Cast-on method for continuously casting half-rimmed steel

A semi-boiling, continuous casting technology, applied in the field of molten steel continuous casting, can solve the problems of continuous casting nozzle clogging, affecting the quality of casting slab, poor fluidity of molten steel, etc., and achieve the effects of convenient operation, prevention of molten steel splashing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

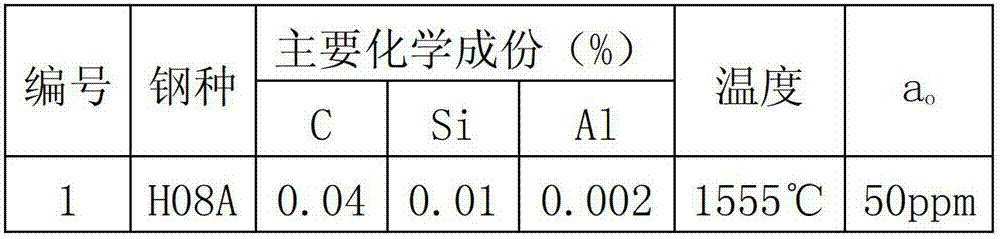

[0049] (1) Molten steel condition

[0050]

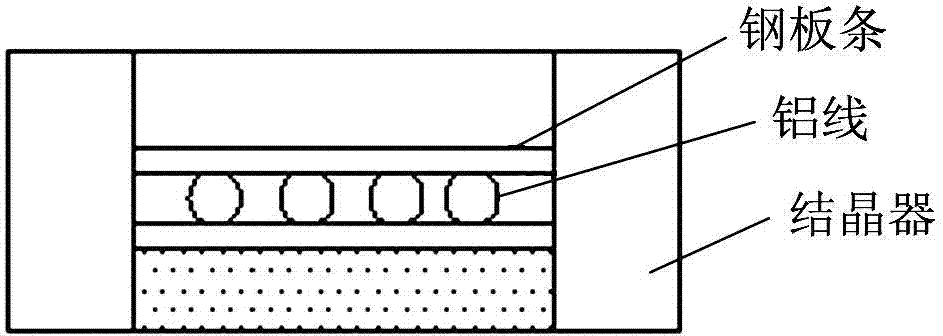

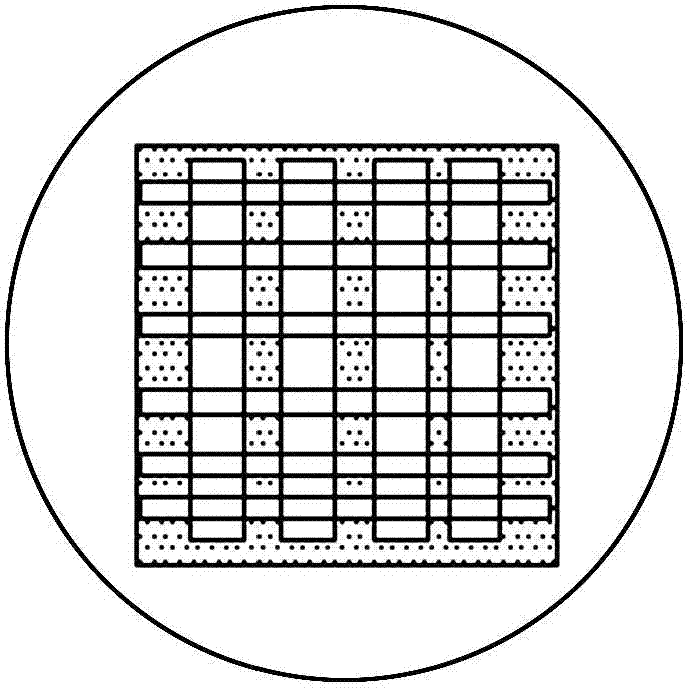

[0051] (2) Place coagulation-promoting steel strips with a thickness of about 160mm in the 150×150mm billet mold first, then place two ∮13mm and 90mm aluminum strips in parallel in the middle area of the steel strips, and place multiple aluminum strips around the aluminum strips Surrounded by steel strips, finally press the aluminum strips with 4 steel strips in a well shape to fix them.

[0052] (3) Within 12 seconds of continuous casting, start casting according to 1 / 3~1 / 2 steel flow, and after forming a liquid steel surface with a height of about 100mm in the crystallizer, it enters the normal pouring stage.

[0053] (4) During the pouring process, the molten steel level rises steadily, and there is no boiling or splashing of molten steel. Slab surface inspection and low-magnification inspection are all qualified.

example 2

[0055] (1) Molten steel condition

[0056]

[0057] (2) First place a coagulation-promoting steel strip with a thickness of about 180mm in the 150×150mm billet crystallizer, then place four ∮13mm and 54mm aluminum strips in parallel in the middle area of the steel strips, and place multiple aluminum strips around the aluminum strips Surrounded by steel strips, and finally press the aluminum strips with two steel strips in the shape of a well to fix them.

[0058] (3) Within 15 seconds of continuous casting, start pouring according to 1 / 3 to 1 / 2 steel flow. After forming a liquid steel surface with a height of about 110mm in the crystallizer, it enters the normal pouring stage.

[0059] (4) During the pouring process, the molten steel level rises steadily, and there is no boiling or splashing of molten steel. Slab surface inspection and low-magnification inspection are all qualified.

example 3

[0061] (1) Molten steel condition

[0062]

[0063] (2) Place coagulation-promoting steel strips with a thickness of about 170mm in the 150×150mm billet mold first, then place two aluminum strips of ∮13mm and 95mm in parallel in the middle area of the steel strips, and place multiple aluminum strips around the aluminum strips Surrounded by steel slats, finally use 5 steel slats to press the aluminum strips in a well shape and fix them.

[0064] (3) Within 15 seconds of continuous casting, start pouring according to 1 / 3 to 1 / 2 steel flow. After forming a liquid steel surface with a height of about 110mm in the crystallizer, it enters the normal pouring stage.

[0065] (4) During the pouring process, the molten steel level rises steadily, and there is no boiling or splashing of molten steel. Slab surface inspection and low-magnification inspection are all qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com