Micro-pressure pot convenient to use

A pot lid and pot ear technology, applied in the field of kitchen utensils, can solve the problems of thick pot handle, inconvenient handling of pots and utensils, high friction, etc., achieves less possibility of foreign matter entering, ensures smooth left and right sliding, and improves service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

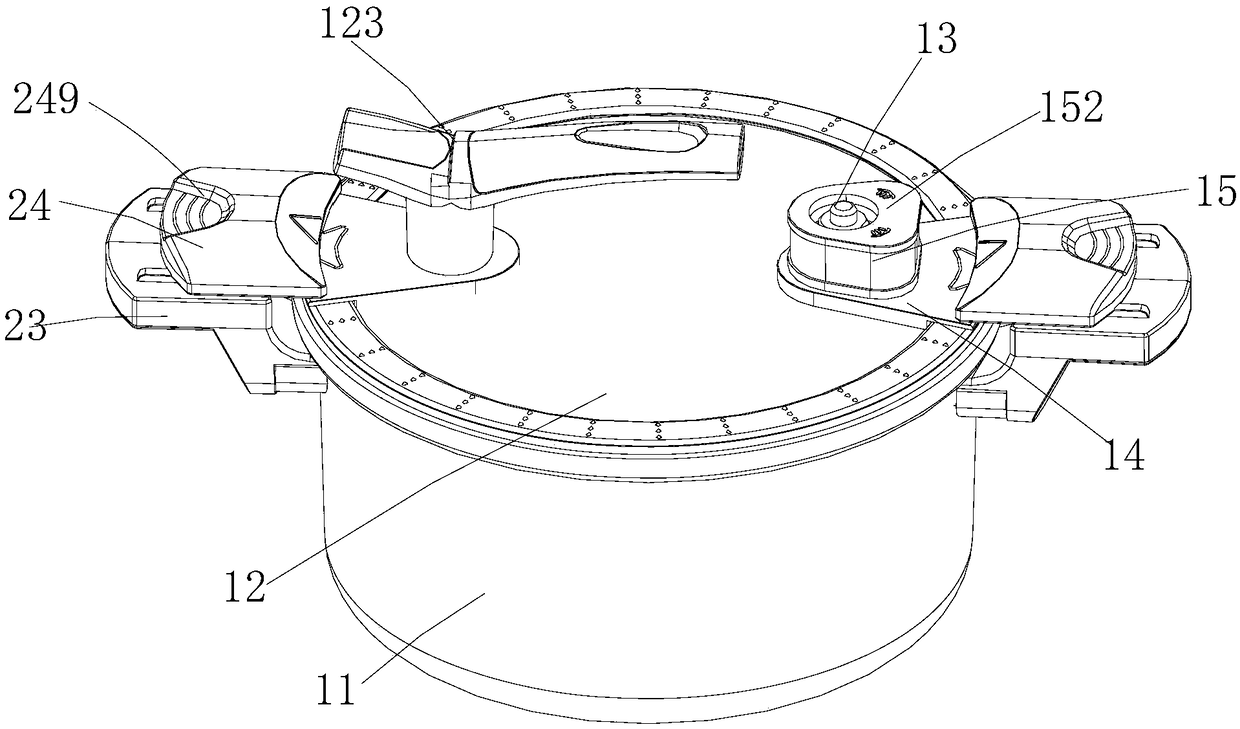

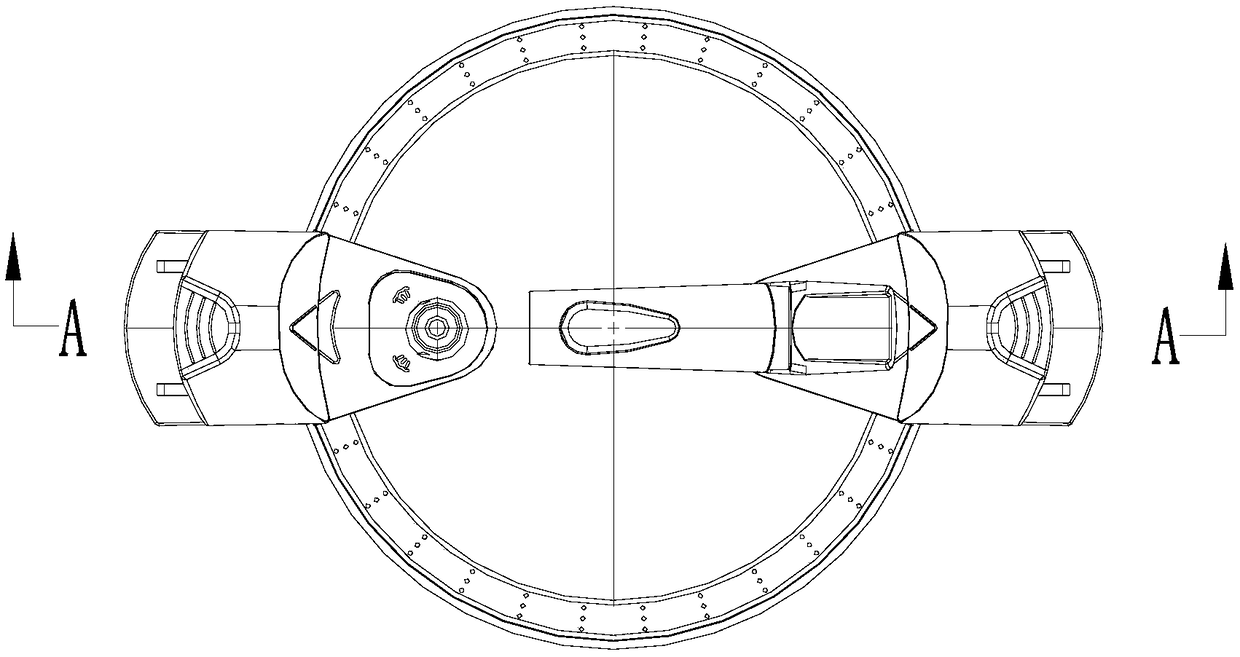

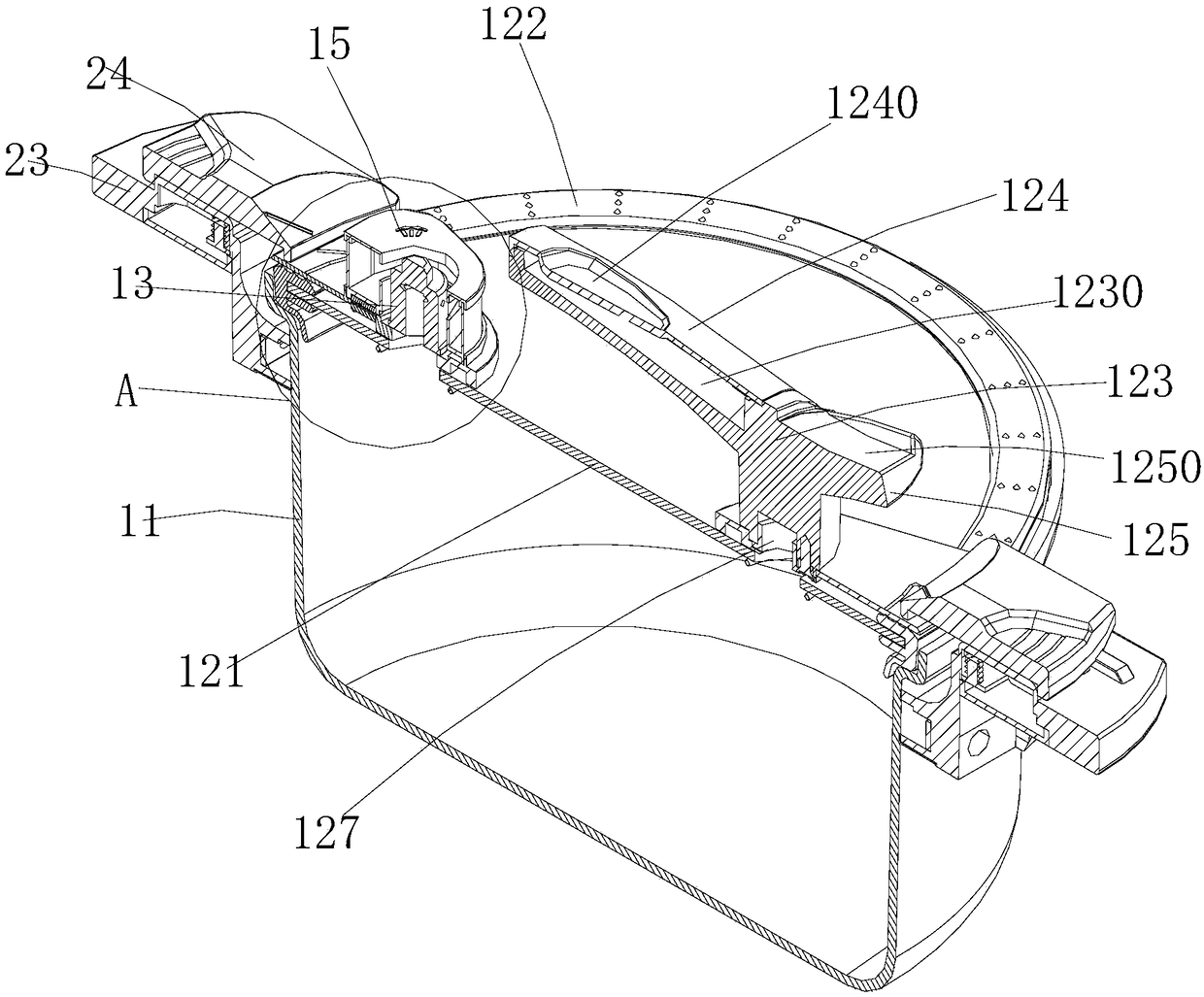

[0042] like Figure 1-7 As shown, a kind of easy-to-use micro pressure cooker comprises a pot body 11, a pot cover 12, an exhaust valve 13 arranged on the pot cover 12, a box body 151 and a pot ear body 23, wherein the pot body 1 is aluminum An alloy pot, the pot body 1 is formed by direct die-casting, and a stepped support portion 110 is provided on the upper end of the pot body 11; the pot cover 12 includes a cover body 121 and a cover ring 122, and the cover body 121 is made of aluminum alloy A circular plate, on the cover 121 is provided with a first opening 1211 for inserting the exhaust valve 13, and a first sealing ring 1213 is provided below the first opening 1211, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com