Washing additive box and washing machine

An additive and washing machine technology, applied in the field of washing machines, can solve the problems that the capacity of the washing additive box cannot be too large, the washing additive box is frequently taken out, the washing additive box is limited, etc., and achieves the effects of simple structure, high reliability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

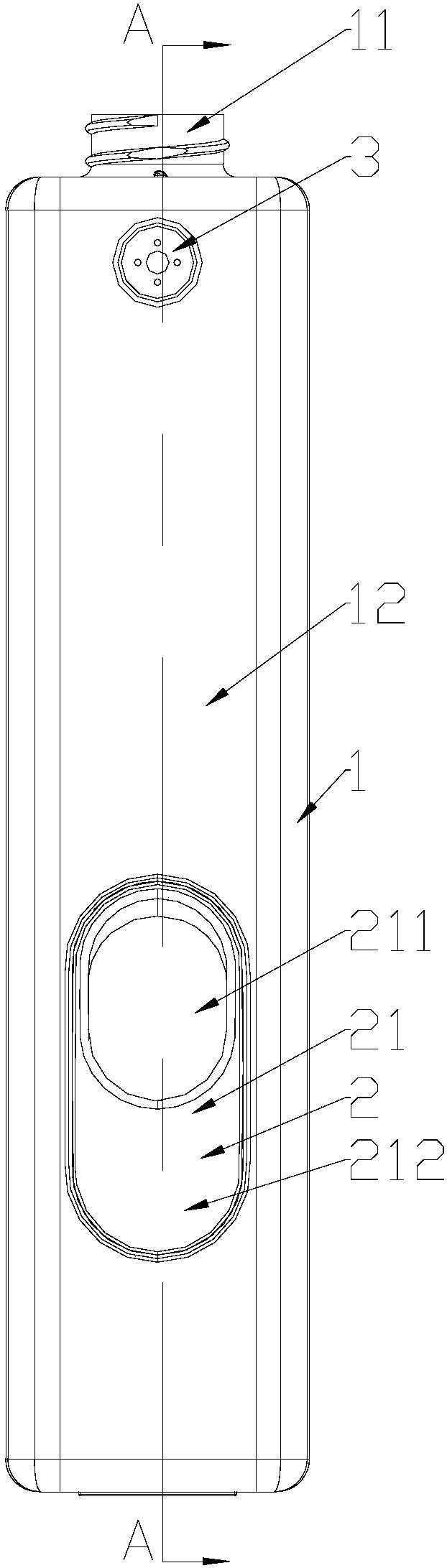

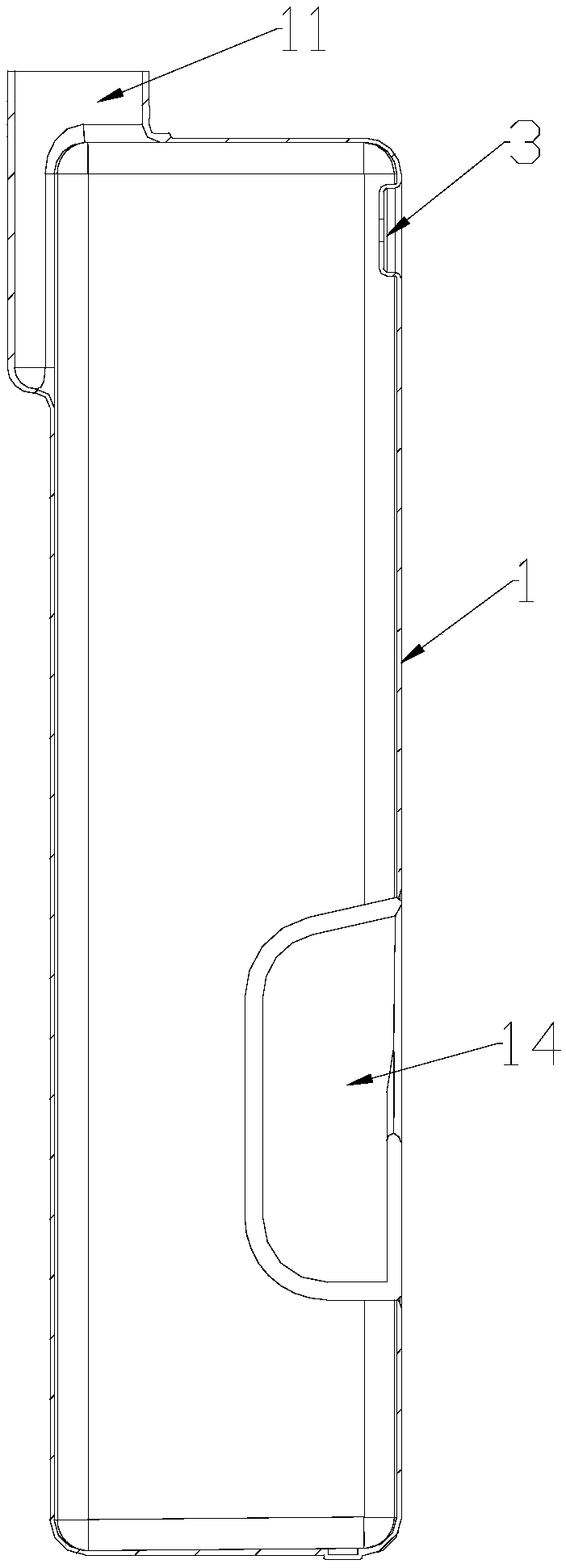

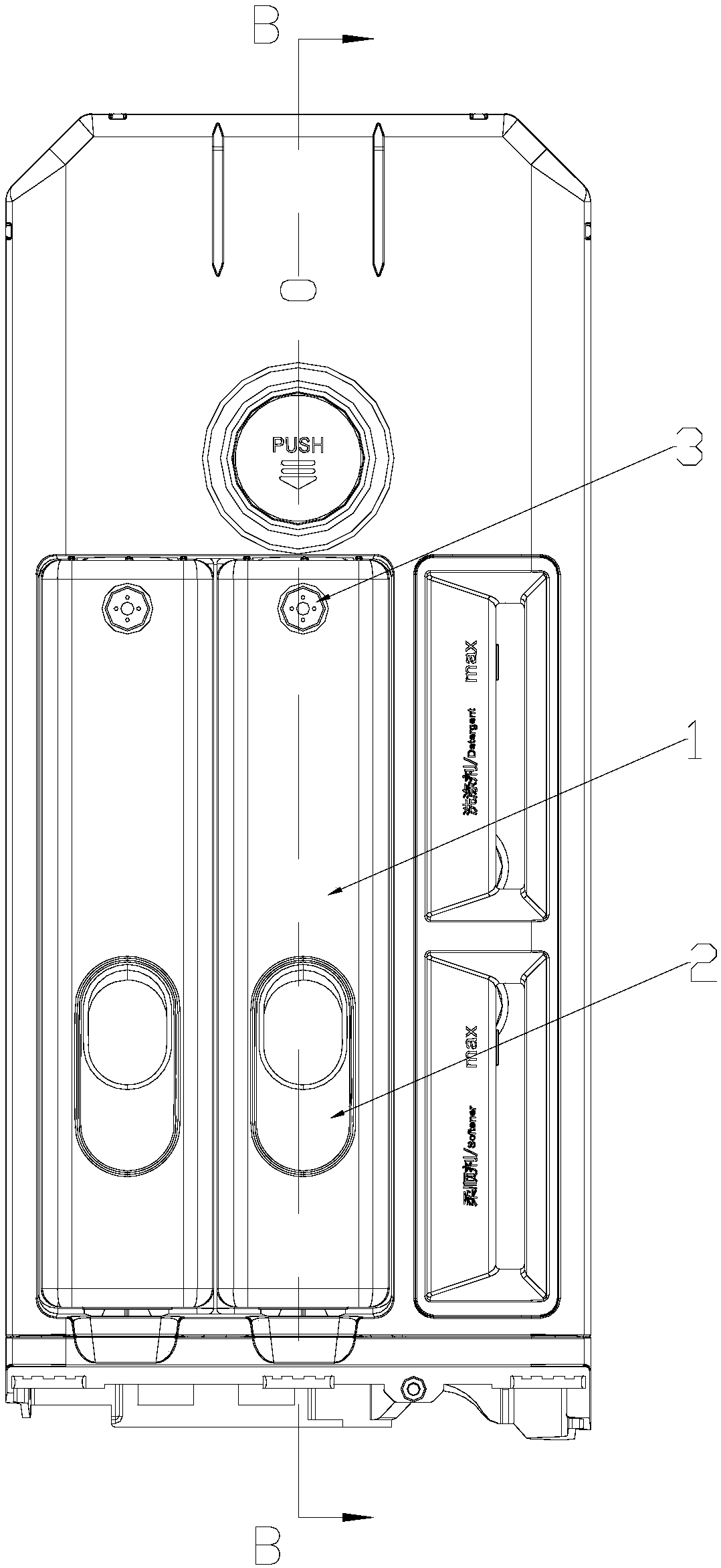

[0068] Such as Figure 1-6 As shown, in this embodiment, a washing additive box includes a box body 1, the box body 1 is detachably arranged in the washing additive box installation cavity on the washing machine, and the box body 1 is provided with a washing additive box to facilitate taking out the washing additive box. The take-out structure of the box, the take-out structure includes a handle structure 2 arranged on the box body 1 .

[0069] A concave cavity 14 is provided on the upper surface 12 of the box body, and the concave cavity 14 is a cavity formed by indenting from top to bottom on the upper surface 12 of the box body, and the handle structure 2 is arranged in the concave cavity 14 .

[0070] The handle structure 2 includes an upper cover 21 covering part of the opening of the concave cavity 14, the lower part of the upper cover 21 is a cavity for the handle, and the other part of the opening and the cavity for hand / finger insertion into the handle cavity. The ha...

Embodiment 2

