjusted in the range of -30-+150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com