a diaphragm spring

A diaphragm type, diaphragm technology, applied in leaf springs, springs, springs/shock absorbers, etc., can solve problems such as up and down bumps, circuit board scratches, wheel electrodes unable to rotate, etc., to ensure stability, prevent Caton, the effect of ensuring good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

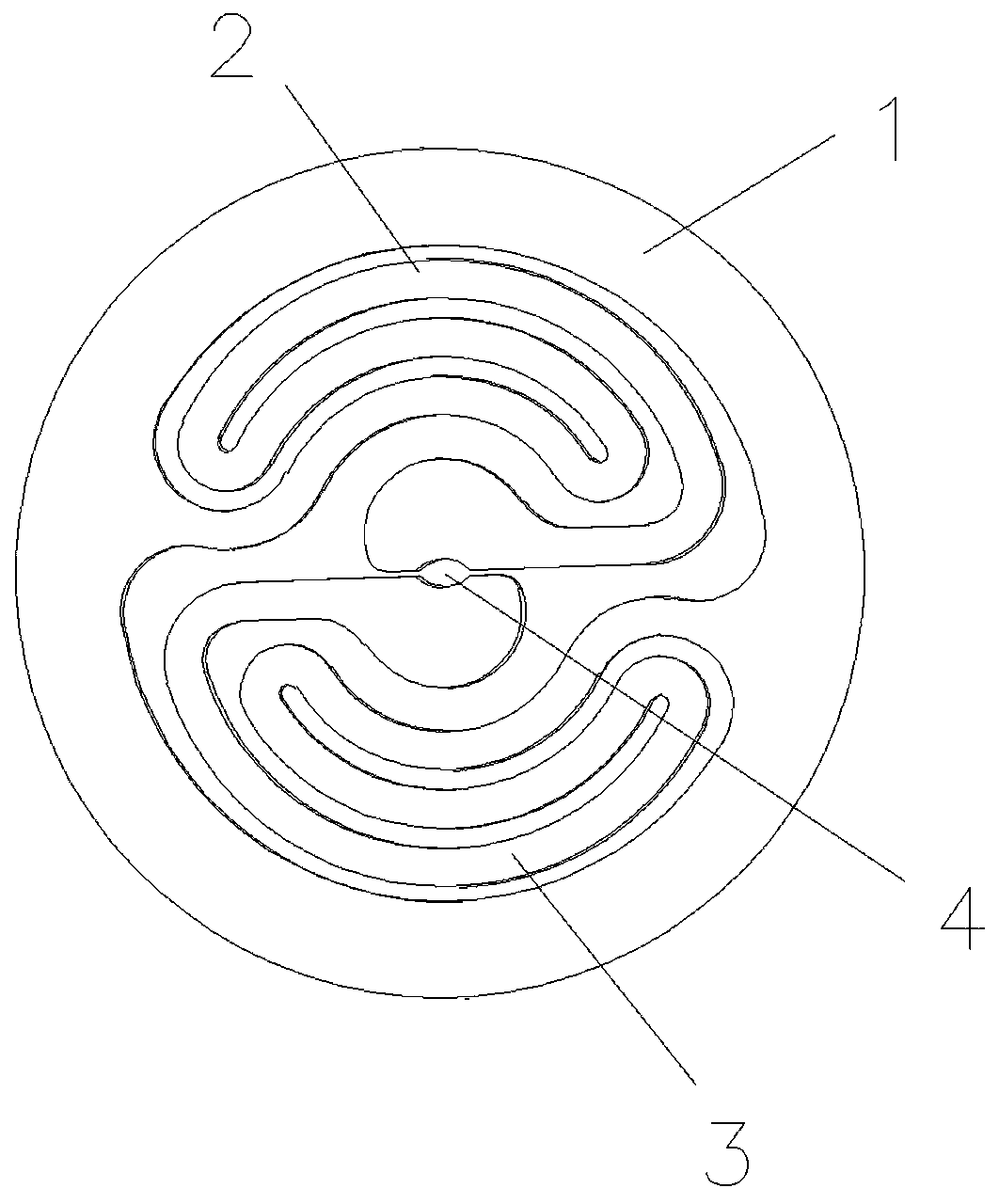

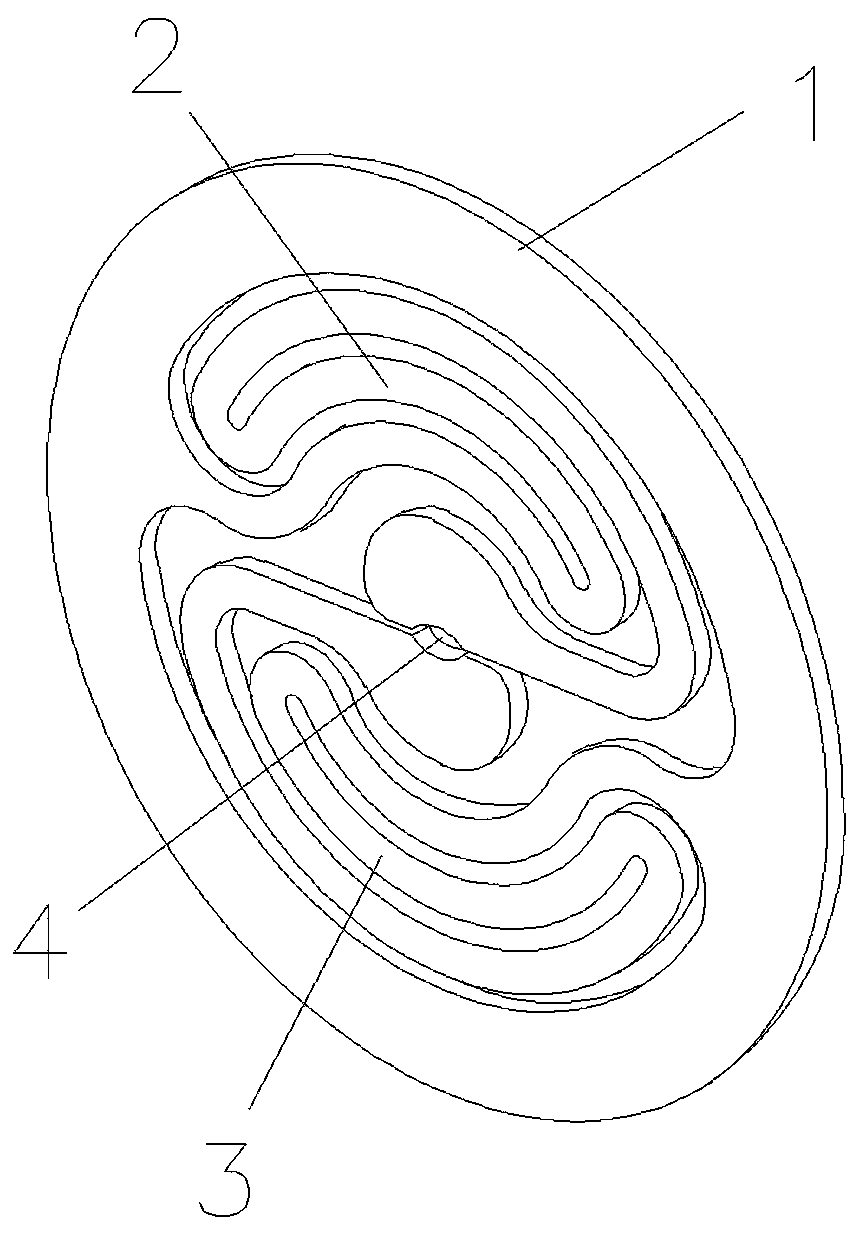

[0015] combine figure 1 and figure 2 As shown, the present invention provides a diaphragm spring, including a contour diaphragm 1, and the contour diaphragm 1 is provided with an elastic deformation part, and the elastic deformation part includes a first elastic rib 2 and a second elastic rib that are reversely symmetrical. Bar 3, the two elastic ribs are in a curved shape, one end of the two elastic ribs is respectively connected to the contour diaphragm, and the other end of the two elastic ribs touches at the center of the contour diaphragm to form an assembly hole 4; assembly The hole 4 can be matched with the shaft of the wheel electrode; the contour diaphragm 1 and the two elastic ribs are an integrated structure.

