Allogenic different-diameter reverse-screwing bolt fastening assembly capable of never being loose

A technology for fastening components and bolts, applied to threaded fasteners, locking fasteners, bolts, etc., can solve problems such as increased loosening resistance, difficult maintenance and disassembly, and damaged bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

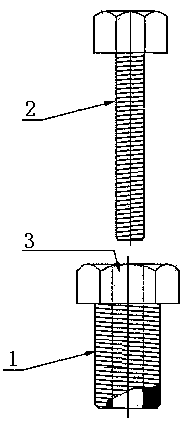

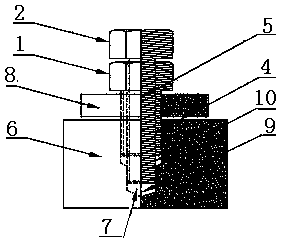

[0054] Such as figure 1 , figure 2 As shown, a different-body and different-diameter anti-rotation bolt fastening assembly is made, and the assembly includes bolts, and the bolts include bolt heads and screw rods; there are two bolts, one of which is the first bolt 1, and the other is the first bolt 1. Two bolts 2; the first bolt 1 is provided with a through hole 3 that runs through the entire longitudinal axis, the length of the screw rod of the second bolt 2 is greater than the full length of the first bolt 1, and the screw rod of the second bolt 2 can be obtained from Pass through the through hole 3; the screw rod of the first bolt 1 and the screw rod of the second bolt 2 are respectively provided with external threads, and the two external threads rotate in opposite directions; in this embodiment, the screw rod of the first bolt 1 Set as left-handed big screw rod 4, the screw rod of second bolt 2 is set as right-handed small screw rod 5. In this way, the anti-rotation b...

Embodiment 2

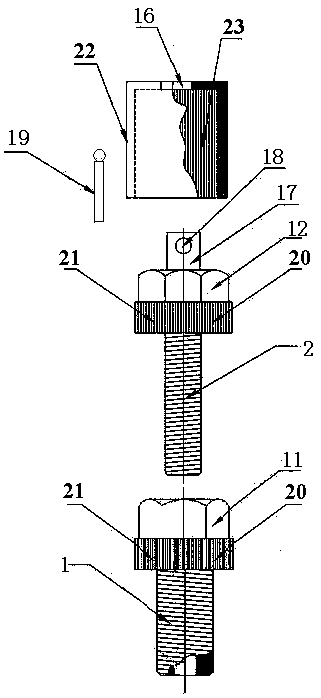

[0060] Such as image 3 As shown, on the basis of Embodiment 1, the outer surface of the first bolt head 11 is divided into two parts: the outer polygonal column 13 and the outer toothed cylinder 20, and the outer surface of the second bolt head 12 is also divided into the outer surface The polygonal column 13 and the outer toothed cylinder 20 are two parts; the outer surface of the outer toothed cylinder on the first bolt head 11 and the outer surface of the outer toothed cylinder on the second bolt head 12 are provided with the same shape and specification. Straight tooth pattern 21; there is also a cylindrical locking card 22, the inner wall of the cylindrical locking card 22 is provided with an inner vertical tooth pattern 23 matching the outer vertical tooth pattern 21; forming a tooth lock type different diameter Back-tighten the bolts to secure the assembly.

[0061] Further, the bottom end surface of the cylindrical locking clip 22 can be set as a closed end surface. ...

Embodiment 3

[0066] Such as Figure 4 , 5 , 6, on the basis of embodiment 1, also make pointed set screw 24 in addition, described set screw 24 comprises nut and stud, and described stud is provided with external screw thread; The outer end surface of the bolt head 11 is provided with an annular positioning groove 25 around the longitudinal axis of the bolt. In this embodiment, the annular positioning groove 25 is arranged so that the cross section of the groove is V-shaped; on the second bolt head 12 There are penetrating screw holes 26 arranged in a circular shape around the longitudinal axis of the bolt. In this embodiment, there are two screw holes 26, and the inner wall of the screw hole 26 is provided with a screw hole that matches the external thread on the nail post. The internal thread, and equipped with two screw-shaped locking clips; in this way, it is made into a nail-locking type different body and different diameter anti-rotation bolt fastening assembly.

[0067] In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com