Polyethylene solid wall pipe and its expansion forming device

A technology of forming device and solid-wall pipe, applied in the field of expansion forming device of polyethylene solid-wall pipe, can solve the problems of unable to maintain the hydraulic burst strength of the pipe, increase the radial direction of the pipe, etc., achieve a good axial shrinkage rate, overcome the excessive temperature The effect of precise control of flushing and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] The first preferred embodiment:

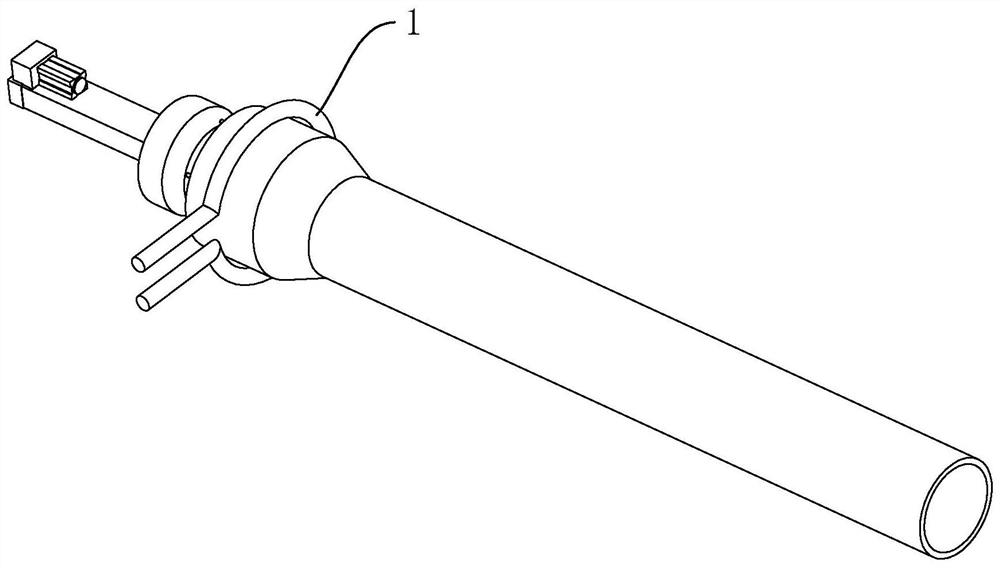

[0041] A kind of expansion forming device of polyethylene solid wall pipe, such as figure 1 As shown, including the base (not shown in the figure), the base is provided with an annular far-infrared heating component 1 that can be sleeved to the outer ring of the pipe 15 and is spaced from the pipe 15. The annular far-infrared heating component 1 is made of ceramic material. Formed and in the form of a ring structure, the pipe 15 is heated evenly, and the wall deviation of the heat-shrinkable tube will not occur after expansion, and is suitable for the expansion of heat-shrinkable tubes of various specifications.

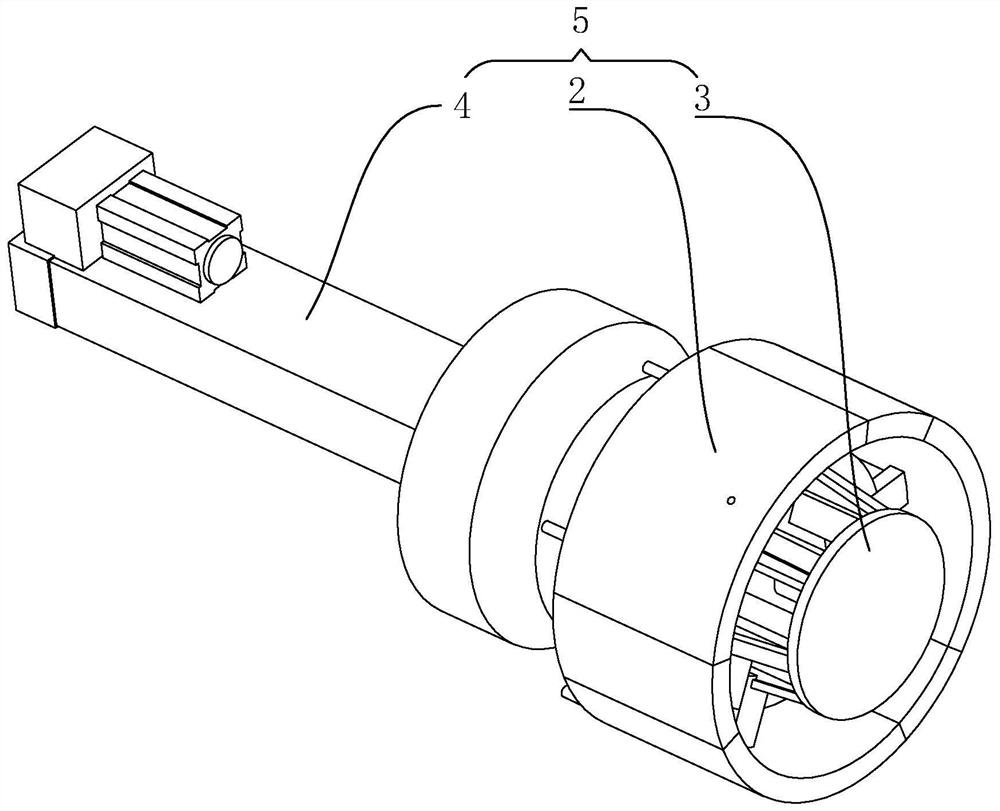

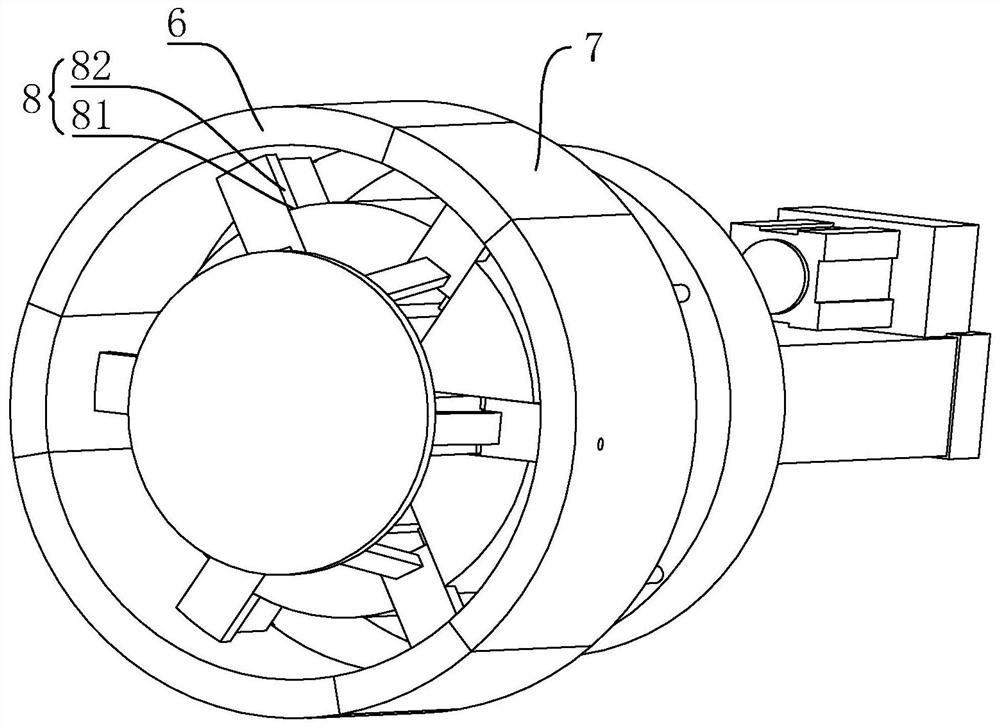

[0042] Such as figure 2 As shown, the base is also provided with a flaring mechanism 5 embedded in the end of the pipe 15. The flaring mechanism 5 includes a flaring part 2 that moves along the radial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com