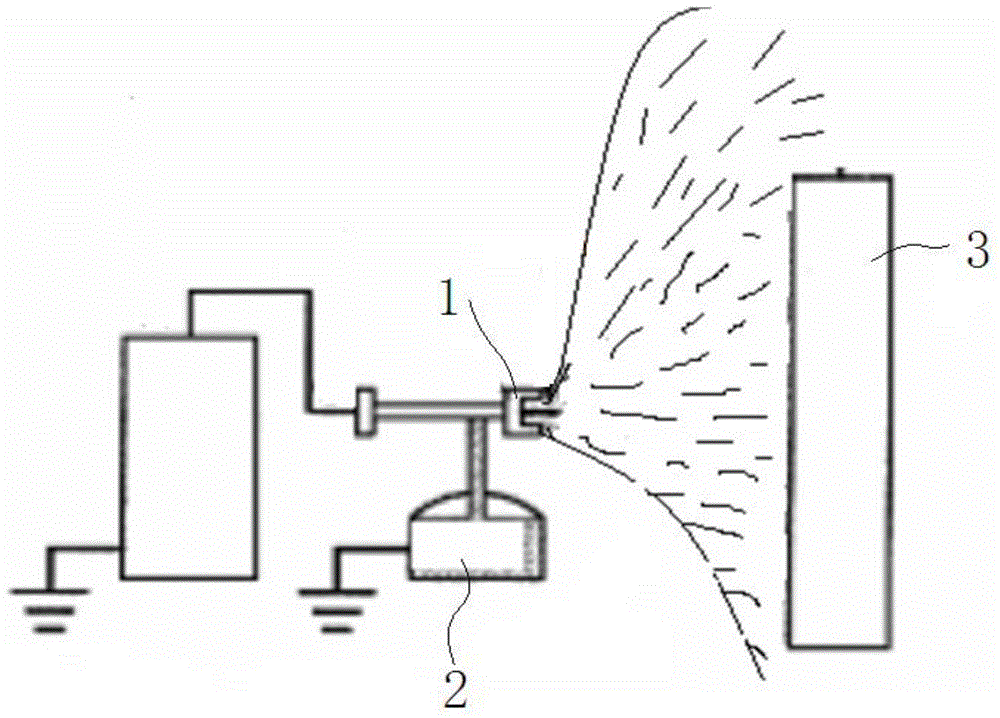

Method and device for electrostatic spraying of release agent

An electrostatic spraying and release agent technology, which is applied to the device for coating liquid on the surface, liquid spraying equipment, coating and other directions, can solve the problems of excessive alkane emission, poor transfer rate, large workshop odor, etc., to reduce the dosage, The effect of increasing the transfer rate and reducing the intensity of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the car seat polyurethane foam mold as an example to illustrate, the mold size is: length 380mm, width 380mm, height 100mm.

[0029] A method for electrostatic spraying of a release agent, comprising the steps of:

[0030] (1) Steps for configuring the release agent:

[0031] Configure a release agent, the release agent is prepared from the following raw materials by weight percentage: 95% petroleum ether, 5% paraffin, the resistivity of the release agent is 800 megohm cm, the viscosity is 150 centipoise, and the flash point is ≥ 55°C ;

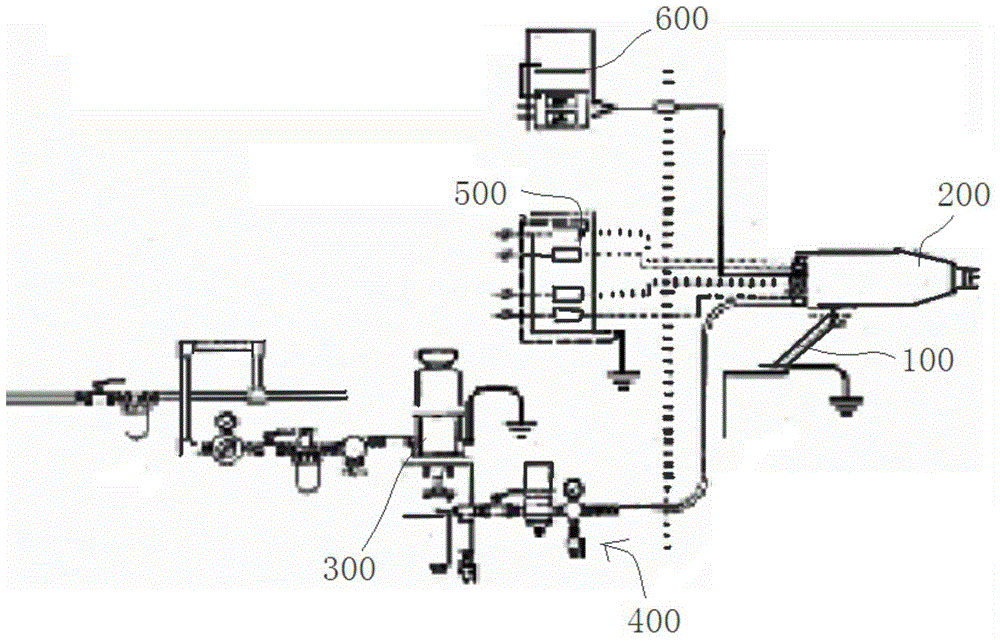

[0032] (2) Preparation steps:

[0033] The release agent prepared by step (1) is stored in the release agent storage tank, and at the same time, the spray gun is distributed and the mold to be sprayed with release agent is grounded;

[0034] (3) Spraying steps

[0035] First, the mold to be sprayed with release agent is transported to the spraying position, and at the same time, an air pump is used to pressurize the release ag...

Embodiment 2

[0037] Take the car seat polyurethane foam mold as an example to illustrate, the mold size is: length 380mm, width 380mm, height 100mm.

[0038] A method for electrostatic spraying of a release agent, comprising the steps of:

[0039] (1) Steps for configuring the release agent:

[0040] Configure a release agent, the release agent is prepared from the following raw materials by weight percentage: 96% petroleum ether, 4% paraffin, the resistivity of the release agent is 800 megohm cm, the viscosity is 150 centipoise, and the flash point is ≥ 55°C ;

[0041] (2) Preparation steps:

[0042] The release agent prepared by step (1) is stored in the release agent storage tank, and at the same time, the spray gun is distributed and the mold to be sprayed with release agent is grounded;

[0043] (3) Spraying steps

[0044] First, the mold to be sprayed with release agent is transported to the spraying position, and at the same time, an air pump is used to pressurize the release ag...

Embodiment 3

[0046] Take the car seat polyurethane foam mold as an example to illustrate, the mold size is: length 380mm, width 380mm, height 100mm.

[0047] A method for electrostatic spraying of a release agent, comprising the steps of:

[0048] (1) Steps for configuring the release agent:

[0049] Configure a release agent, the release agent is prepared from the following raw materials by weight percentage: 97% petroleum ether, 3% paraffin, the resistivity of the release agent is 800 megohm cm, the viscosity is 150 centipoise, and the flash point is ≥ 55°C ;

[0050] (2) Preparation steps:

[0051] The release agent prepared by step (1) is stored in the release agent storage tank, and at the same time, the spray gun is distributed and the mold to be sprayed with the release agent is grounded;

[0052] (3) Spraying steps

[0053] First, the mold to be sprayed with release agent is transported to the spraying position, and at the same time, an air pump is used to pressurize the release ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap