Potato rubbing and soil-removing device

A potato and center position technology, applied in the fields of application, food processing, food science, etc., can solve the problems of high cost of cleaning potatoes, large water consumption, and long time consumption, so as to reduce the cleaning cost of desliming and improve the effect of desliming , the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

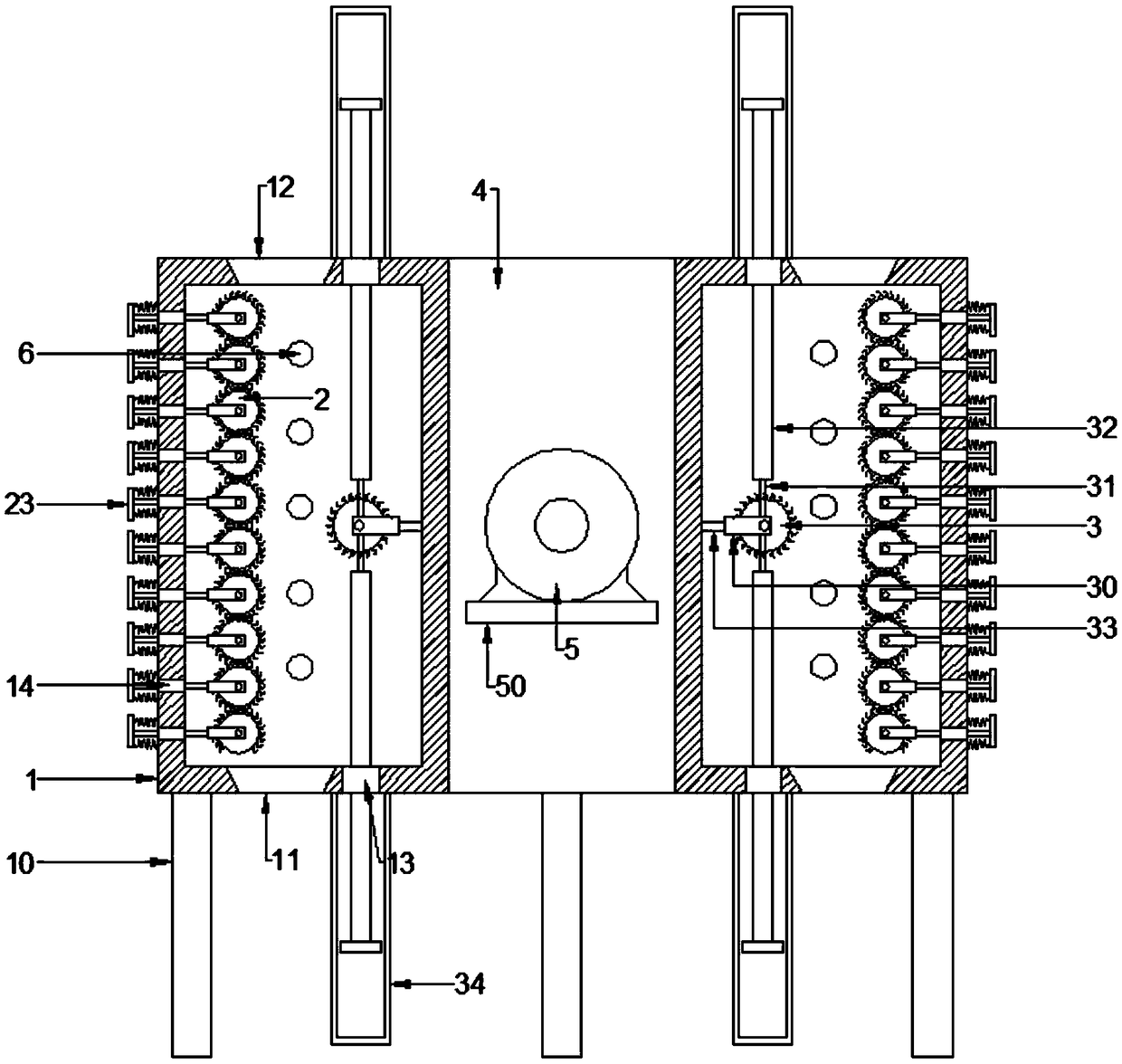

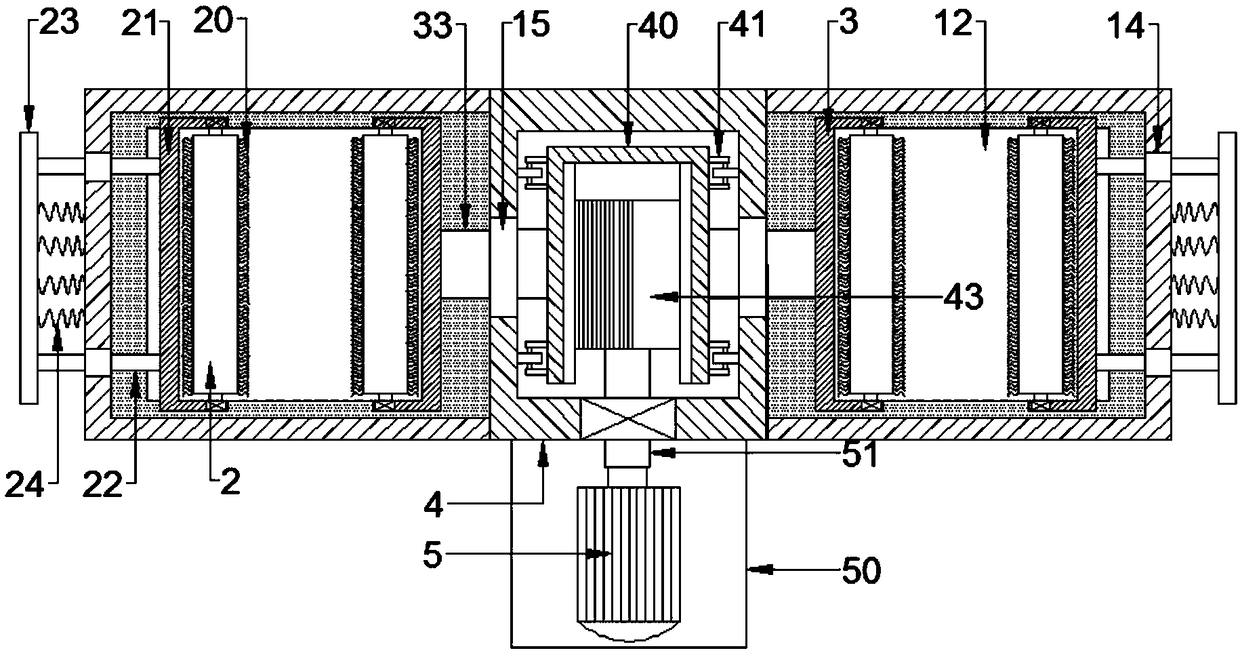

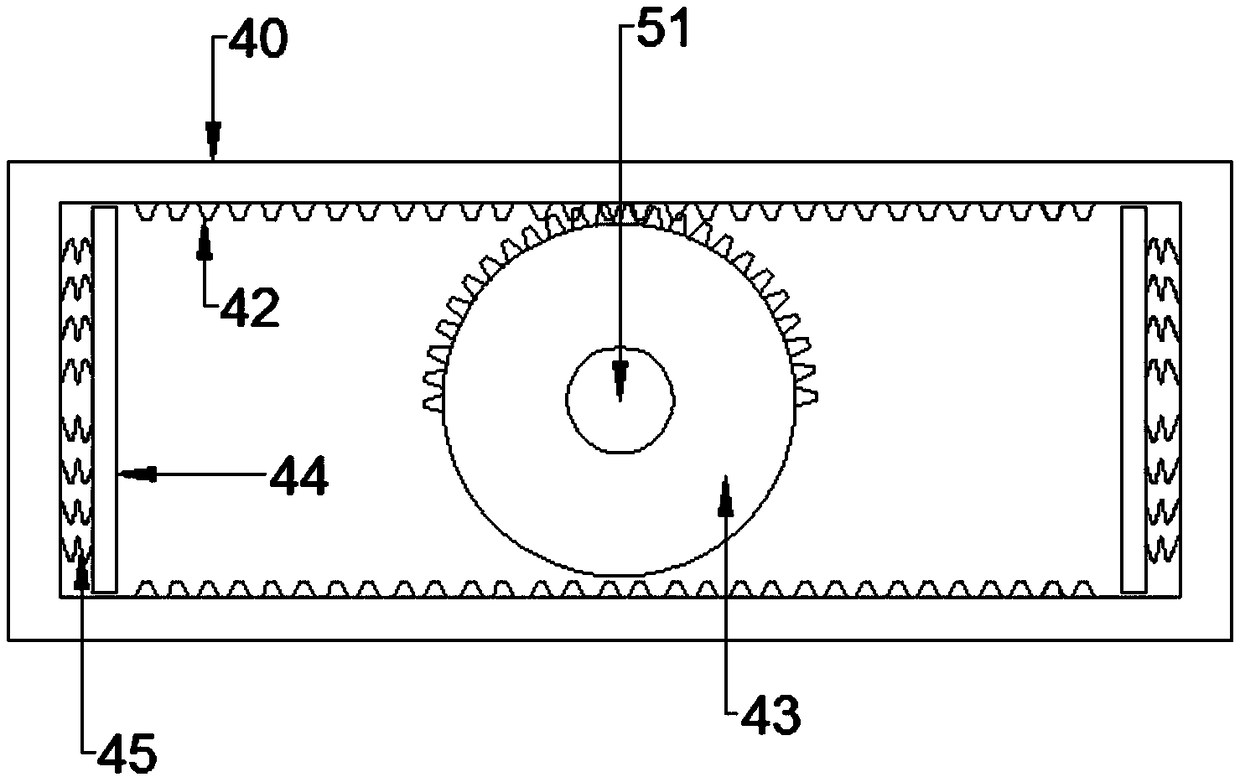

[0022] see Figure 1~4 , in an embodiment of the present invention, a potato rubbing mud removal device includes a rubbing mud box 1 and a driving box 4, and the mud rubbing box 1 and the driving box 4 are fixed on the ground by a plurality of support columns 10, and the driving box The left and right side walls of 4 are respectively fixed with a mud rubbing box 1, and the top surface and the bottom surface of the mud rubbing box 1 are respectively provided with a feed inlet 12 and a material leakage port 11, and the rear panel of the mud rubbing box 1 is provided with multiple An external water pipe mouth 6 used to be connected with an external water supply device, the junction of the mud box 1 and the drive box 4 is vertically provided with an up and down sliding opening 15 communicating with the mud box 1 and the drive box 4, the up and down A driving rod 33 is slidably worn in the sliding opening 15, and the outer end of the driving rod 33 is provided with a fixed main tur...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is:

[0032] The upper and lower sides of the follow-up scrubbing drum 2 are provided with limit slides 32 to prevent potatoes from being stuck, and the front and rear sides of the bottom of the limit slide 32 are fixed on the sides of the main turret 30 by two slide support rods 31. Above, the limit slide plate 32 is integrally slid and installed in the slide plate openings 13 respectively provided on the top surface and the bottom surface of the mud rubbing box 1. The slide plate openings 13 are located inside the feed opening 12 and the material leakage opening 11. The outer surface of the limit slide plate 32 is provided with a hairbrush for clearing mud, and the set limit slide plate 32 can slide up and down in the slide plate port 13 under the drive of the reciprocating sliding device along with the driven scrubbing cylinder 3; the limit slide plate 32 The length is less than the length of the support column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com