Divergent die and pouring shunting device for pig machine

A shunt device and cast iron machine technology, which is applied in the directions of casting mold composition, casting mold, casting equipment, etc., can solve the problems of low casting rate, low casting rate, fish mouth shunt is not easy to achieve an ideal state, etc., and improve casting rate. , the effect of shortening the repair time

Active Publication Date: 2019-03-15

PANGANG GROUP TITANIUM INDAL

View PDF11 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are two commonly used shunt methods in the prior art, one is to use fish mouth shunt, the fish mouth shunt is not easy to achieve the ideal state, the molten iron flow on both sides of the taphole cannot be automatically adjusted, and the mold rate is low; the other is to use three The diversion through

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

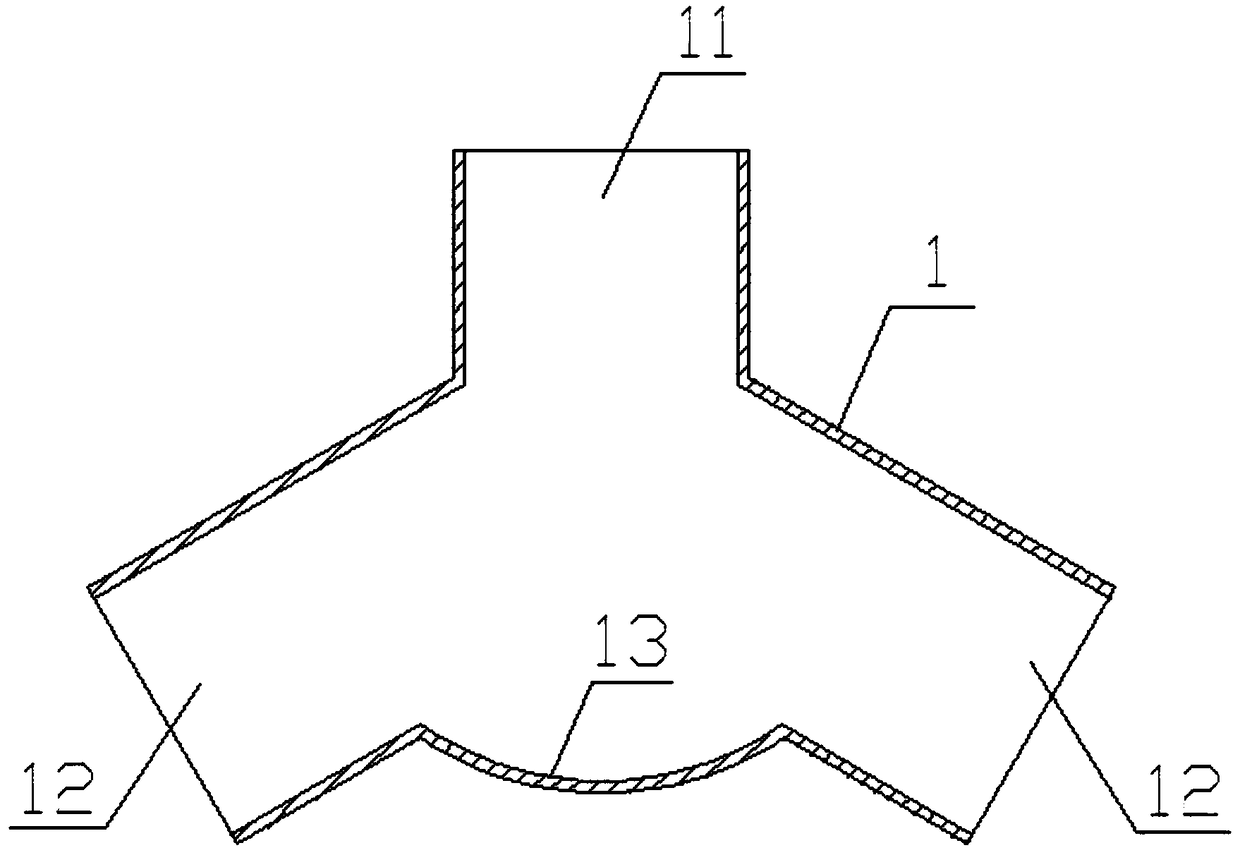

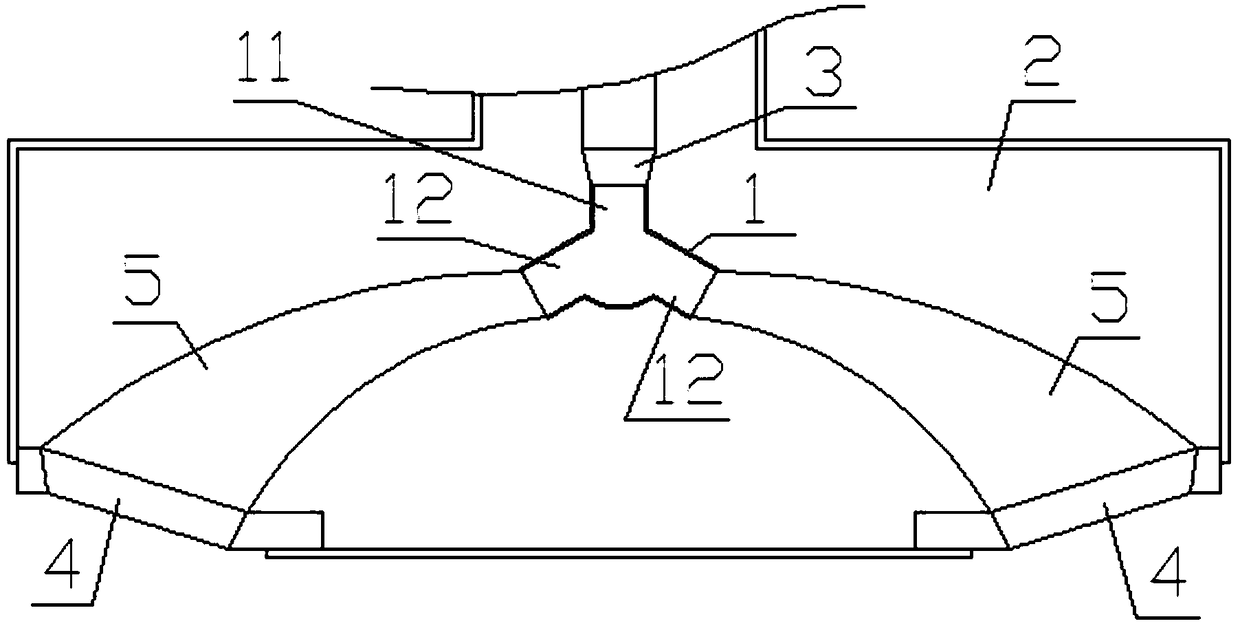

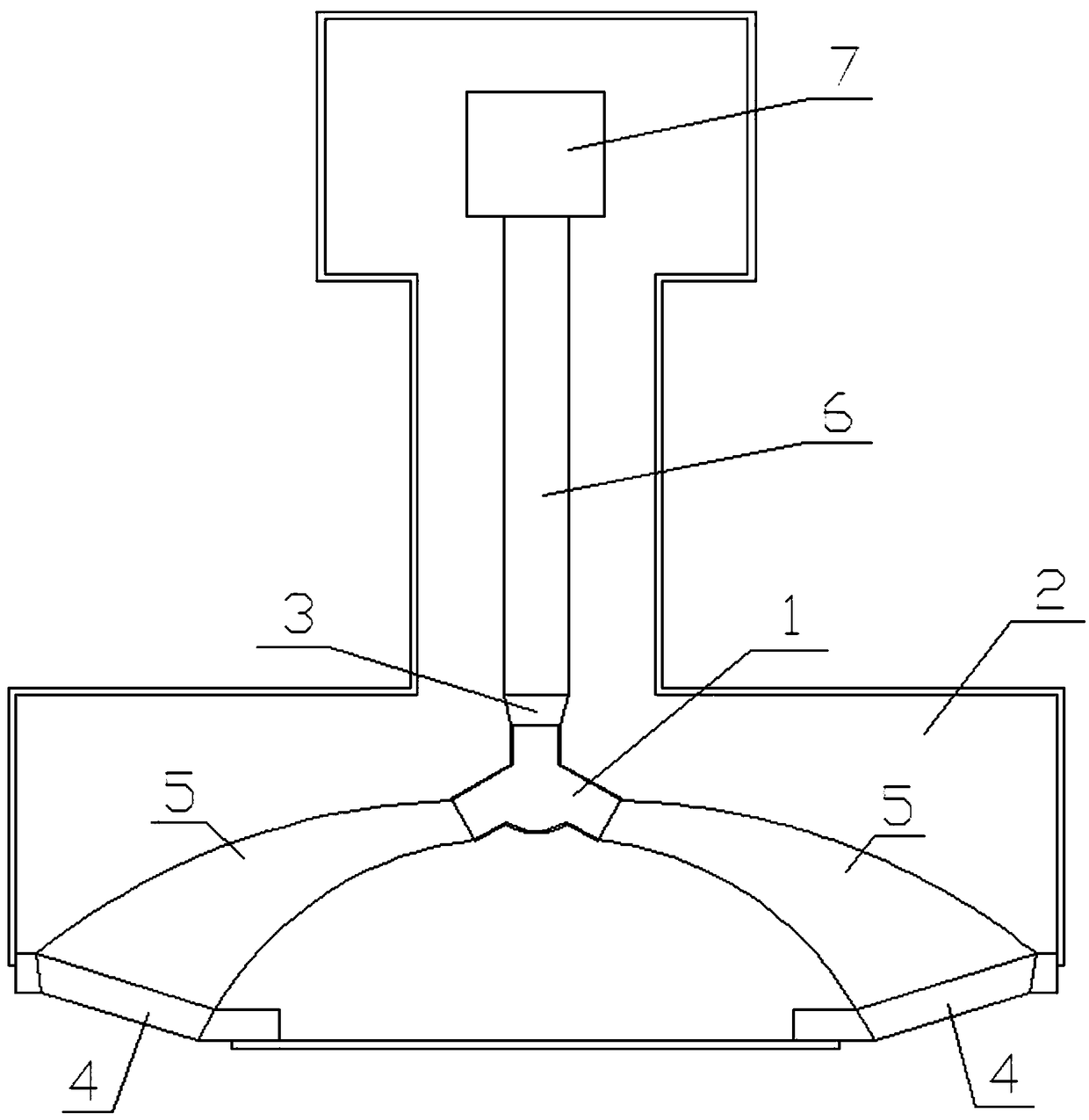

