Dry-type transformer high-pressure casting body and casting tool for casting tapping terminal of same

A dry-type transformer and terminal technology, which is applied in the field of transformers, can solve problems such as cracking of the convex table surface, and achieve the effect of ensuring good contact and solving the cracking of the convex table surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

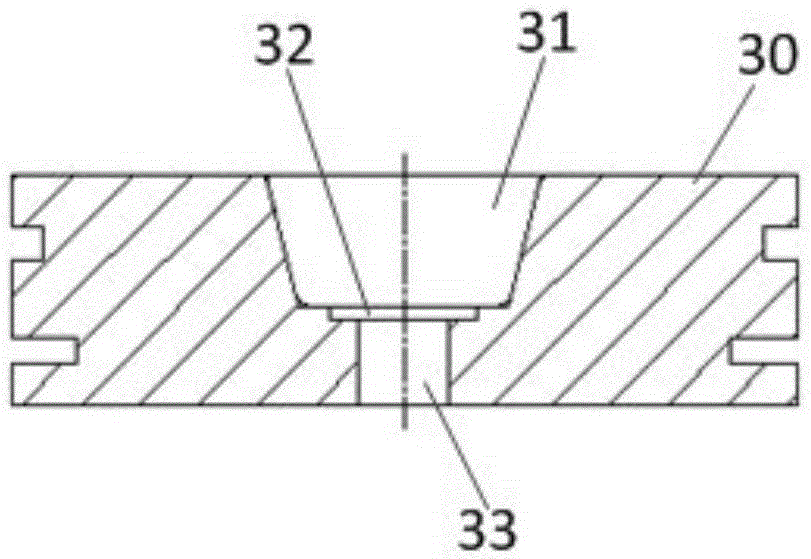

[0018] Such as Figure 3-4 As shown, the present invention provides a dry-type transformer high-voltage coil tap terminal casting tool, including a tool body 30, and the tool body 30 is provided with a notch 31 for the tap terminal 40 to be inserted into, and the tool body 30 is in the slot The bottom of the port 31 is provided with a positioning groove 32 for positioning the tap terminal 40, and a through threaded hole 33 is also provided between the positioning groove 32 and the back side of the tooling body 30; when the tap terminal 40 to be poured is inserted into the groove When opening 31 , the bottom is positioned by positioning groove 32 and tightly connected with fastening bolt 34 penetrating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com