A geothermal well wall cleaning device

A technology for cleaning devices and geothermal wells, which is applied in wellbore/well parts, cleaning equipment, earthwork drilling and mining, etc., can solve the problems of low stability of geothermal well wall cleaning devices, and achieve improved stability and safety, transmission The structure is stable and the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

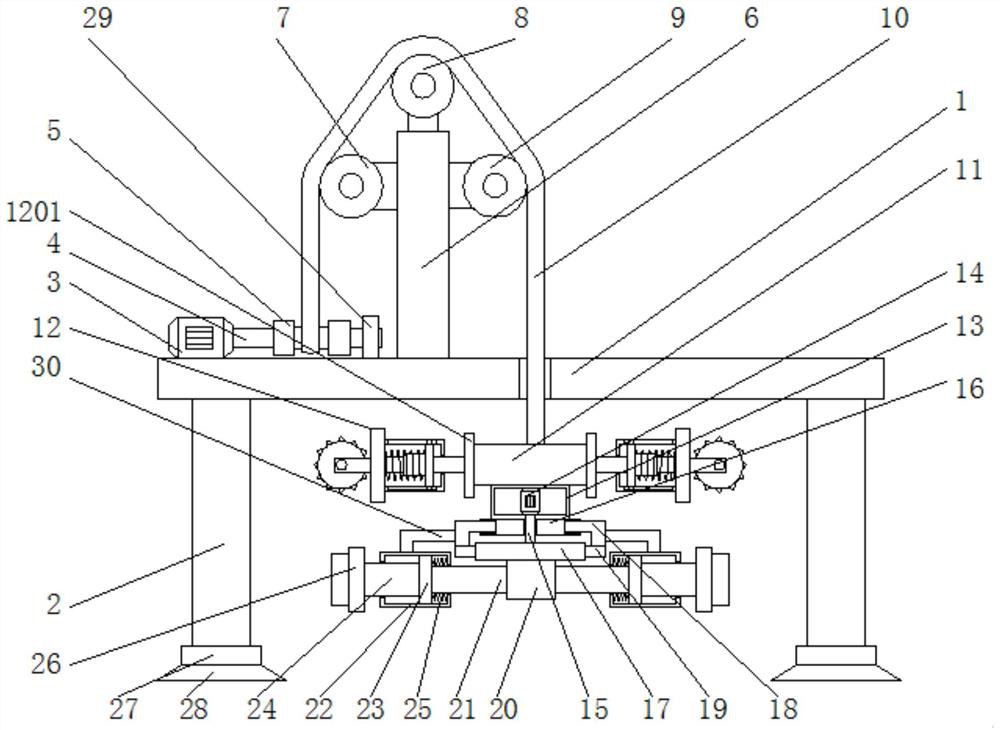

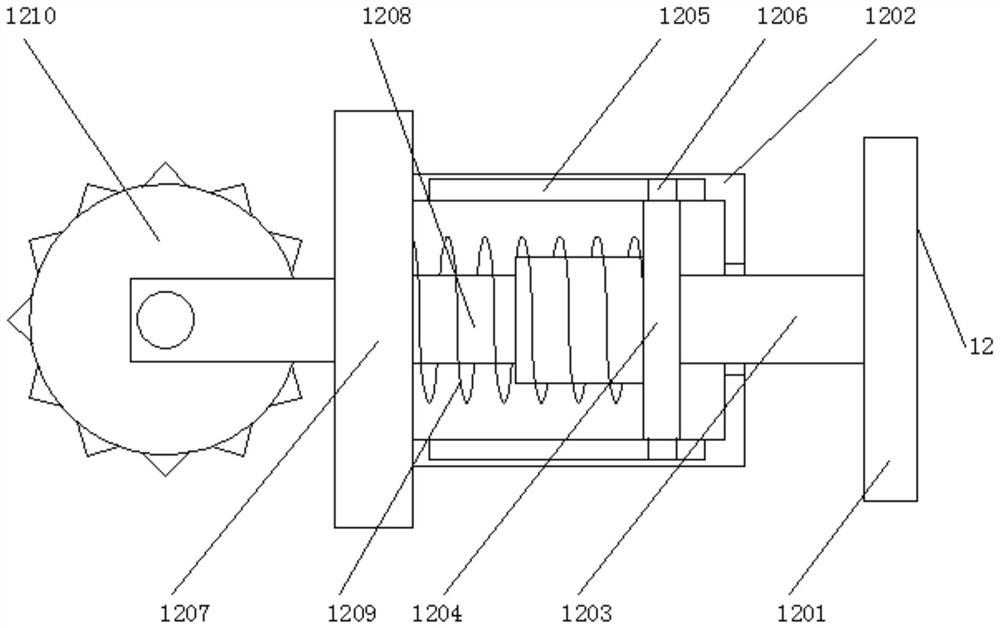

[0017] First implementation: see figure 1 , a geothermal well wall cleaning device, comprising a fixed plate 1, the left and right sides of the bottom of the fixed plate 1 are fixedly connected with a support plate 2, by setting the support plate 2, it plays the role of supporting the fixed plate 1, the support plate 2 The bottom is fixedly connected with a shelving block 27, and the bottom of the shelving block 27 is fixedly connected with a shock-absorbing pad 28. By setting the shelving block 27 and the shock-absorbing pad 28, the shock resistance of the whole device is improved, and the internal components of the cleaning device are avoided from being damaged by vibration. The left side of the top of the fixed plate 1 is fixedly connected with a rotating motor 3, the output shaft of the rotating motor 3 is fixedly connected with a rotating shaft 4, and the surface of the rotating shaft 4 is fixedly connected with a winding wheel 5, and the surface of the rotating shaft 4 is...

no. 2 approach

[0021] The second embodiment: a geothermal well wall cleaning device, including a fixed plate 1, the left and right sides of the bottom of the fixed plate 1 are fixedly connected with a support plate 2, and the left side of the top of the fixed plate 1 is fixedly connected with a rotating Motor 3, the output shaft of the rotating motor 3 is fixedly connected with a rotating shaft 4, the surface of the rotating shaft 4 is fixedly connected with a winding wheel 5, and the top of the fixed plate 1 is fixed on the right side of the rotating shaft 4 Connected with a stabilizing plate 6, the top on the left side of the stabilizing plate 6 is fixedly connected with a first runner 7, the top of the stabilizing plate 6 is fixedly connected with a second runner 8, and the top on the right side of the stabilizing plate 6 is fixed A third runner 9 is connected, the surface of the reel 5 is wound with a first fixed rope 10, and the end of the first fixed rope 10 away from the reel 5 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com