Draught-fan-free cooling tower

A cooling tower, no fan technology, used in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of complex tower structure, high energy consumption, high operating costs, and save The effect of fan design, reducing energy consumption and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

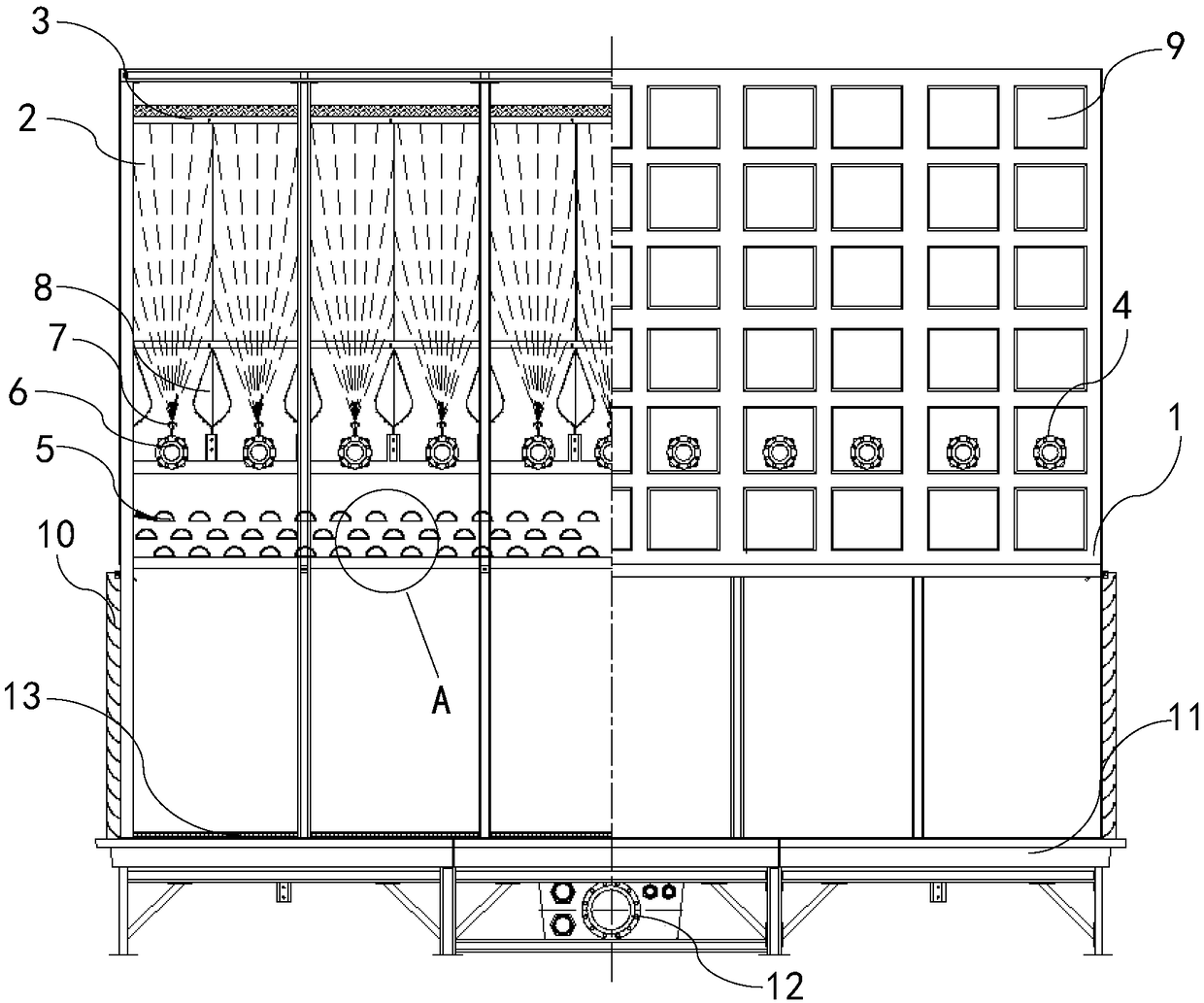

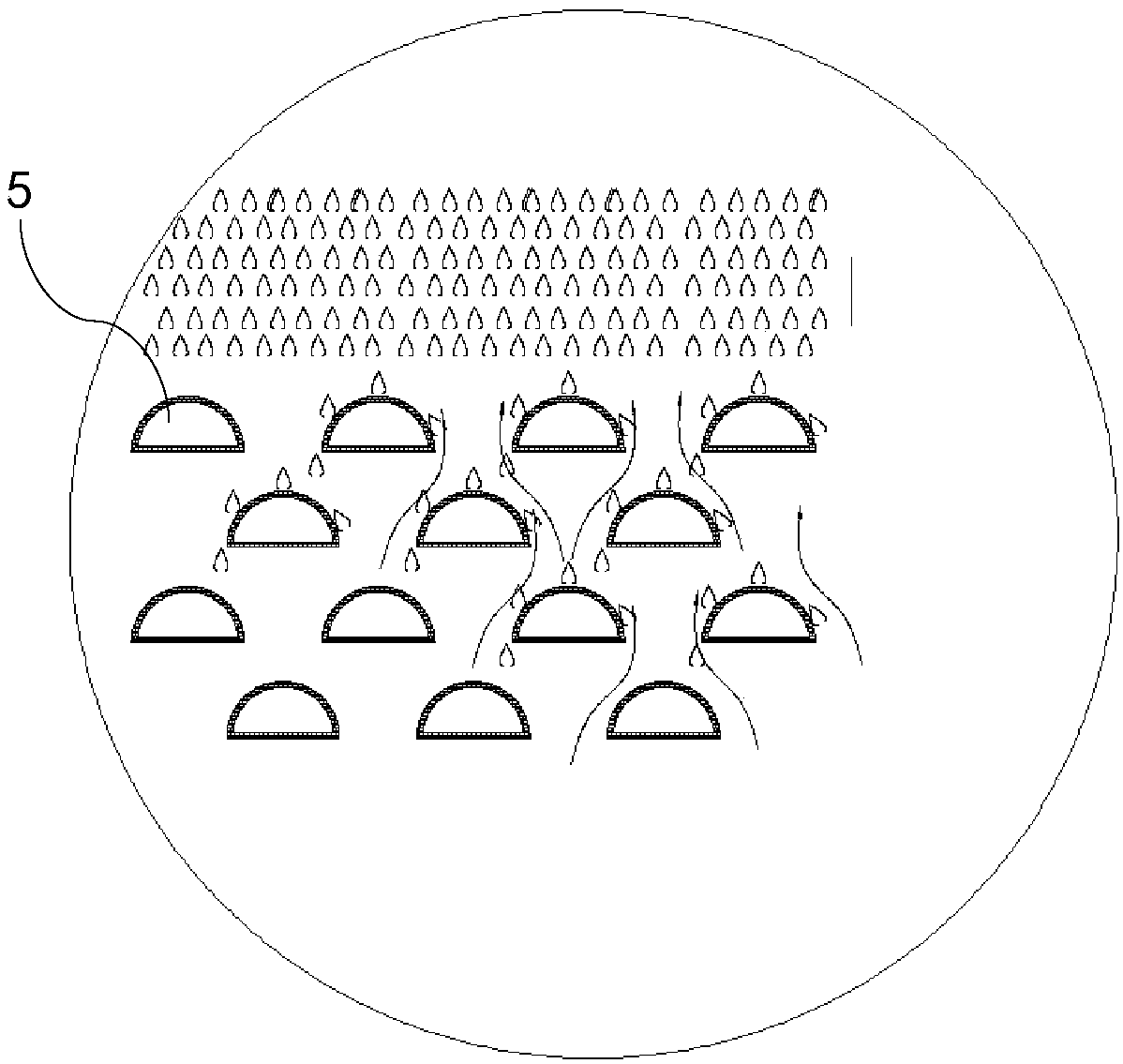

[0018] Please refer to the attached figure 1 , a fanless cooling tower provided by the present invention, which includes a tower body 1, the tower body 1 is provided with an air inlet layer and a heat dissipation layer in sequence from bottom to top, for atomizing the incoming water and spraying it from the top The spray layer, the atomization chamber 2 for containing the atomized water vapor, and the water collector 3 for liquefying the water vapor; the bottom of the wind-inlet layer is provided with a water outlet layer, and the spray layer is provided with a Water connection flange 4.

[0019] Based on the above technical features, the bottom of the tower body 1 is na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com