Pluggable structure capable of connecting integrated light steel wallboard with steel frame structure and pluggable method thereof

A plug-in structure and steel frame technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficulty in finding rods, cumbersome installation procedures, and difficulty in on-site management, so as to save labor and construction time and improve the installation process. Quick and easy, tight and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

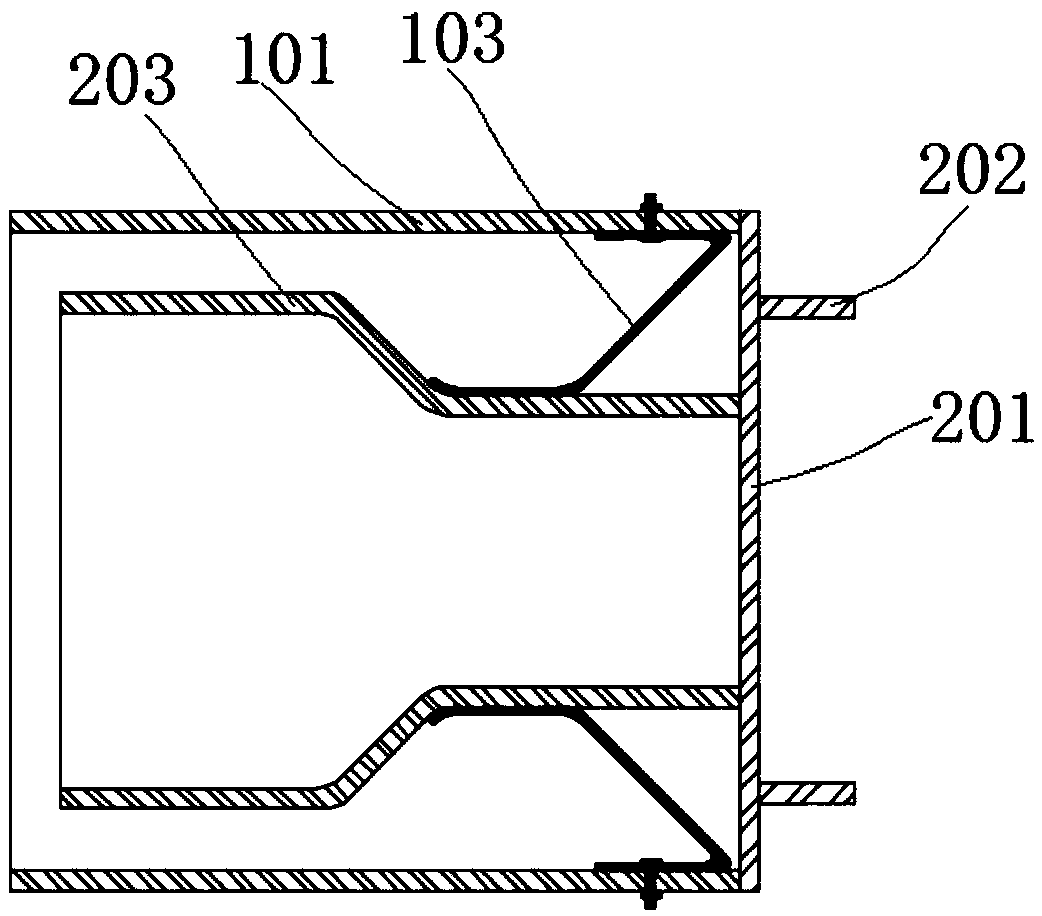

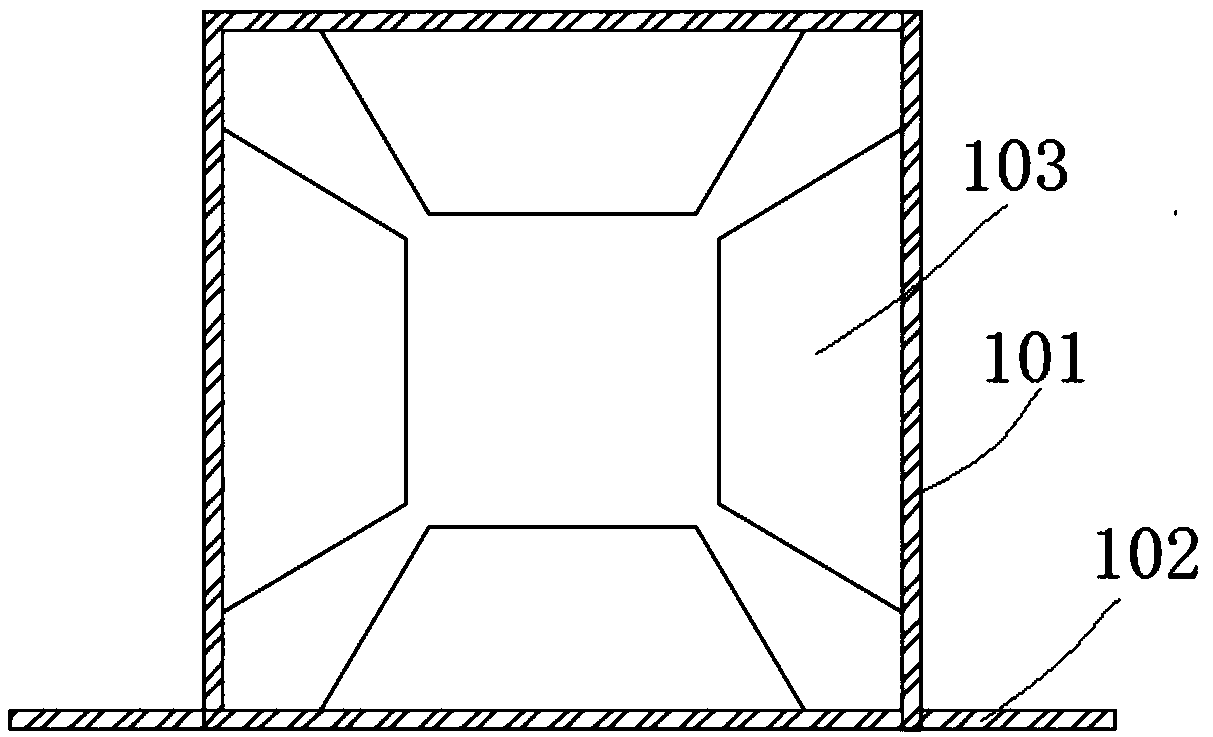

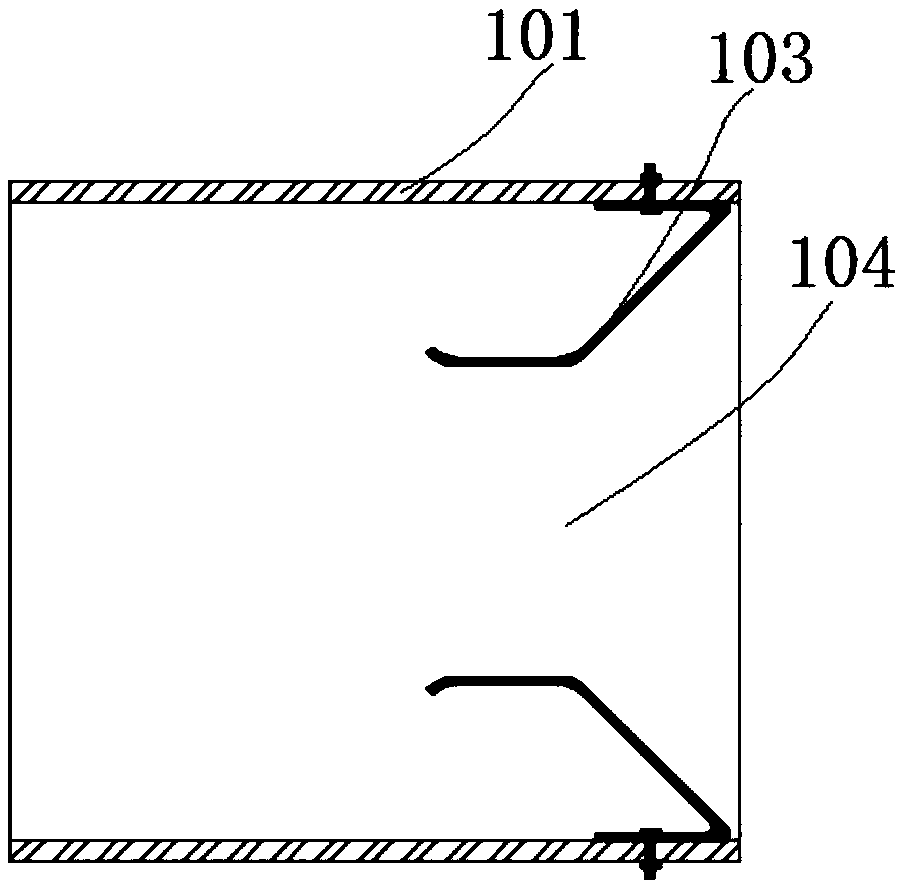

[0032] combine figure 1 , figure 2 , image 3 and Figure 4 , a plug-in structure for connecting an integral light steel wall panel and a steel frame structure in this embodiment includes a plug and a socket, and the socket includes a hollow square box 101 and a first A mounting plate 102, the first mounting plate 102 is fixed on the side of the square box 101, and a shrapnel 103 is arranged around one end of the square box 101, and the surrounding shrapnel 103 forms an elastic bayonet 104; The second mounting plate 201 on the steel frame structure, the reinforcing plate 202 fixed between the back side of the second mounting plate 201 and the steel frame structure, and the clamping block 203 fixed on the front of the second mounting plate 201 The end of the clamping block 203 is an enlarged section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com