Polyethylene corrugated pipe and expansion molding process thereof

A molding process and bellows technology, which is applied in the expansion molding process of polyethylene bellows, can solve the problems of increasing the radial direction of the pipe, unable to maintain the hydraulic burst strength of the pipe, etc., to overcome the temperature overshoot, improve the axial shrinkage rate, Effects to avoid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0045] The first preferred embodiment:

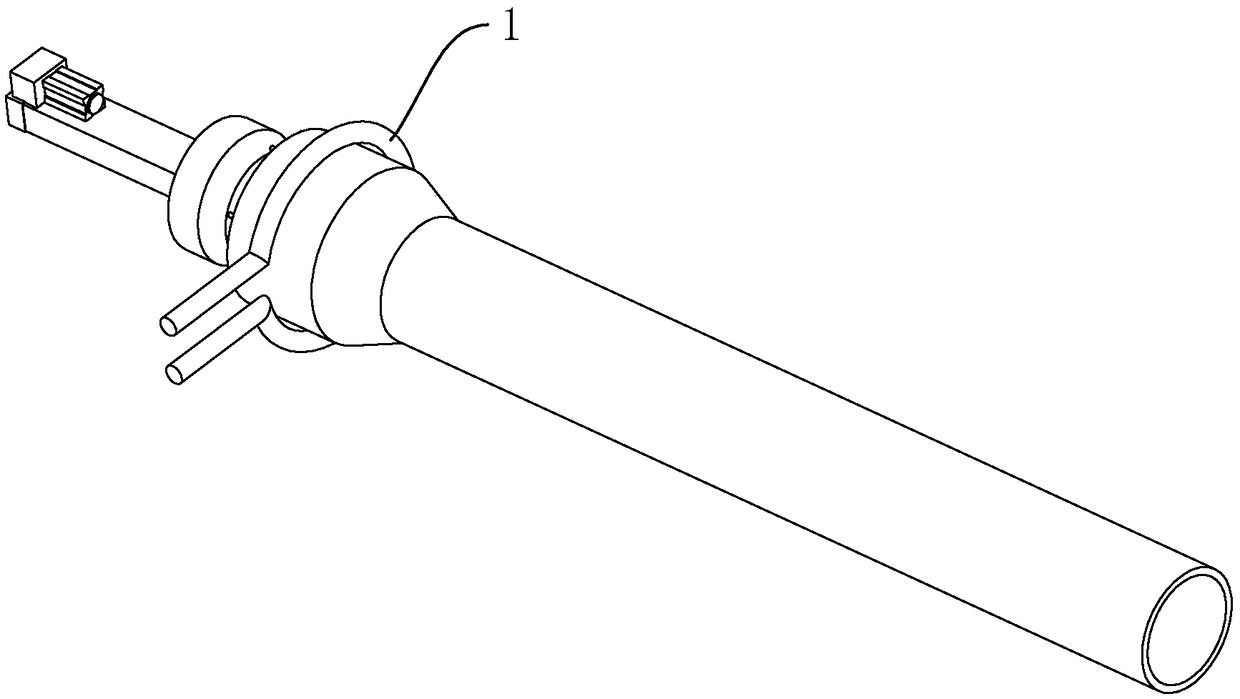

[0046] A polyethylene bellows expansion forming device, such as figure 1 As shown, including the base (not shown in the figure), the base is provided with an annular far-infrared heating component 1 that can be sleeved to the outer ring of the pipe 15 and is spaced from the pipe 15. The annular far-infrared heating component 1 is made of ceramic material. Formed and in the form of a ring structure, the pipe 15 is heated evenly, and the wall deviation of the heat-shrinkable tube will not occur after expansion, and is suitable for the expansion of heat-shrinkable tubes of various specifications.

