Mechanical intelligent self-adaption two-gear automatic-gear-shifting hub

An automatic variable speed and self-adaptive technology, applied in the direction of wheel hubs, mechanical equipment, power devices, etc., can solve the problems of reducing volume and achieve the effects of improving power performance, controlling vehicle emissions, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

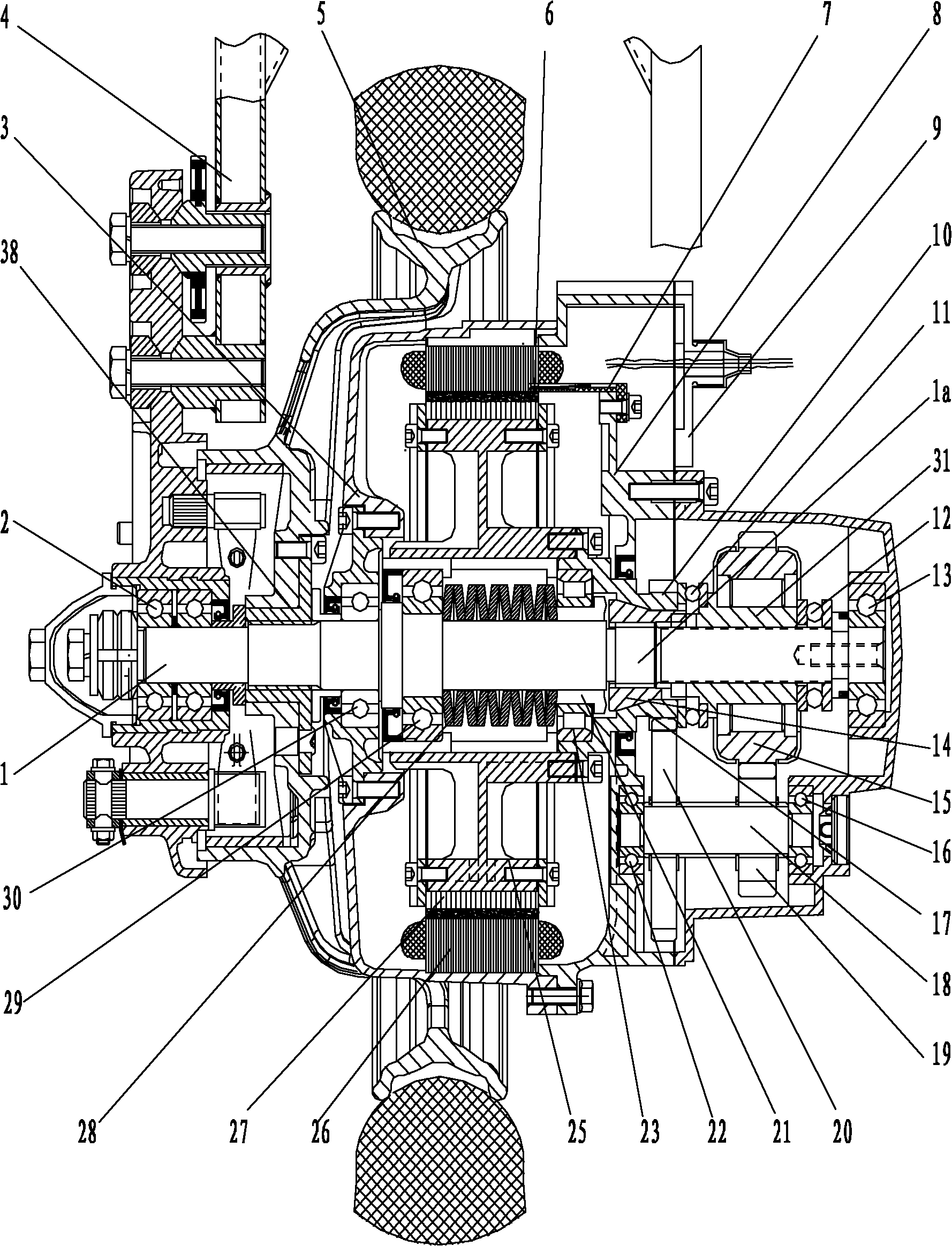

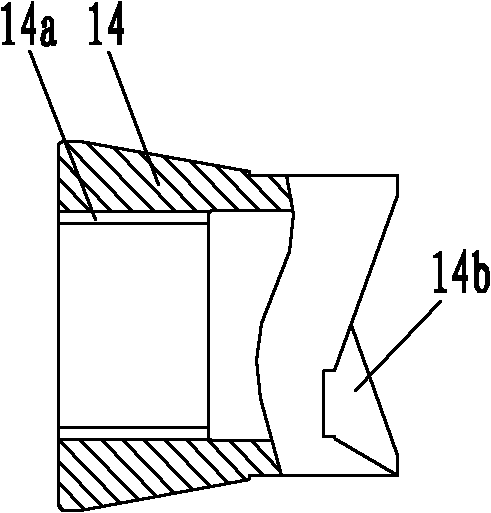

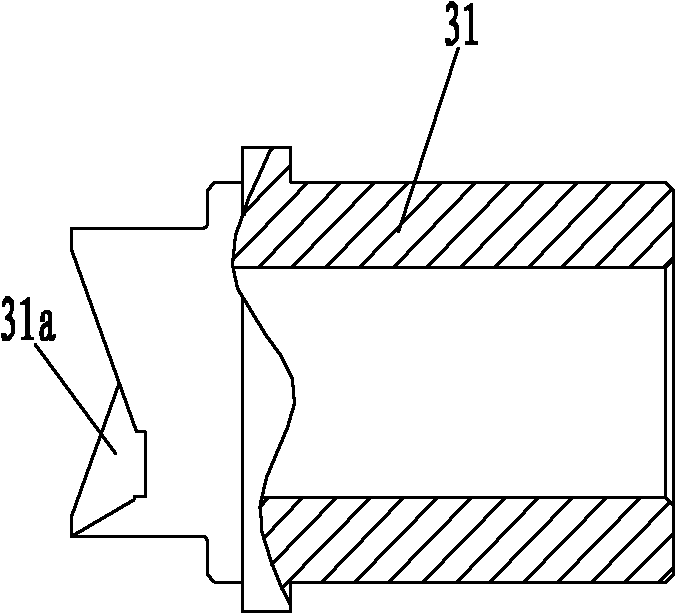

[0031] figure 1 Is a schematic view of the axial cross-sectional structure of the present invention figure 2 Is the structure diagram of the outer cone sleeve in the axial direction of the torus, image 3 Schematic diagram of the inner ring structure of the overrunning clutch Figure 4 Schematic diagram of the overrunning clutch structure; Figure 5 It is a schematic diagram of supporting column, supporting plate and reed coordination, Image 6 Is a schematic diagram of the reed structure, Figure 7 It is a partial sectional structural schematic diagram of the overrunning clutch in the axial direction, as shown in the figure: the power device of this embodiment is a motor, which rotates counterclockwise from left to right when working, and the motor is an inner rotor motor.

[0032] The mechanical intelligent adaptive two-speed automatic transmission hub of the present invention includes a power device, a box body 3, a transmission shaft 1 and wheels 5. The transmission shaft 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com