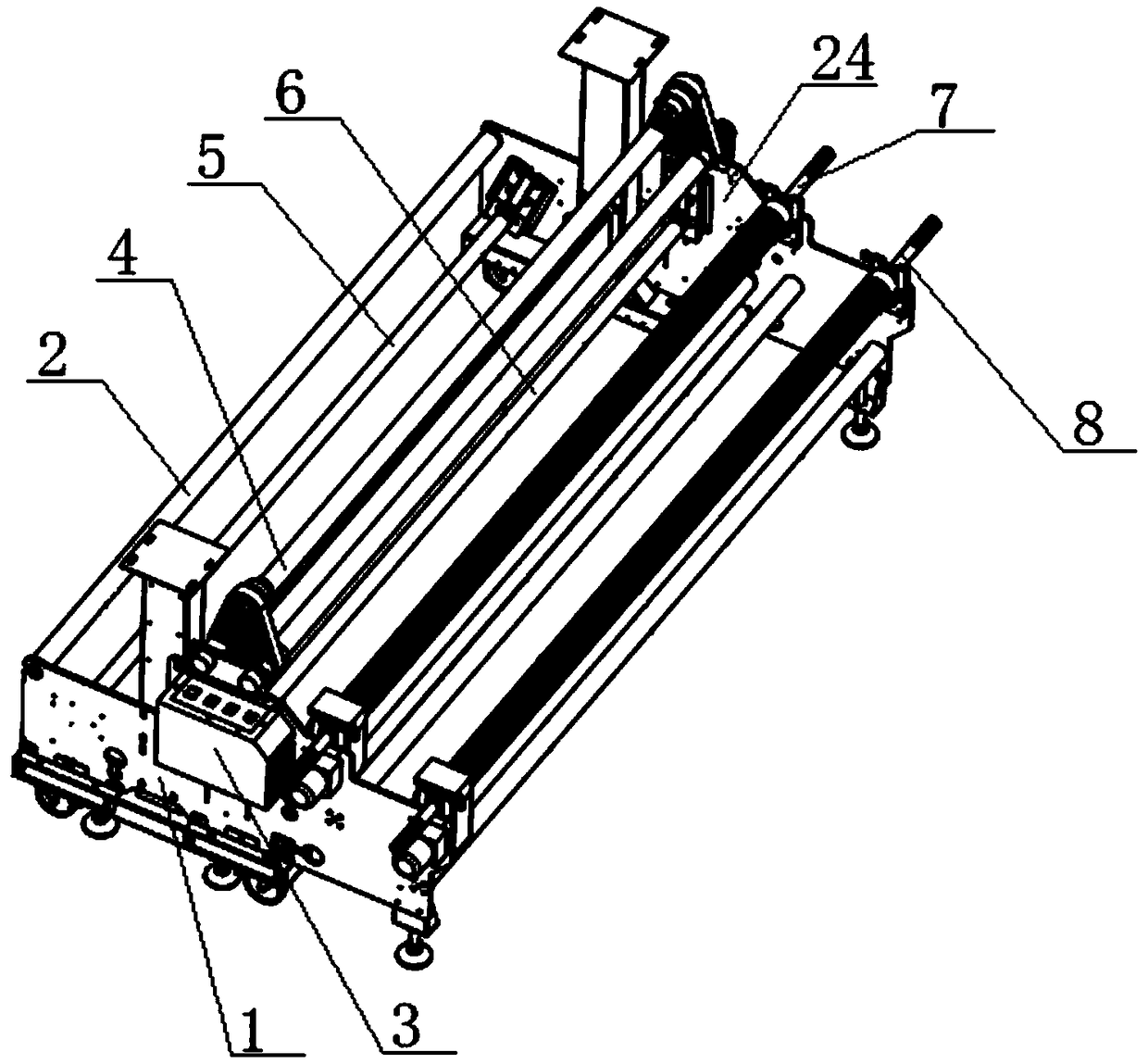

Material collecting and discharging device for ink-jet printer

A technology of inkjet printers and feeding and unwinding materials, applied in printing devices, printing, etc., can solve problems such as pattern scratches, affect the quality of printed products, and poor ink transfer and color development effects, and achieve the effect of avoiding moisture and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

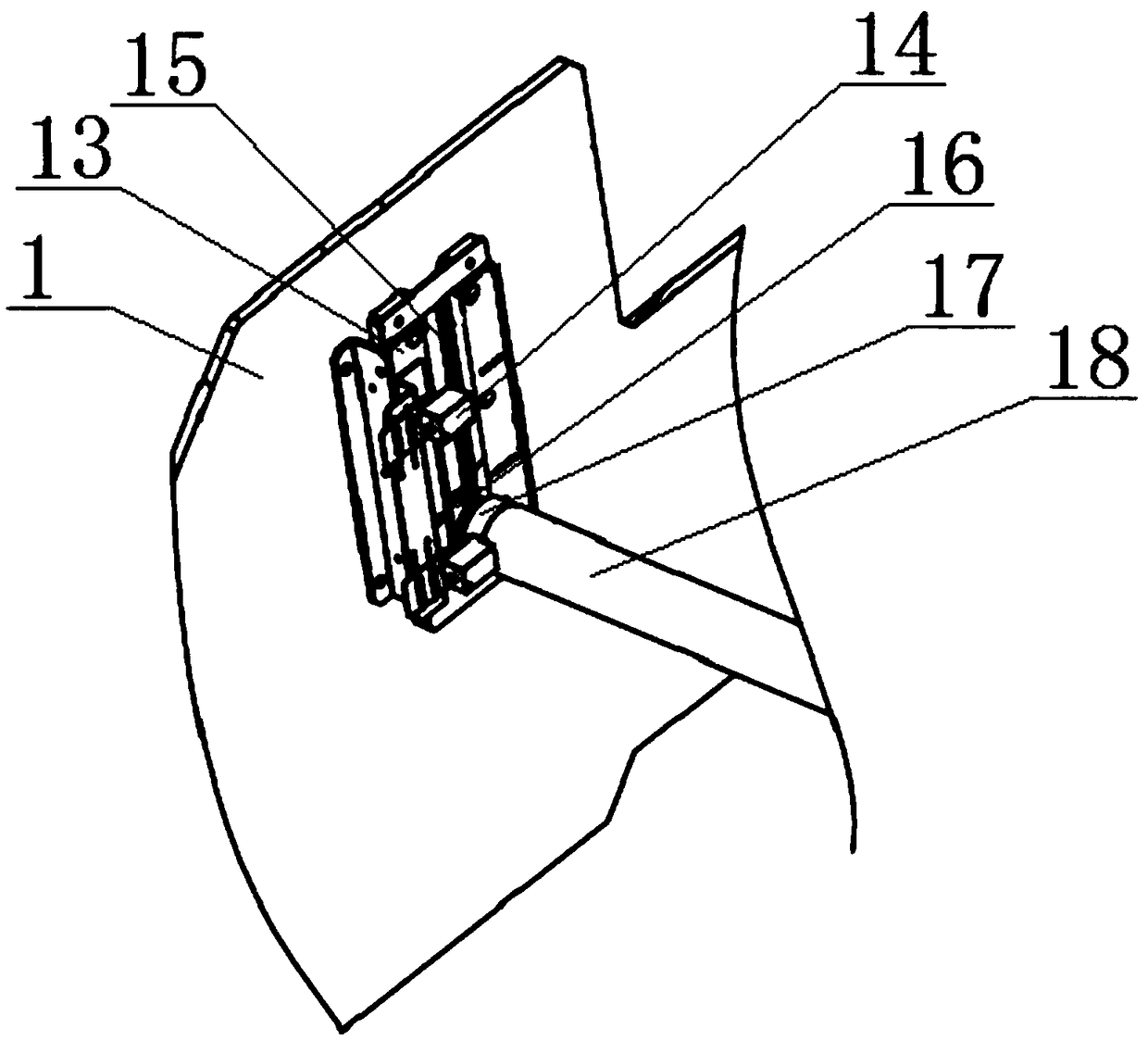

[0024] As a preferred embodiment of the present invention, the rack 15 is meshed with the tension tube gear 16 .

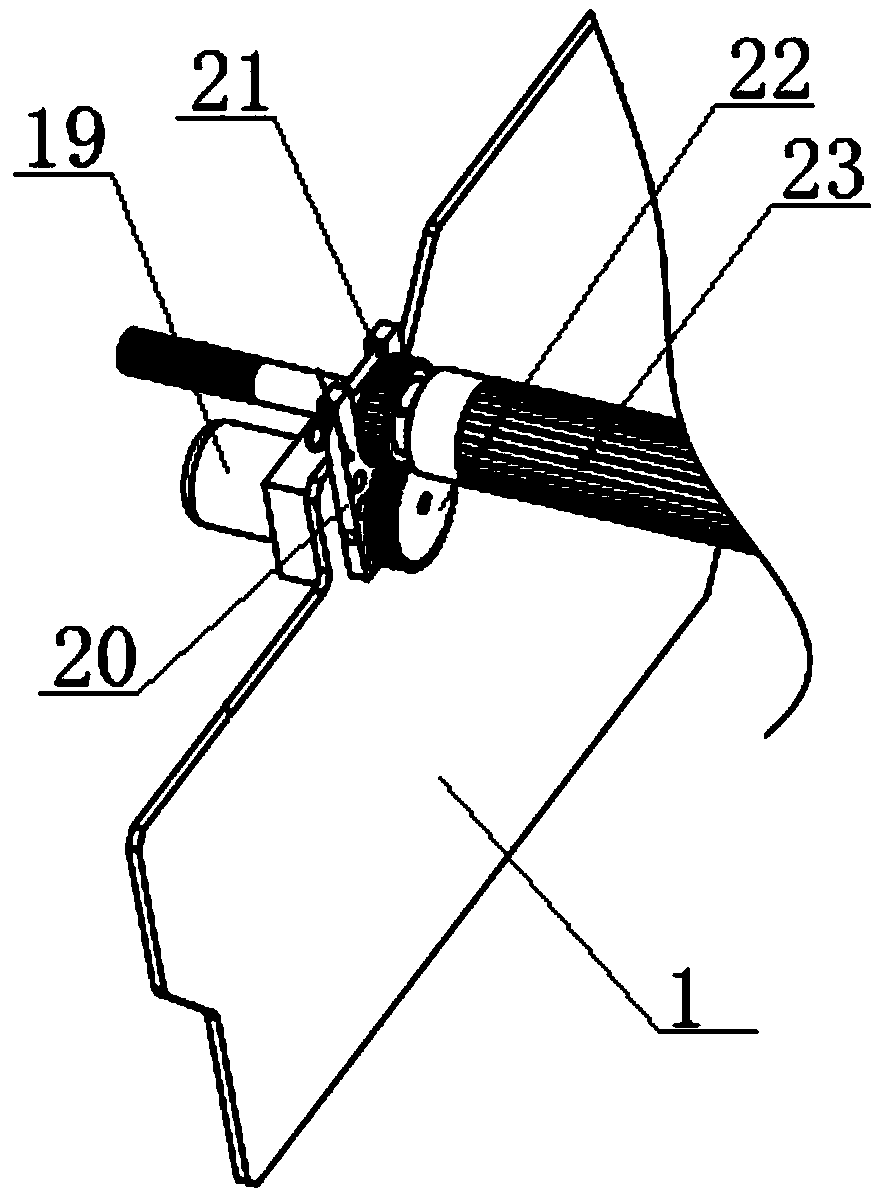

[0025] As a preferred embodiment of the present invention, one end of the inflation shaft 23 is provided with an inflation shaft gear 21 , and the driving motor gear 22 meshes with the inflation shaft gear 21 .

[0026] As a preferred embodiment of the present invention, the controller 3 is respectively connected to the drive motor 19 and the photoelectric switch 14 through a command circuit, and the controller 3 controls the rotation direction and the step of the drive motor 19, and through the photoelectric switch 14 The working position of the tensioning tube 18 is controlled so that the unwinding and paper feeding steps are consistent with the receiving and feeding steps, forming a continuous, stable and reliable feeding and unwinding process.

[0027] As a preferred embodiment of the present invention, the front tension tube assembly 5 has the same structure as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com