Flux and method for refining molten steel using the same

A technology of flux and molten iron, which is applied in the steel manufacturing process, the improvement of process efficiency, and the manufacture of converters, etc., can solve the problems such as the decrease of sedation effect, and achieve the effect of suppressing or preventing splashing and improving the slag sedation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

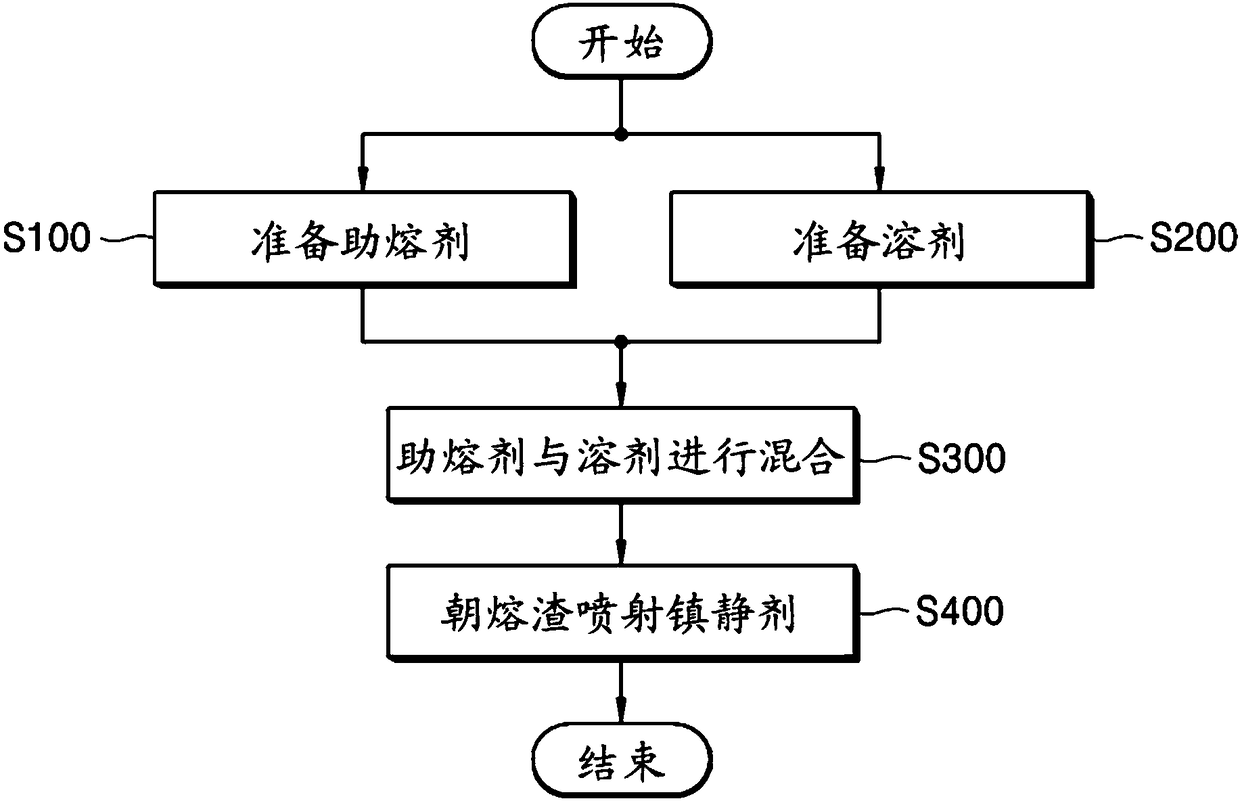

[0037] Below, the embodiment of the present invention will be described in more detail with reference to the accompanying drawings, but the present invention is not limited to the following embodiments and can be implemented in various ways, and the following embodiments are provided herein in order to disclose the present invention completely, so that the ordinary A skilled artisan fully appreciates the scope of the present invention. The same symbols in the drawings represent the same elements.

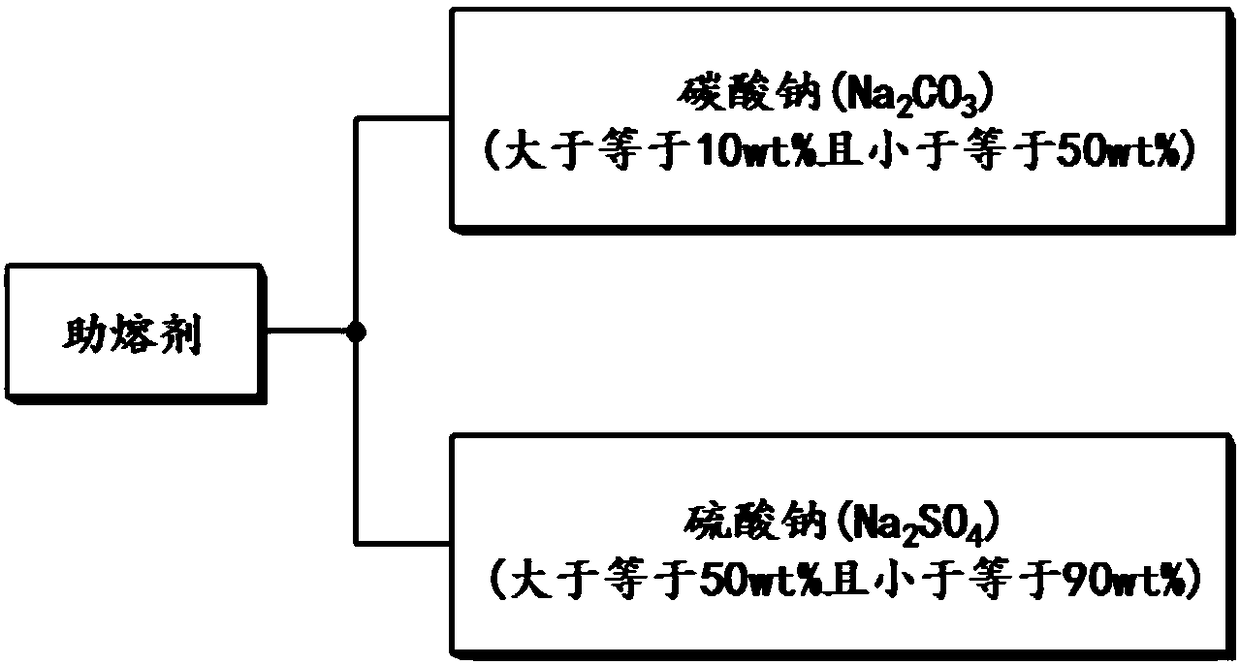

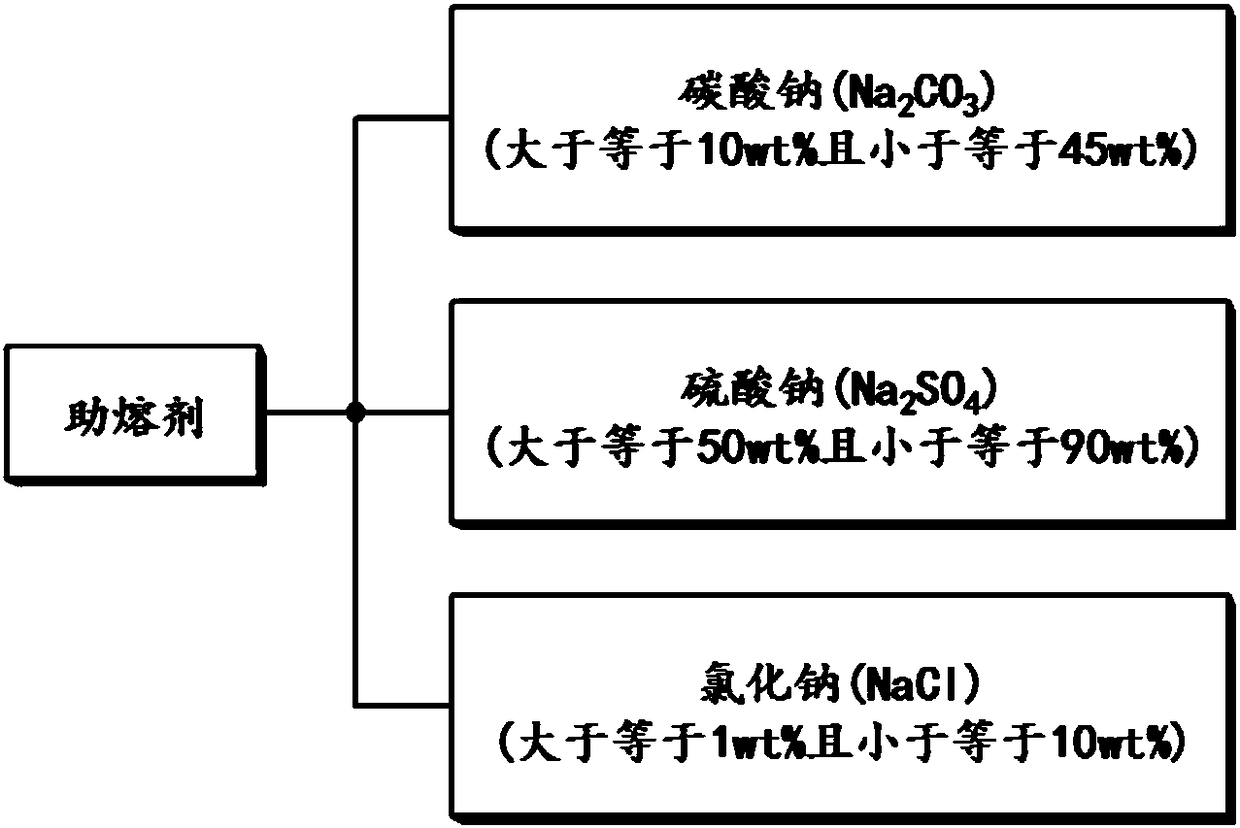

[0038] The invention relates to a flux which can effectively suppress foaming of molten slag and a method for refining molten iron using the flux. More particularly, the present invention relates to a flux capable of suppressing or preventing splashing of molten slag overflow and its addition method. In addition, the flux according to the embodiment may be a flux added to the slag in the slag pot when the slag in the converter is discharged into the slag pot.

[0039] Refer below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com