Slag foaming killing material, and slag foaming killing method

A slag foaming and sedation technology, applied in steel manufacturing process, manufacturing converters, climate sustainability, etc., can solve problems such as increased refining costs, worsened operating environment, increased blowing volume, etc., to maintain productivity, High sedative effect, anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

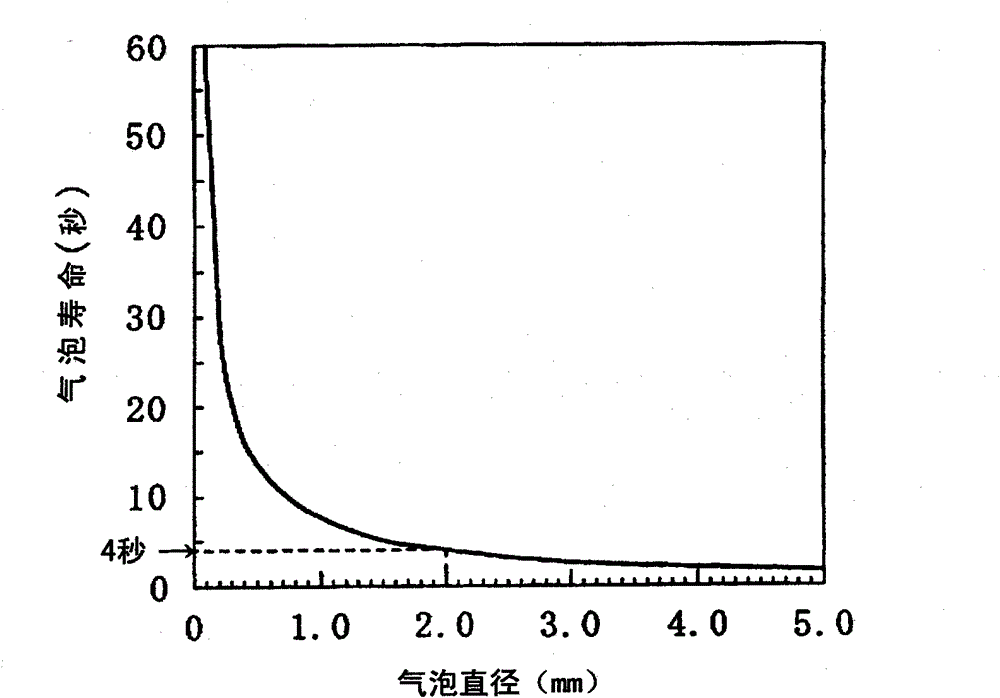

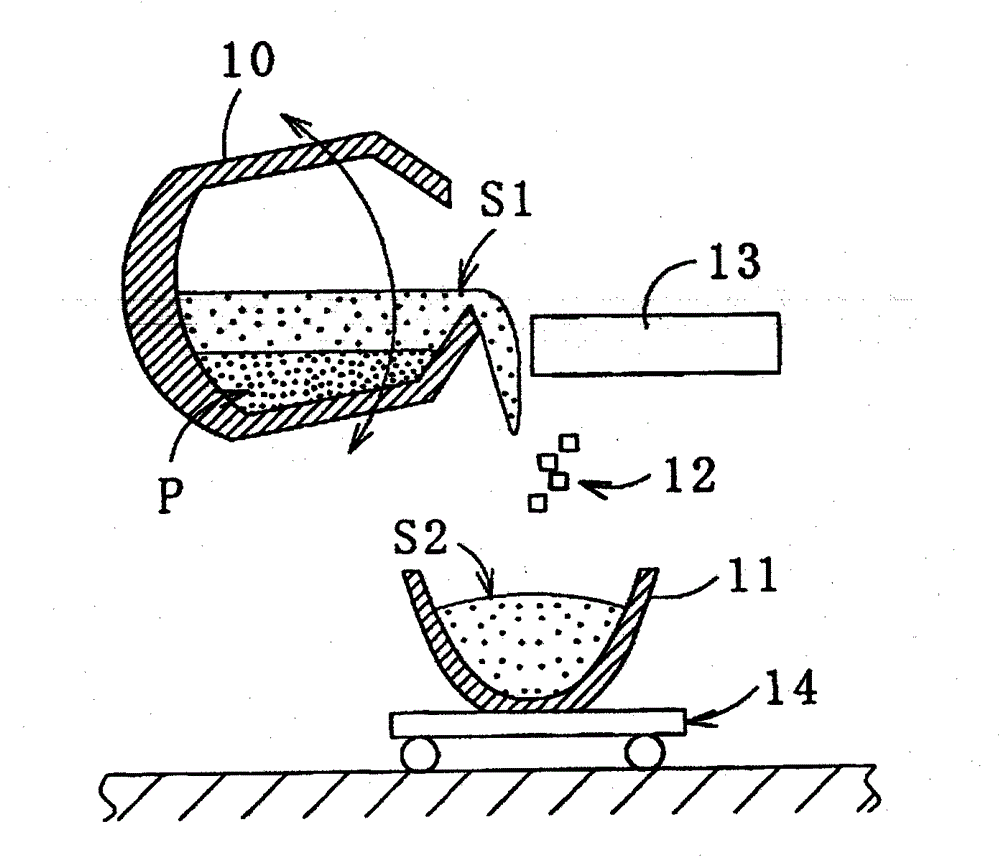

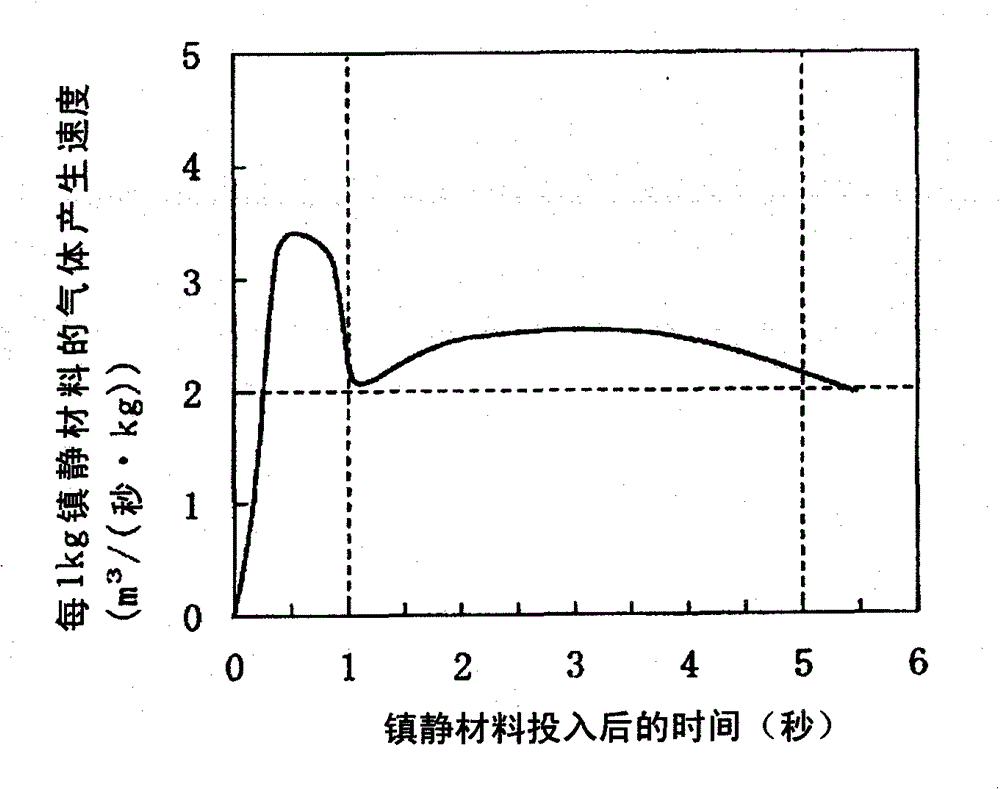

[0061] figure 1 It is a graph showing the relationship between the diameter of bubbles in the molten slag and the lifetime of the bubbles, the horizontal axis represents the diameter of the bubbles, and the vertical axis represents the lifetime of the bubbles. also, figure 2 It is an explanatory drawing of the slag foaming calming method of this embodiment.

[0062] The slag foaming calming material (hereinafter also simply referred to as calming material) of this embodiment is a calming material containing a mixture of carbon powder and water in a container made of a water-impermeable combustible substance. This will be described in detail below.

[0063] The carbon powder has the effect of not sticking to the molten slag on its surface due to its poor wettability with the molten slag. Therefore, if the carbon powder enters the slag liquid film between the air bubbles and the air bubbles, the slag liquid film is removed, so that the bubbles merge . Here, refer to figure...

Embodiment 1

[0109] Examples 1 to 12 all use a mixture of 30% to 60% by mass of water and 20% to 40% by mass of carbon powder with a particle size of 0.2 to 2 mm in a container made of a water-impermeable combustible substance. Calming materials (Materials A~L). As a result, by throwing in 120 kg of this calming material, the foaming could be calmed, and molten slag of 10 tons (target value) or more could be discharged. Especially in Example 1, when discharging molten slag with a basicity of 1.1, 40 kg of calming material (material A) was placed in the slag removal pot before the start of slag removal, and then melted 30 seconds after the start of slag removal. 80kg of sedation material (material A) was added to the slag removal position. As a result, the sedation effect was improved, and 14 tons of molten slag could be discharged. In addition, the same result was obtained also about Example 2 which injected 40 kg of damping material (material B) within 30 seconds from the start of deslag...

Embodiment 5

[0112] Example 5 uses a calming material (material E) with a mass of the mixture packed in a vinyl bag of 0.8 kg (less than 1 kg). Therefore, compared with Example 2, penetration into the molten slag is insufficient, and the discharge of the molten slag is insufficient. The volume is 11 tons.

[0113] On the other hand, Example 6 used a calming material (material F) in which the mass of the mixture packed in a plastic bottle was 12 kg (more than 10 kg). Therefore, penetration into the molten slag was sufficient, and 14 tons of molten slag could be discharged in the same manner as in Example 2. However, the mass of the calming material is too heavy, so the workability of manufacturing and transportation is inferior to that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com