[0076] Such as Figure 1-6 As shown, in this embodiment, a washing additive box includes a box body 1, the box body 1 is detachably arranged in the washing additive box installation cavity on the washing machine, and the box body 1 is provided with a washing additive box to facilitate taking out the washing additive box. The take-out structure of the box, the take-out structure includes a handle structure 2 arranged on the box body 1 .

[0077] Compared with Embodiment 1, the difference is that the handle structure 2 also includes a side wall 22 and a lower surface, and a handle cavity is formed between the side wall 22 and the upper and lower surfaces; the shape and size of the side wall 22 are uniform. Matches with the side wall 22 of the cavity 14 .

Embodiment 3

[0079] Such as Figure 7-9 As shown, in this embodiment, a washing additive box includes a box body 1, the box body 1 is detachably arranged in the washing additive box installation cavity on the washing machine, and the box body 1 is provided with a washing additive box to facilitate taking out the washing additive box. The take-out structure of the box, the take-out structure includes a handle structure 2 arranged on the box body 1 .

[0080] In this embodiment, the handle structure 2 is arranged on the side surface 13 of the box body, which is a handle cavity 23 on the side surface 13 of the box body that is recessed toward the inside of the box body 1. Preferably, the handle structure 2 is arranged on On the box side 13 opposite to the liquid outlet 11 .

[0081] The clasp hand cavity 23 includes a clasp hand cavity 23 force application surface 231 for fingers / hands to apply force to take out the detergent additive box / assistantly take out the detergent additive box, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com