Nail box assembly and nail gun provided with same

A component and nail box technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of affecting the stability of needles and product quality, and achieve the effect of improving stability and convenience of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

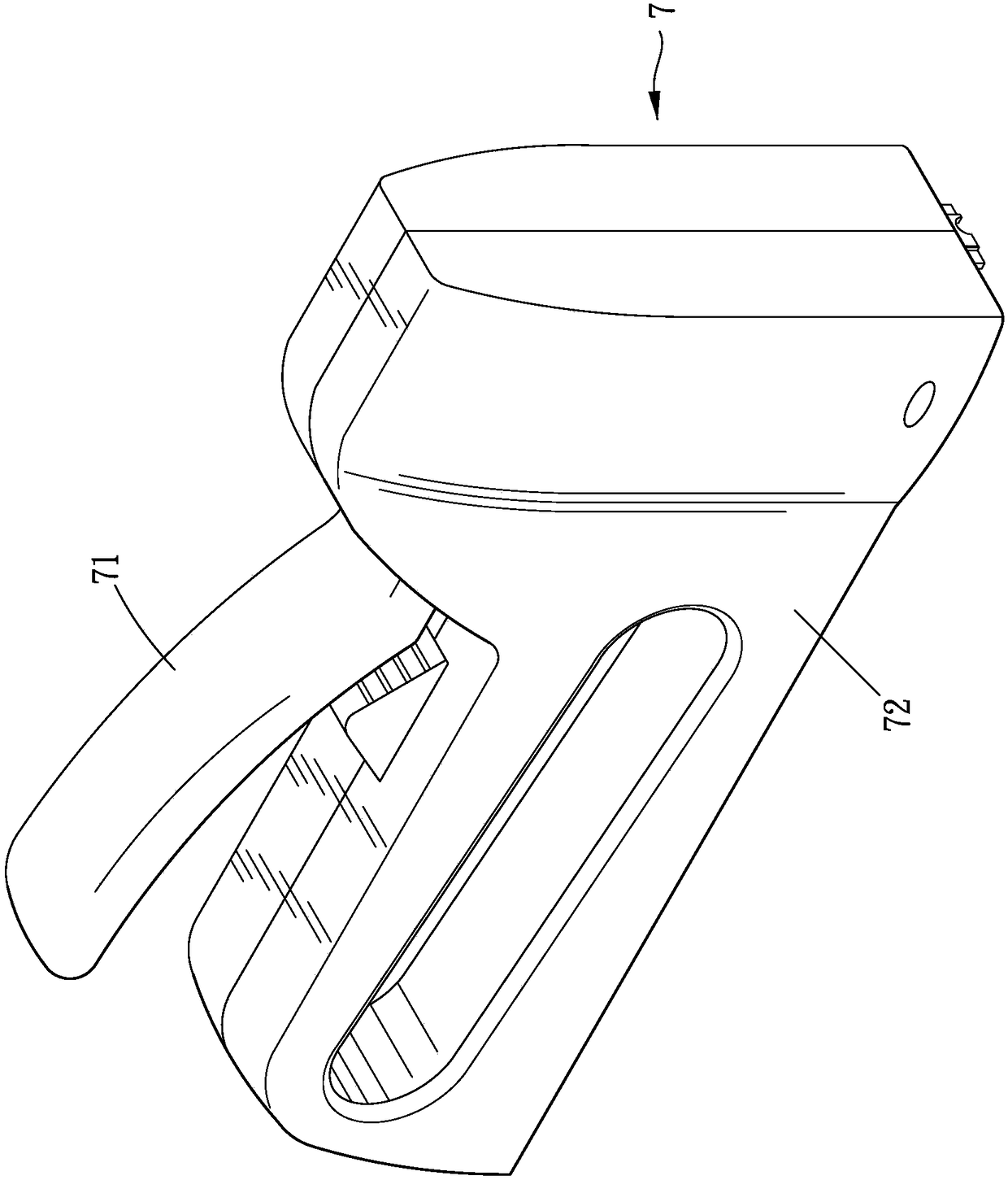

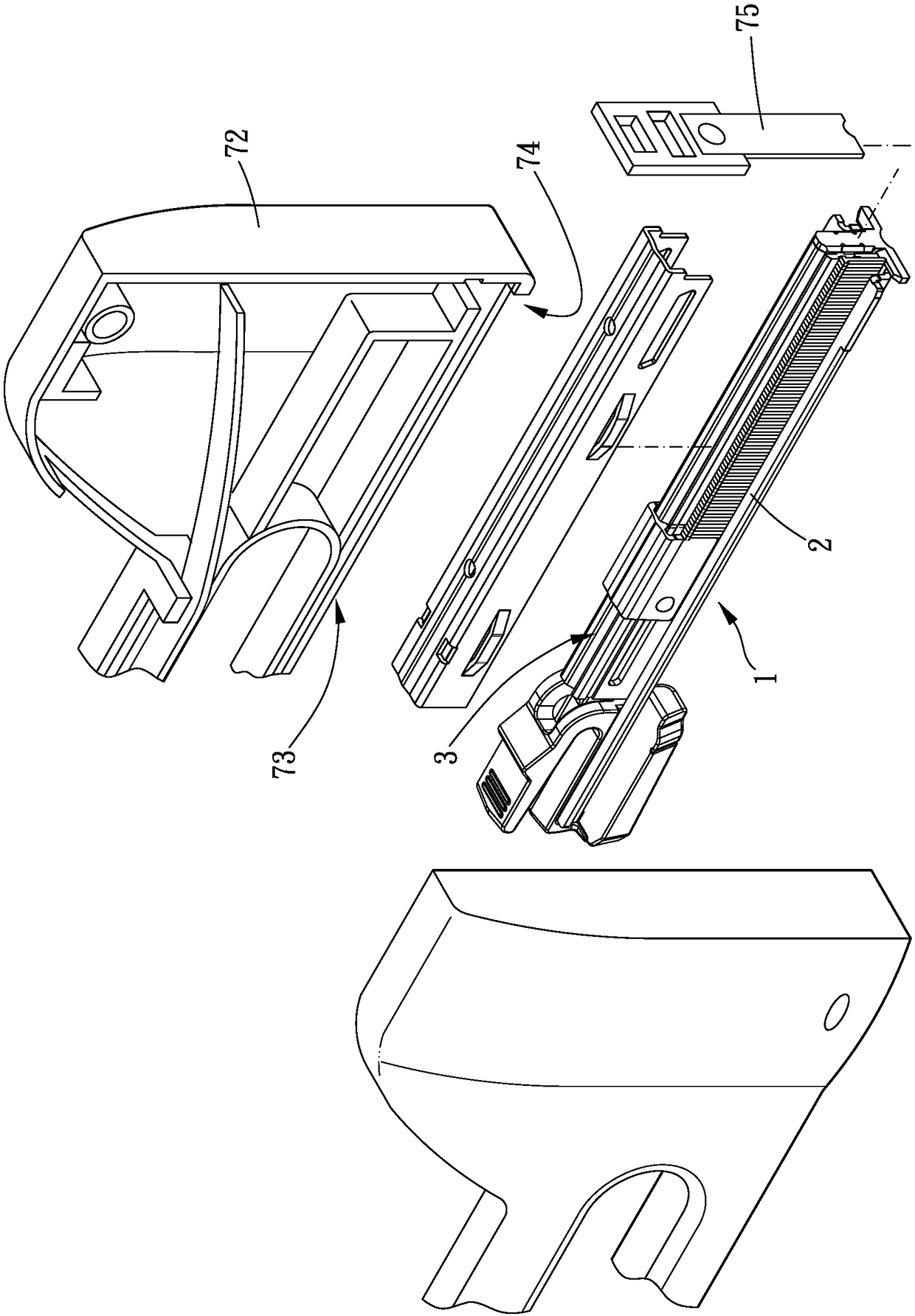

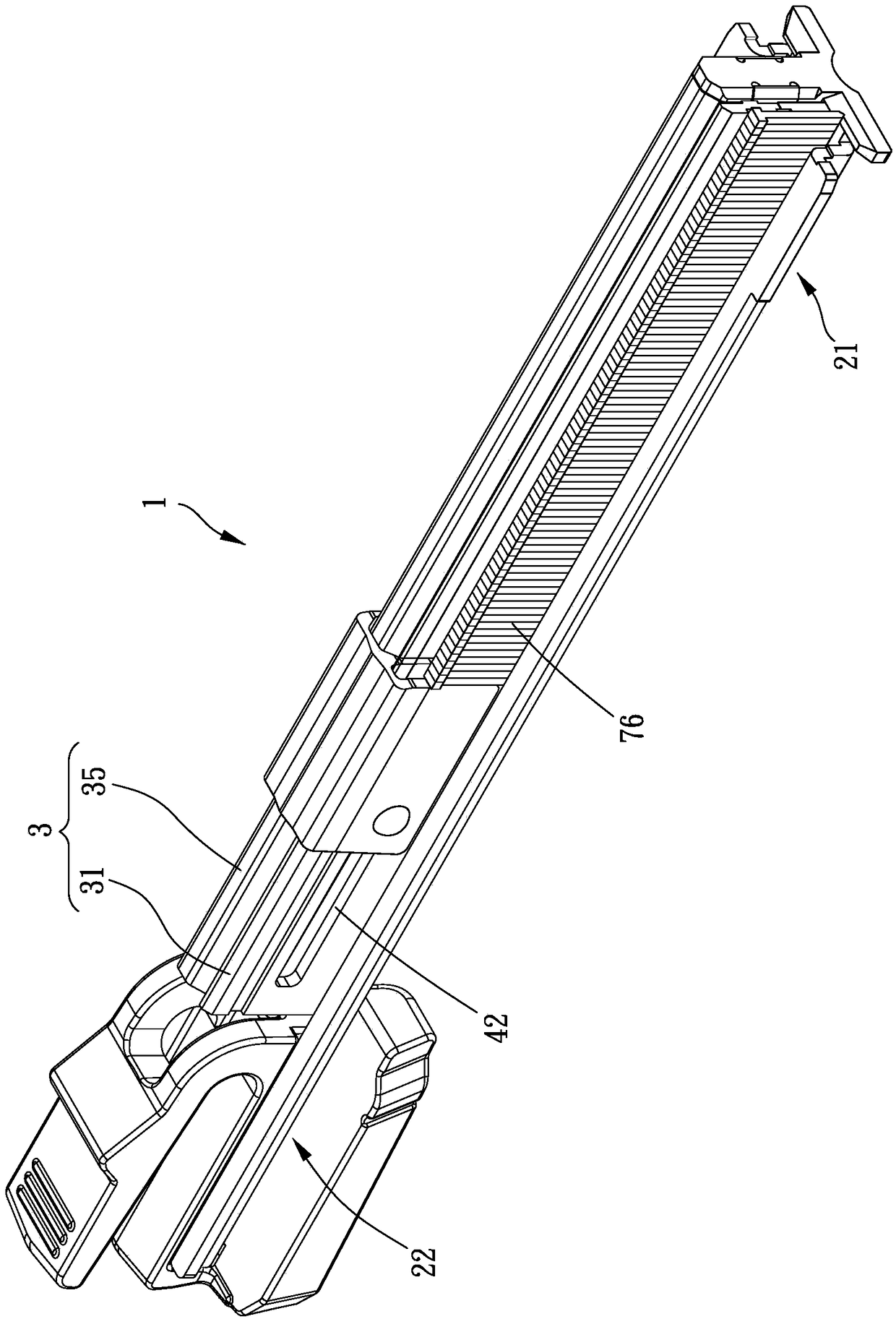

[0030] Please refer to Figure 1 to Figure 11 , which shows an embodiment of the nail magazine assembly and the nail gun 7 comprising it of the present invention.

[0031] The nail magazine assembly is provided on the nail gun 7 , and the nail magazine assembly includes: a body 1 and a nail pushing mechanism 4 . The body 1 is provided with a base 2 and at least one nail rail 3, the base 2 is provided with a first end 21 and a second end 22, the first end 21 is closer to the nail than the second end 22 A striking plate 75 of gun 7, this striking plate 75 is used for knocking the nail pin of a nail unit 76, defines the connecting line path of this first and second end 21,22 and is defined as a movement path 81, and this at least A nail rail 3 is disposed on the base body 2 and abuts against the nail unit 76 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com