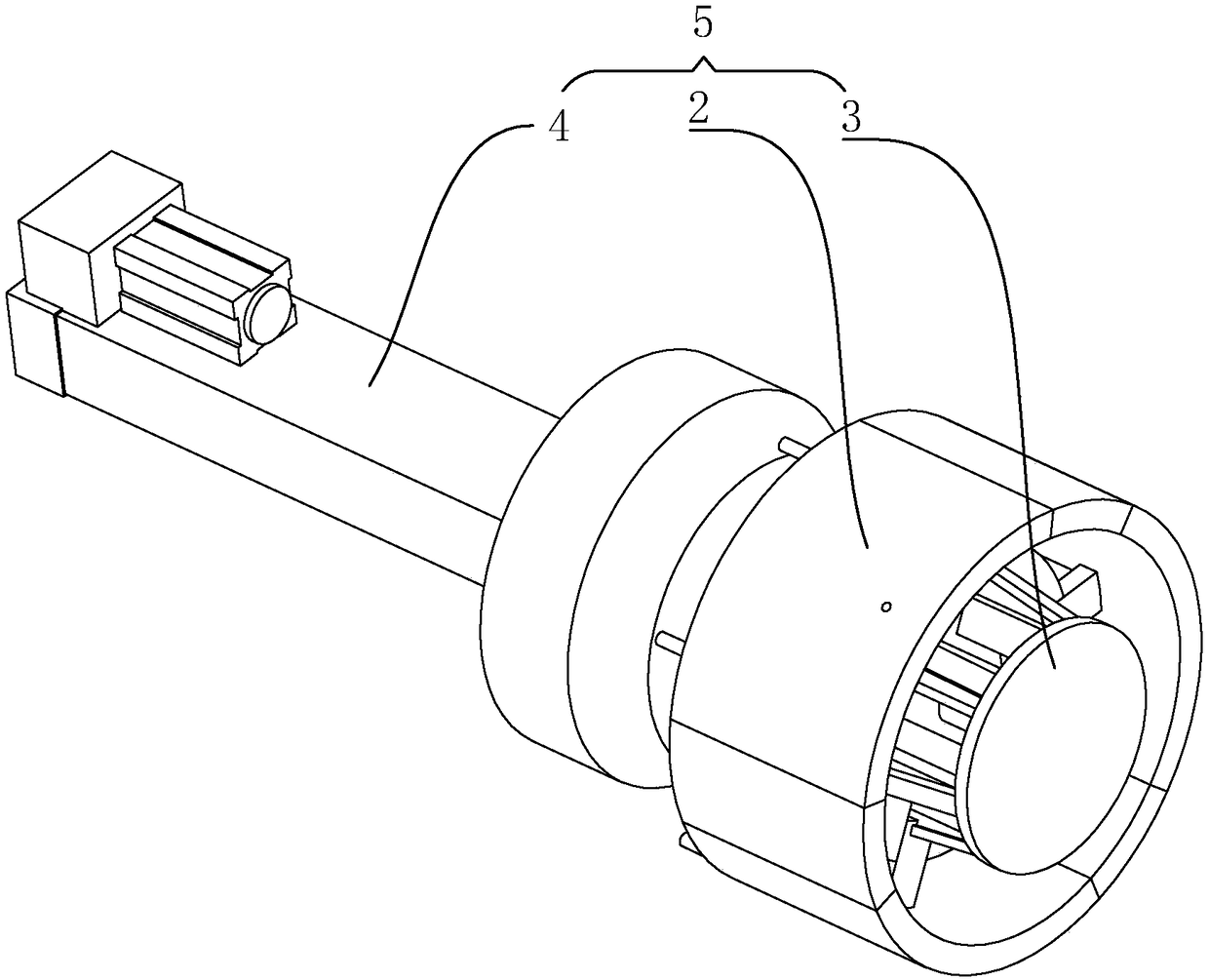

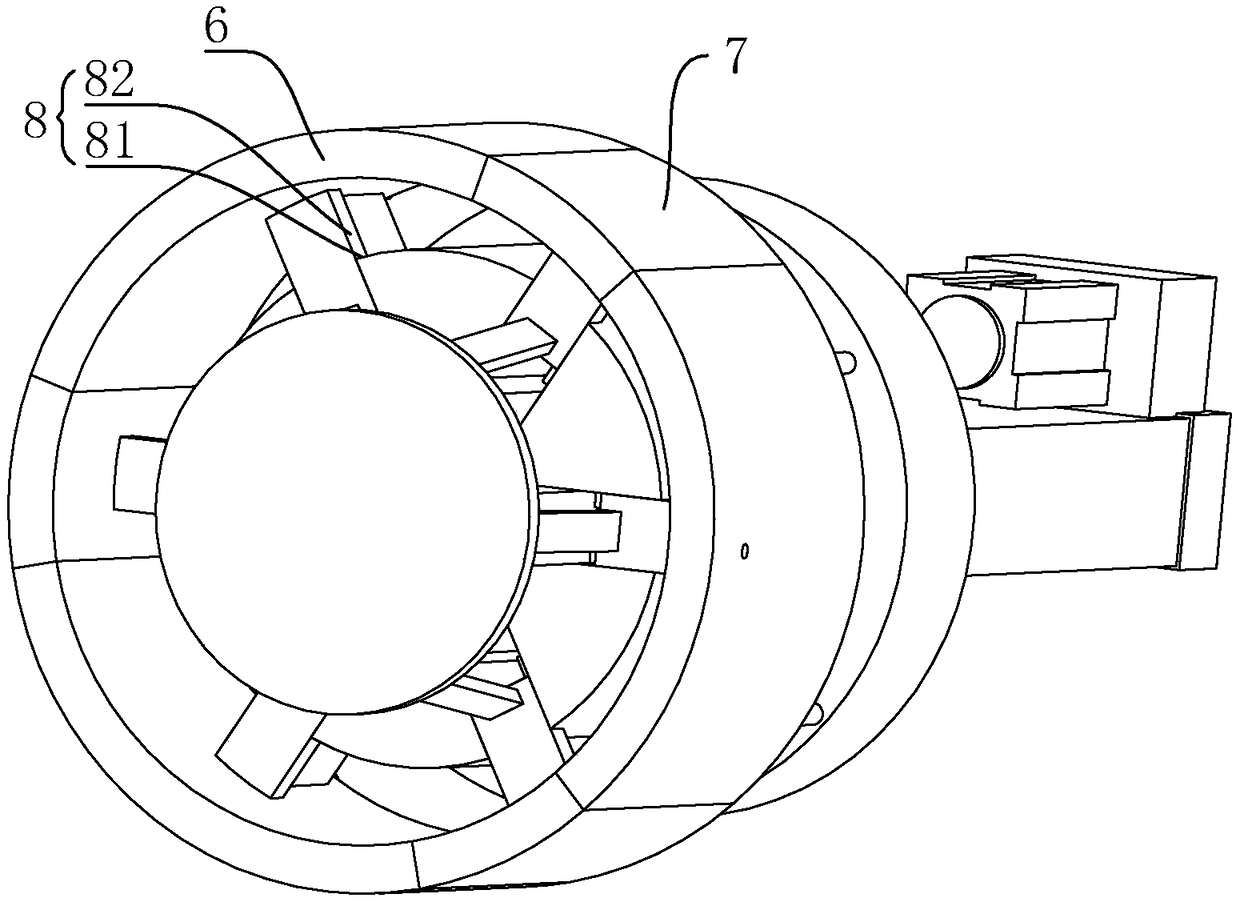

[0047] Such as figure 2 As shown, the base is also provided with a flaring mechanism 5 embedded in the end of the pipe 15. The flaring mechanism 5 includes a flaring part 2 that moves along the radial direction of the pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com