The invention relates to a divergent die and a pouring shunting device for a pig machine, and belongs to the technical field of cast iron equipment. The divergent die for the pig machine comprises aninlet flow passage. The tail end of the inlet flow passage is connected with two outlet flow passages, and the inlet flow passage and the two outlet flow passages are of an inverted Y-shaped structure. A joint of the two outlet flow passages is arranged as an arc-shaped concave surface. The two ends of the arc-shaped concave surface is joined with the inner walls of the outlet flow passages. The divergent die for the pig machine is of a symmetrical structure with a center line of the inlet flow passage as an axis of symmetry. The arc-shaped concave surface in the divergent die for the pig machine can play a buffering and regulating role during flow passing, and can resist the scouring of high-temperature iron water for a long time, so that the shunting reaches an ideal state, and the flowrate of the iron water of iron discharging ports at both sides is adjusted automatically, and thus the casting mould rate is improved.

Description

technical field [0001] The invention relates to a splitter mold for a cast iron machine and a pouring splitter device for a cast iron machine, belonging to the technical field of cast iron equipment. Background technique [0002] Iron casting machine is the equipment that continuously casts molten iron into iron blocks. The invention relates to the iron casting machine process as follows: semi-steel molten iron smelted in a large-scale titanium slag electric furnace, after desulfurization, carbonization, and temperature adjustment, the crane lifts the ladle containing the molten iron from the refining furnace to the pouring flat car, and transfers it to the pouring steel position, the hydraulic mechanism pulls the lower plate of the ladle, the molten iron flows out through the ladle outlet, and then flows into the cast iron mold of the cast iron machine through the molten iron distribution tank, and the cast iron mold filled with molten iron moves slowly upwards driven by th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B22C9/08B22D35/04

CPCB22C9/082B22D35/04

Inventor 吴相权陈小勇张峰胡松白南军李腾川刘敏马勇王丽萍

Owner PANGANG GROUP TITANIUM INDAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap