Walking power output mechanism of combine-harvester

A combine harvester and walking power technology, applied in the field of combine harvester and combined harvester walking power output mechanism, can solve the problems of high return on investment, difficult steering, and single-season crops cannot meet the user's income requirements, so as to improve the Longevity and reliability, stable crawler drive structure, and improved cross-area performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

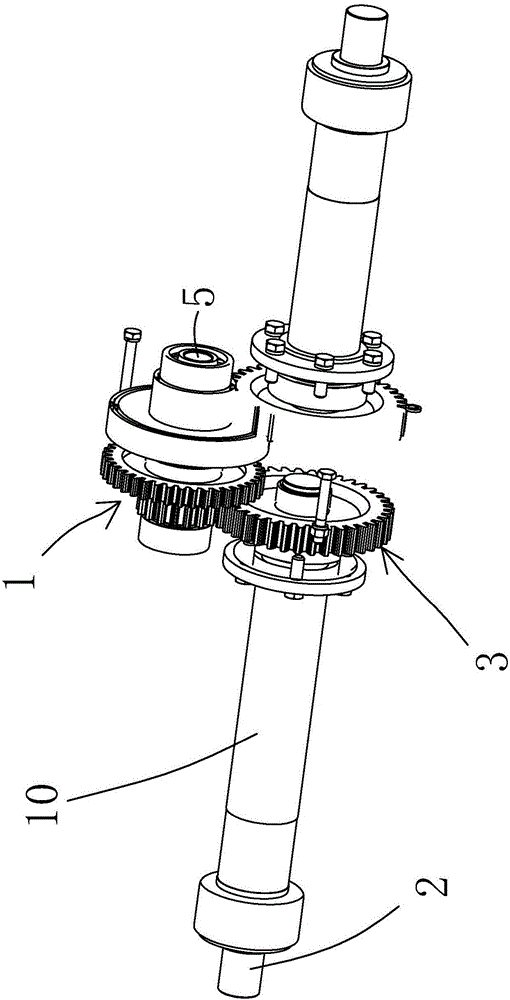

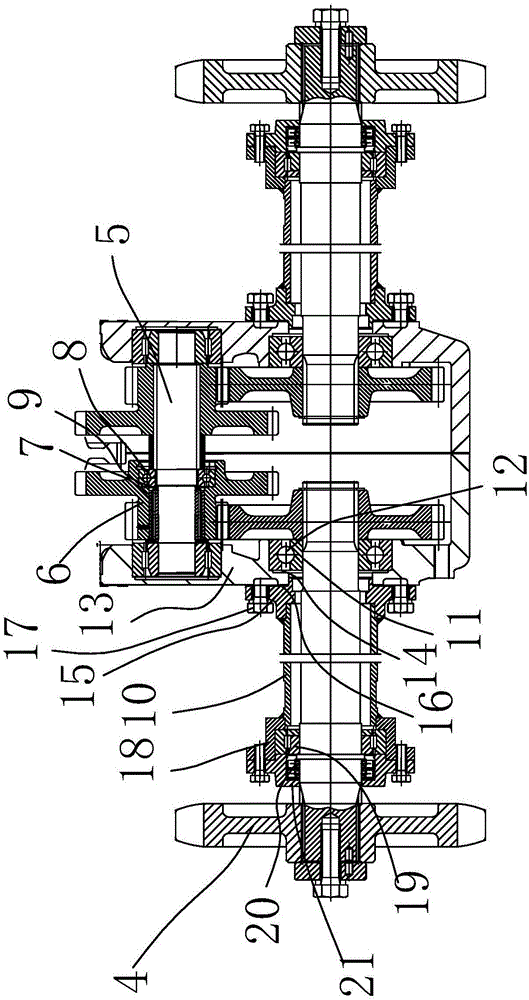

[0029] Such as figure 1 and figure 2 As shown, the walking power output mechanism of the combine harvester includes a power input assembly 1, an output shaft 2, a drive gear assembly 3 and a track wheel assembly 4, where the power input assembly 1 is used to provide the overall power input, and the power input assembly The assembly 1 includes an input shaft 5, an input gear 6, a roller bearing 7, a third rolling bearing 8 and a limiting member 9. The input gear 6 is connected to the input shaft 5, and the rolling bearing 7 and the third rolling bearing 8 are arranged on the input gear 6. Between the input shaft 5 and the limiting member 9 is arranged on the outer end of the input gear 6 and is used to maintain the position of the roller bearing 7 and the third rolling bearing 8, and is used to isolate the two between the roller bearing 7 and the third rolling bearing 8 There is a stopper, and the installation position of the roller bearing 7 and the third rolling bearing 8 c...

Embodiment 2

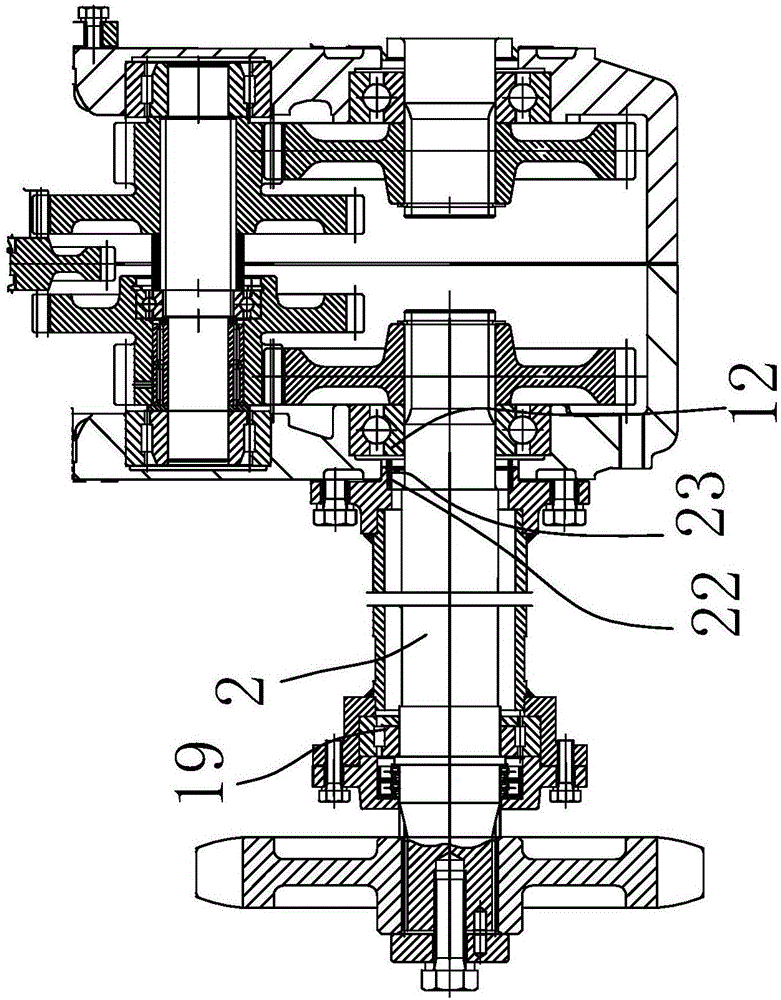

[0033] Most of the structure of this embodiment is the same as Embodiment 1, as image 3 As shown, because it is symmetrical here, half of it is shown. The difference is that the first shaft assembly 11 includes a transverse elastic member 22 and a first rolling bearing 12, and a stepped groove 23 is opened at the inner lower end of the press fit member 15. The elastic member 22 is arranged in the step groove 23, and the two ends of the transverse elastic member 22 respectively act on the first rolling bearing 12 and the stepped groove 23 and are used to adjust the lateral clearance of the first rolling bearing 12. Here, in order to make the first rolling bearing 12 The adjustment is more reasonable. Here, the first rolling bearing 12 is adjusted through the transverse elastic member 22. Here, since one end of the transverse elastic member 22 is pressed against the step groove 23, when the press fit part 15 is installed, the press fit part 15 Adaptively adjust the position of ...

Embodiment 3

[0035] Most of the structure of this embodiment is the same as Embodiment 2, as Figure 4 As shown, because it is symmetrical here, half of it is shown. The difference is that the second shaft assembly 29 also includes a longitudinal elastic member 24, and there is a longitudinal groove for the longitudinal elastic member 24 to be placed next to the second rolling bearing 19 and the dome body 18. 25. The longitudinal elastic member 24 leans against the lower cover surface of the dome body 18 acting on the second rolling bearing 19. In order to make the gap adjustment in the longitudinal direction more reasonable, here the longitudinal elastic member 24 abuts against the dome body 18 When installing the lower cover of the round cover body 18, the longitudinal gap between the sleeve member 10 and the output shaft 2 can be adjusted by the longitudinal elastic member 24, thereby realizing the adjustment of the longitudinal gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com