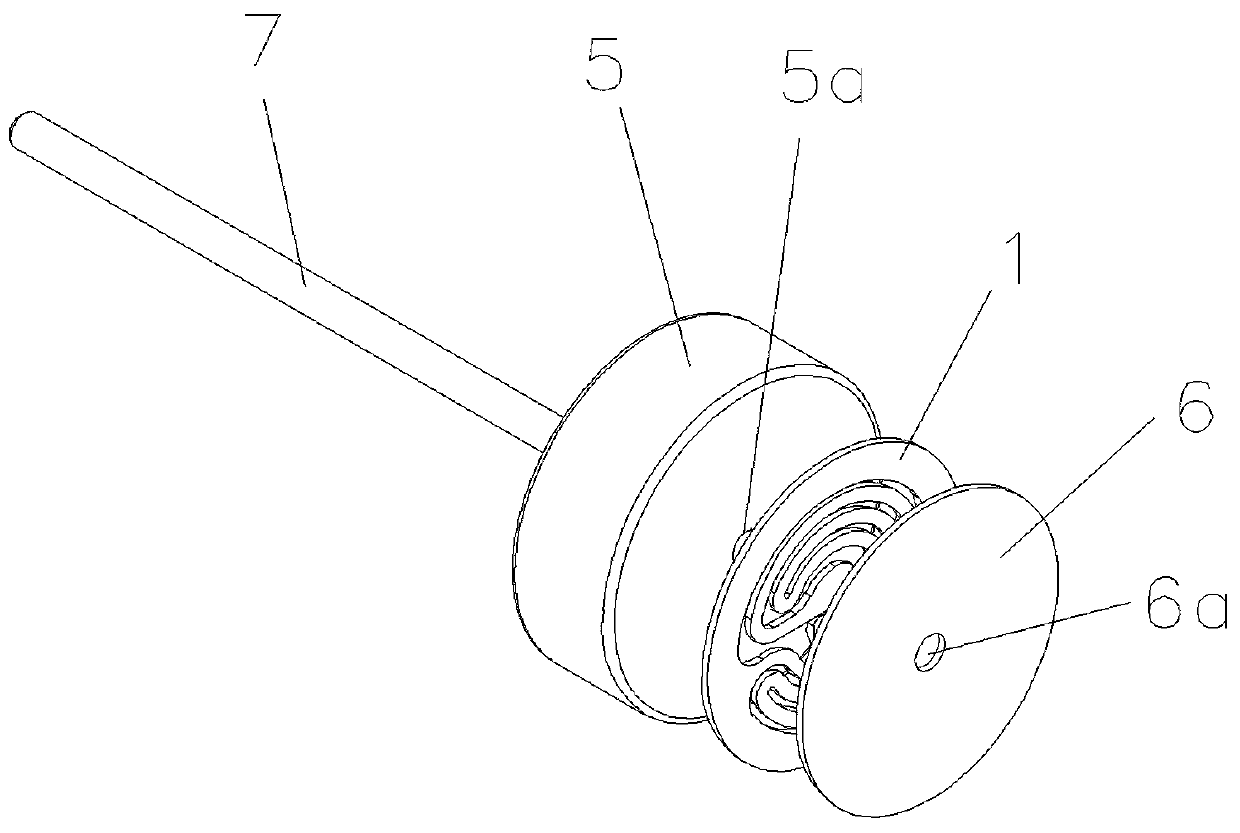

[0016] combine image 3 As shown, when in use, the outer side of the diaphragm spring is welded to the wheel electrode 5, and the diaphragm spring and the wheel electrode 5 are arranged concentrically. In order to prevent the elastic ribs from bending in t...

Embodiment 2

[0019] combine Figure 4 As shown, the present invention provides a diaphragm spring, comprising the same profile diaphragm 1 as in Embodiment 1, and an elastic deformation part is arranged in the contour diaphragm 1, and the elastic deformation part includes a spiral elastic rib 8, elastic The outer end of the rib 8 is connected with the profile diaphragm, and the inner end of the elastic rib 8 is provided with a mounting piece 9, and the mounting plate 9 is provided with an assembly hole 10 concentric with the profile diaphragm, and the assembly hole 10 can be connected with the wheel type. The shaft 6 of the electrode forms a fit; the contour membrane, the elastic rib 8 and the mounting piece 9 are of an integrated structure. The installation and use method of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com