Rectangular smoothing connector testing tool

A testing tooling and rectangular filtering technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of large number of input equipment, low efficiency, long detection time, etc., to ensure good contact, facilitate rapid positioning, and shorten detection time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

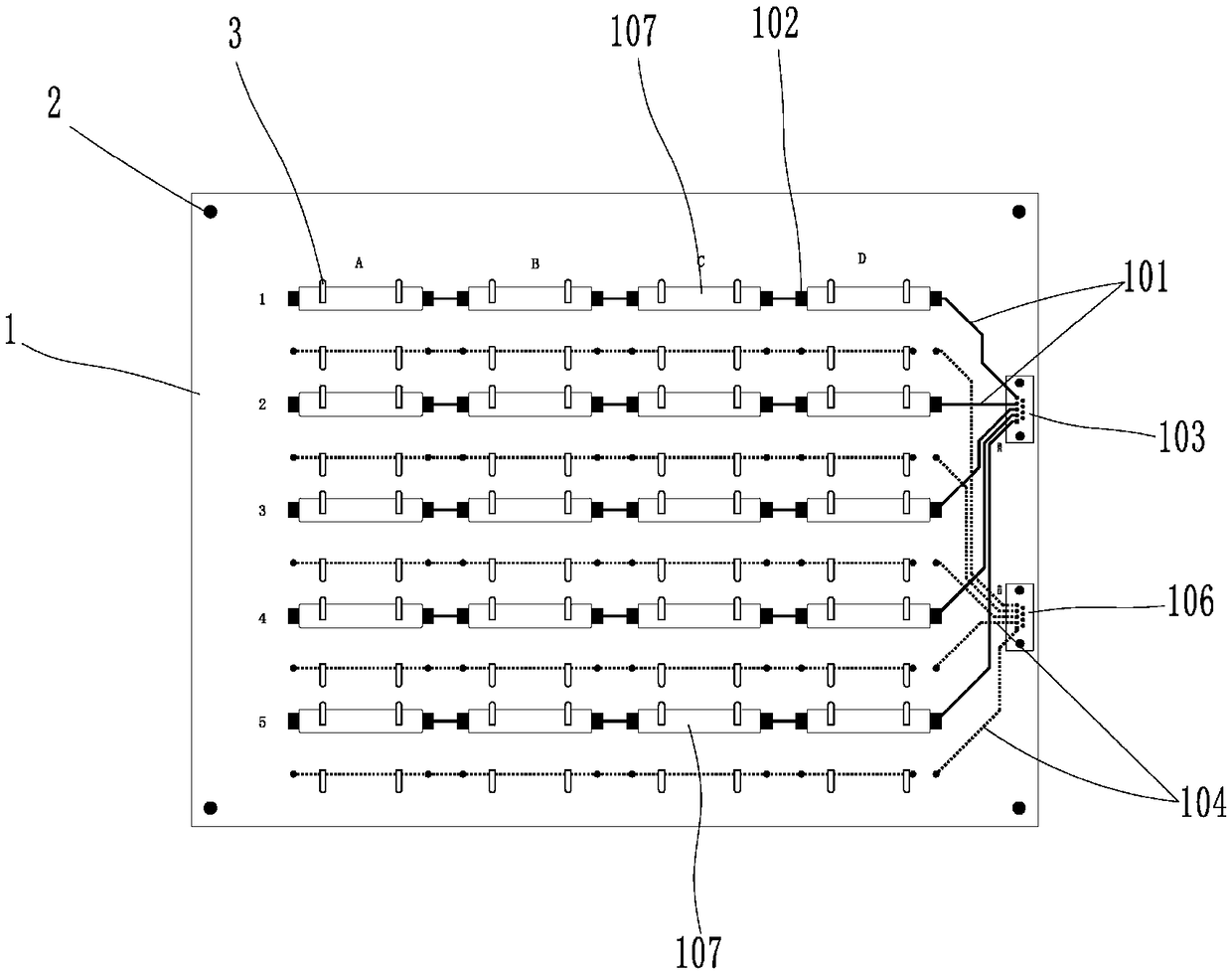

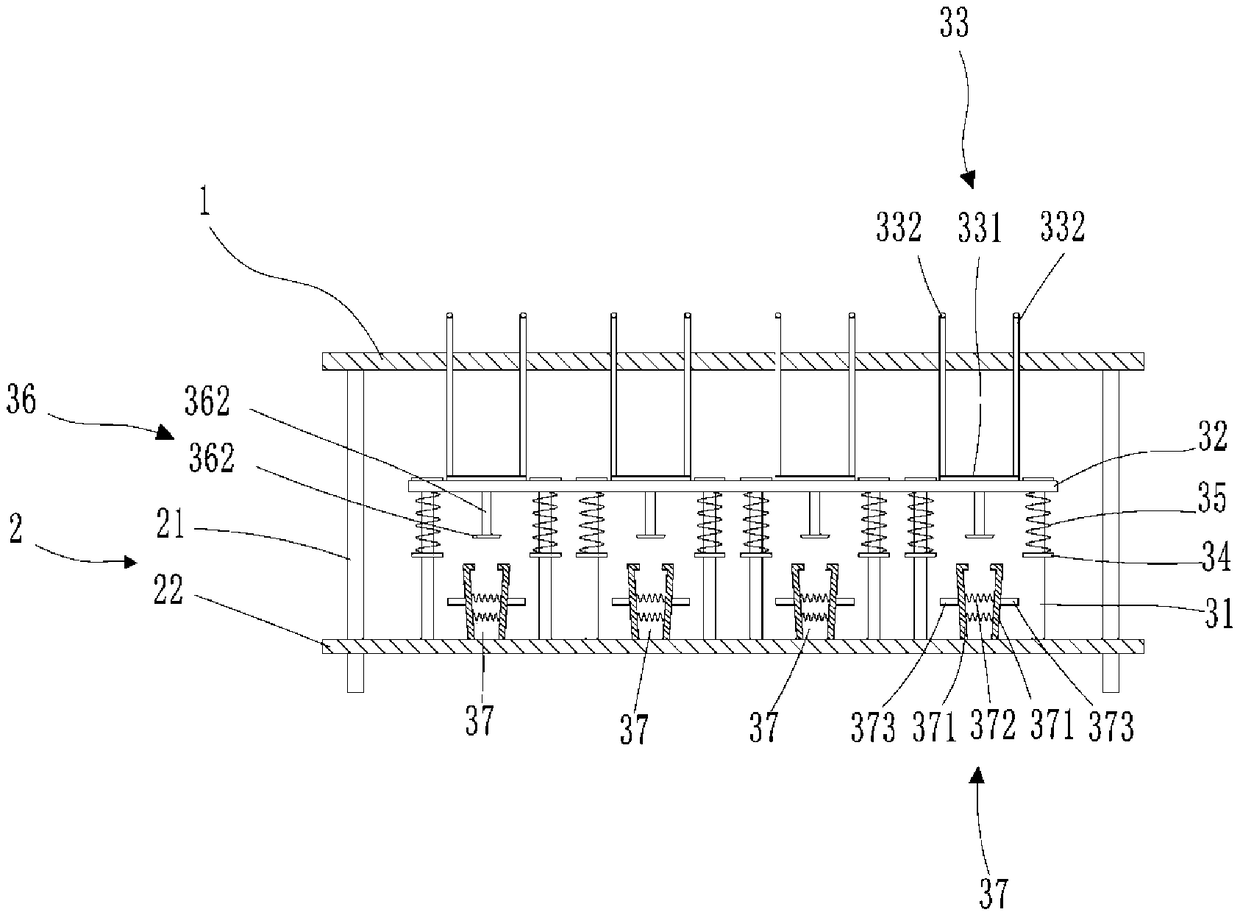

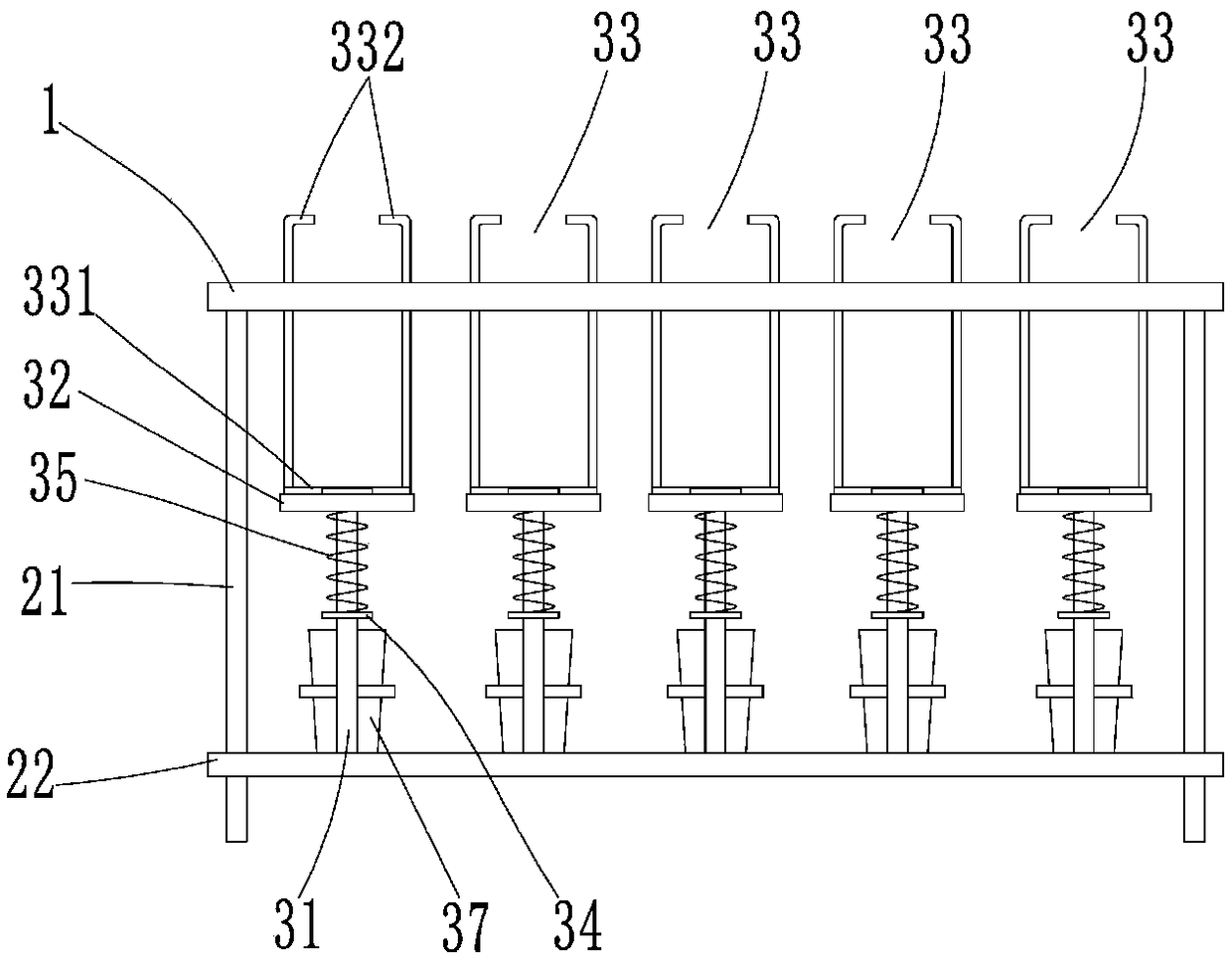

[0024] Such as Figure 1 ~ Figure 3 As shown in the present invention, a rectangular filter connector test tool, a double-sided circuit board 1, five positive wires 101 are arranged on the front of the double-sided circuit board 1, and each positive wire 101 is provided with 8 first pads 102, the starting ends of 5 positive wires 101 are connected to the positive connector 103; the back of the double-sided circuit board 1 is provided with 5 negative wires 104 offset from the positive wires 101, and each negative wire 104 8 second pads 105 aligned with the first pads 102 are arranged on the top, and the initial sections of the 5 negative wires 104 are connected to the negative terminal 106, and the positive terminal 103 and the negative terminal 106 are fixed on the double-sided The edge position of the circuit board 1; four current-limiting resistors 107 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com