Plant lamp

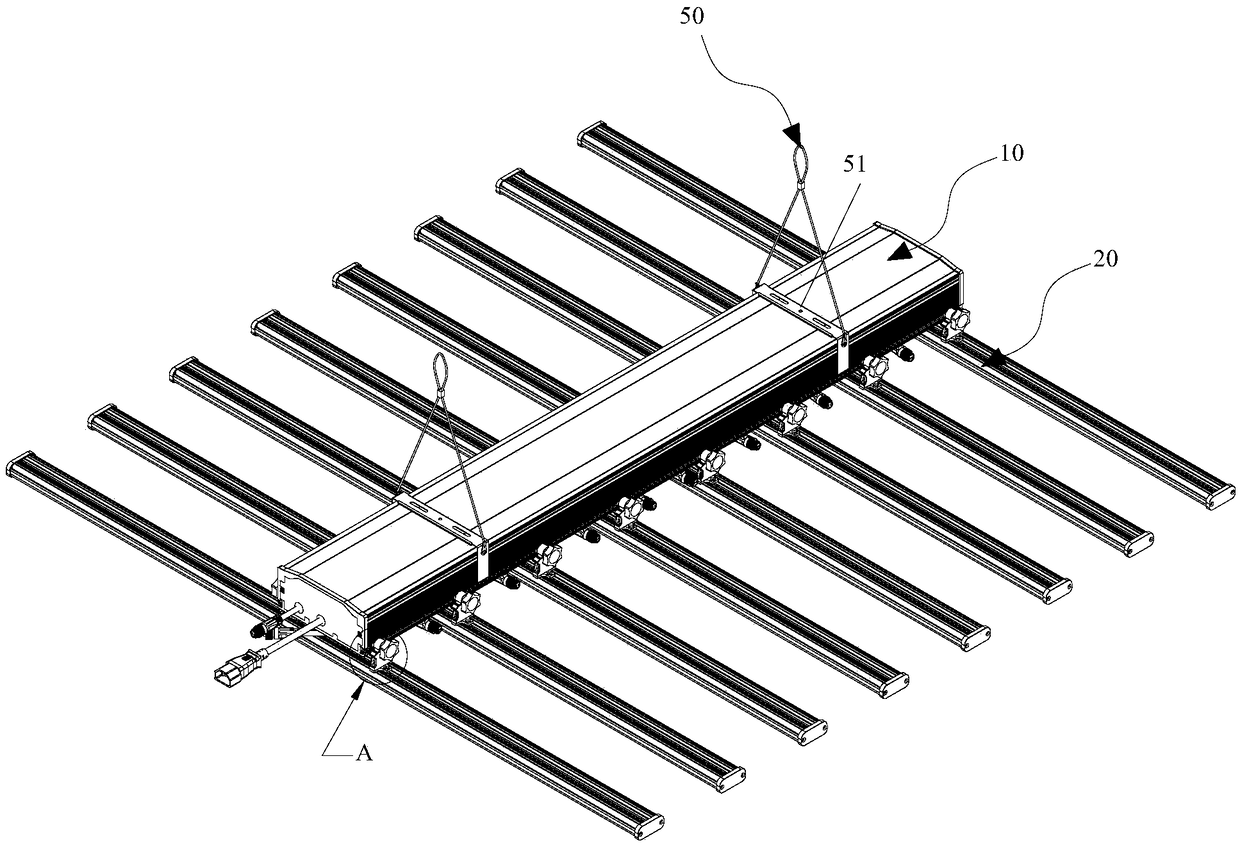

A technology for lamps and plants, applied in the field of lighting, can solve the problems of cumbersome and complicated installation and disassembly operations, and achieve the effects of reducing the high cost of packaging and transportation, improving the efficiency of disassembly and assembly, and improving the lighting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

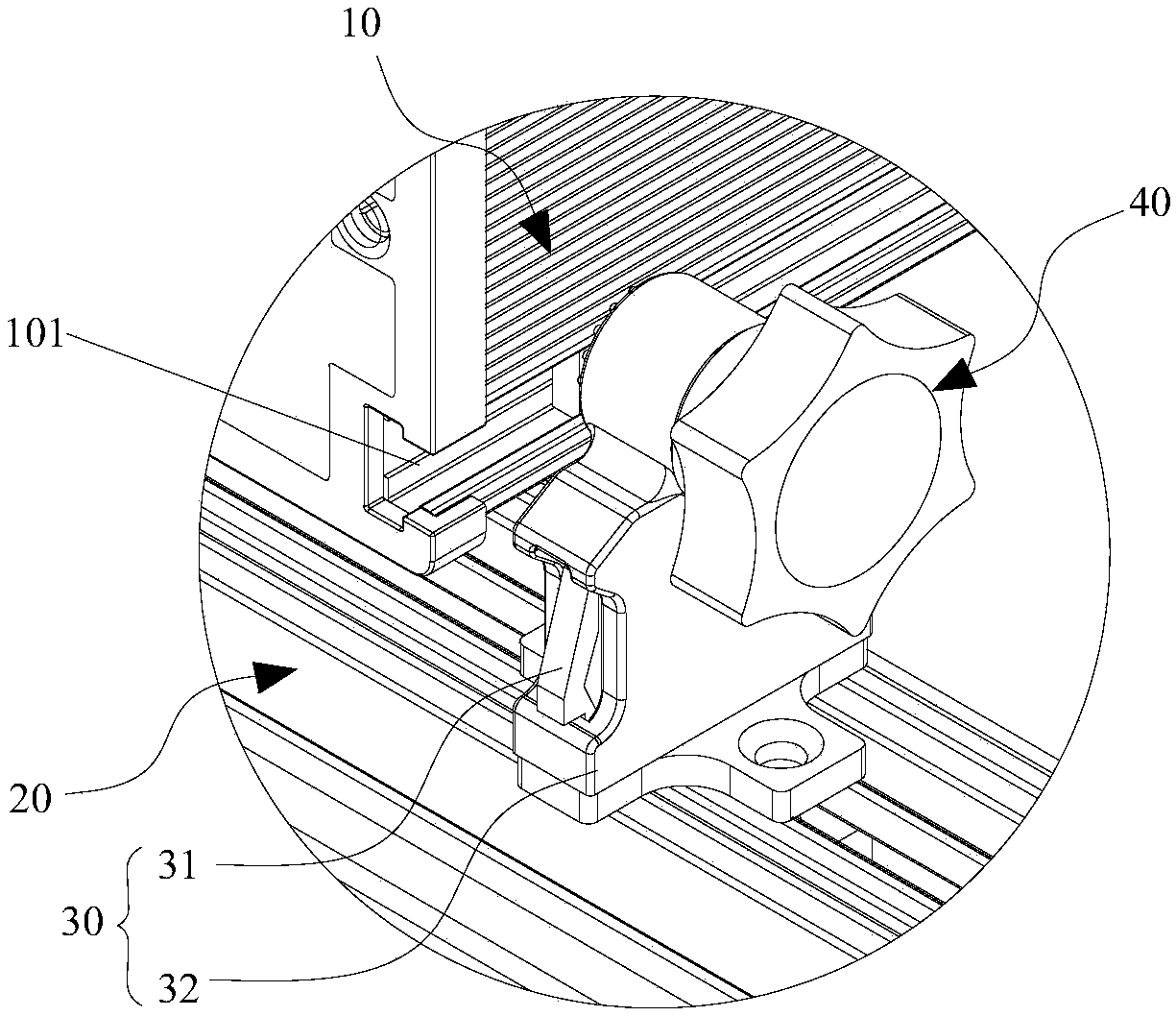

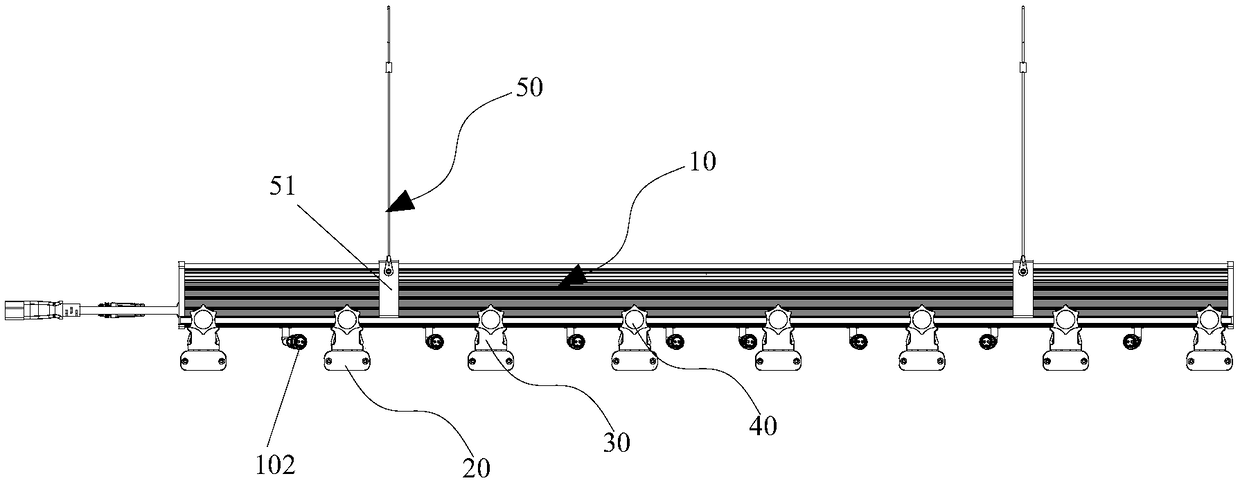

[0049] Furthermore, please also refer to figure 2 , Figure 7 As a specific embodiment of the plant lamp provided by the present invention, the nut includes a mounting plate 411 installed in the chute 101, and a fixing post 412 arranged on the mounting plate 411, and the fixing post 412 extends out of the chute 101 In addition, the fixing column 412 is provided with internal threads. The thumb screw includes a head 421 and a connecting portion 422 connected to the head 421. The connecting portion 422 is provided with an external thread for threaded connection with the internal thread. Through the cooperation of the internal thread and the external thread, hand-tightening The connection of the screw and the nut is fixed. When it needs to be disassembled, it is only necessary to reversely rotate the thumb screw to loosen the thumb screw and the nut, and the adjustment is very simple and convenient.

[0050] Furthermore, please also refer to figure 2 , Figure 7 , as a spe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap